Jingyi JY-30A3 automatic forward and reverse swirling/spinning oil mixer

SEJNYE JY-30A3 Automatic forward and reverse swirling/spinning mixerSPEC

JNYE JY-30A3 Automatic forward and reverse swirling/spinning mixerDetails

JNYE JY-30A3 Automatic forward and reverse swirling/spinning mixerPacking list

- SKU

- NB049342

- mixing time setting

- 2-30 minutes

- mixing Capacity

- 1-20L

- Mixed Weight

- 1-35kg

- revolution speed

- 100r/min-200r/min

- Rotation speed

- 200r/min-400r/min

- Available maximum barrel size

- Maximum barrel diameter 320mm

- Available barrel height range

- 50-390mm

- Power Supply

- 110V、220V、±10%、50/60HZ

- Motor Power

- 750W

- Net Weight of equipment

- 190kg

- Gross Weight

- 230kg

- Device size

- 1050 (H) x830 (W) x740 (D) mm

- Packaging Dimensions

- Height 1140mmx Width 900mmx Depth 810mm

Introduction

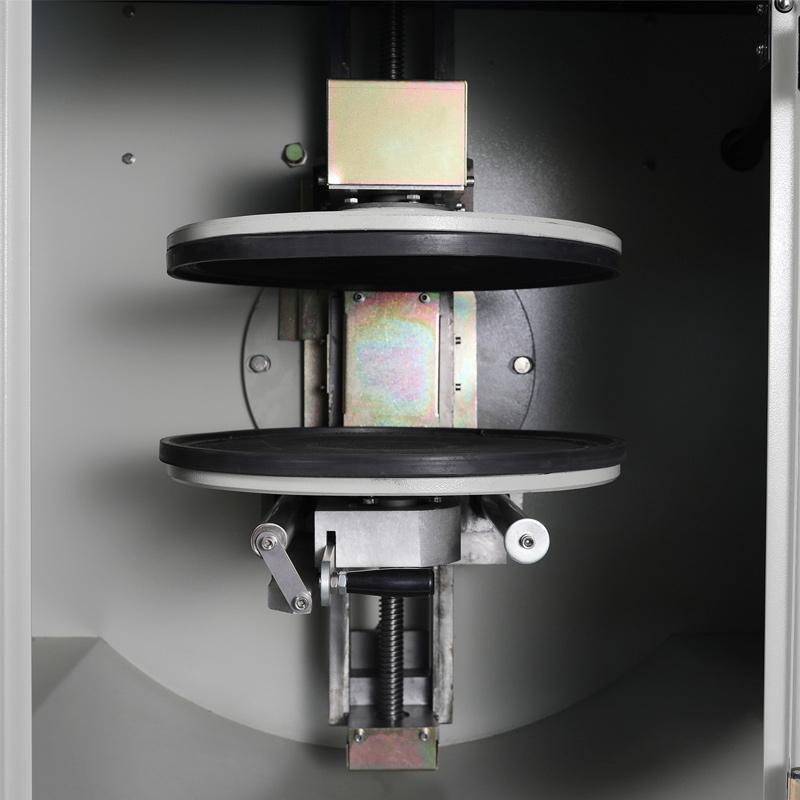

JY-30A3 Automatic Forward and Reverse Rotary Oil Mixer is an intelligent device specially designed for high-efficiency oil mixing, supporting 110V/220V power supply, 750W power drive, suitable for 1 - 20L, 1 - 35kg, maximum barrel diameter 320mm, barrel height 50 - 390mm packaging drums. With its 720° forward and reverse bidirectional rotation design, it completely reverses the situation of insufficient and time-consuming unidirectional mixing, and achieves fast and uniform mixing; The automatic intelligent clamping system can accurately apply force according to the size of the barrel to ensure stable clamping without damaging the barrel body; The advanced inverter speed regulation technology automatically identifies the drum specification and matches the appropriate speed to achieve the optimal mixing effect. The equipment is equipped with Chinese (English) digital tube, and the operation is clear and easy to understand; The chuck and roller design can be moved forward to make loading, unloading and movement easier; It has automatic shutdown protection for door opening and easy to remove the upper cover, which ensures safety and maintenance, and provides high-quality solutions for all kinds of oil mixing needs.

Features

The 720° positive and negative two-way rotation function solves the disadvantages of incomplete mixing and long mixing time of the one-way rotary machine, and makes the mixing effect faster and more uniform

Fully automatic clamping and loosening of the packaging barrel, intelligent control of the clamping force according to the size of the packaging barrel, to ensure that the clamped packaging barrel is stable and intact

Advanced frequency conversion speed regulation technology, intelligent identification of the size of the packaging barrel and automatic control of the corresponding speed, to ensure the best mixing effect

The clear and clear display of the digital tube in Chinese (English) makes the whole operation process clear at a glance and can be operated freely

The forward-moving lower chuck makes loading and unloading the drums easy and convenient

Equipped with rollers, it is convenient to move indoors, and there is no need to use a car, saving time and effort

Automatic shutdown protection device for door opening, safe and reliable

The upper cover can be removed for easy maintenance and replacement of parts

JY-30A3

JY-30A3