Xinlinte YJ300 High-Efficiency Oscillating Mixer, high-efficiency vibration dispersion, fixed frequency

SE

XinLinTe YJ300 High efficiency oscillatorSPEC

XinLinTe YJ300 High efficiency oscillatorDetails

XinLinTe YJ300 High efficiency oscillatorPacking list

- SKU

- NB049375

- Voltage

- 220V 50HZ

- Motor power

- 1100W

- Maximum load

- 30KG

- Shake space

- 350*350*320mm

- Step up the pressure

- Automatic, adjustable

- Operating Time

- Adjustable

- vibration frequency

- 50hz

- Safety Devices

- Emergency brake button

- Body Color Selection

- Blue standard or customer specified

- net Weight

- ≈260KG

- Dimensions

- 1100*700*660mm

Operating Principle

The dispersion disc turns two or more liquid and solid powder materials up and down vigorously in the container at high speed to produce strong collision and shearing effect, so that the aggregate is destroyed, and the purpose of rapid decomposition and uniform mixing is achieved, so that the insoluble material is dissolved at an accelerated rate.

Scope of application

In industries such as coatings and inks, there are many aspects that require dispersion testing under continuous controlled conditions. This High-Efficiency Oscillating Mixer is widely used in paint or ink systems to analyze the chromaticity of pigments, which is an important economic indicator for us to evaluate the performance of pigments. By dispersion, the adhesion of pigments is evaluated, the dispersion effect of dispersants is evaluated, and the grinding device is optimized for specific pigments and specified dispersion systems.

Features

The advantage of the YJ Oscillator is that a large number of samples can be dispersed under the same conditions, which increases the speed of testing and ensures reproducibility and repeatability. THE NUMBER OF SAMPLES DEPENDS ON THE SAMPLE TANK SIZE, WITH A MAXIMUM LOAD OF 30KG.

The device geometrically moves from back to front in the vertical direction along an elliptical trajectory, with a vibration range of 45 mm at no load and 32 mm at full load. The vibration frequency is about 660+40 times/min, 50Hz (40-60Hz) is adjustable, and the centrifugal force is 20 times the load.

The cooling unit consists of two rear-mounted low-pressure fans, which ensure that the temperature of the sample vessel is maintained at 10°C above room temperature. The cooling system automatically adjusts the fan power according to the operation of the equipment. Compared with other vibration dispersion devices, the YJ High-Efficiency Oscillating Mixer ensures that the test conditions and test results of the sample containers at each position are relatively independent and equal.

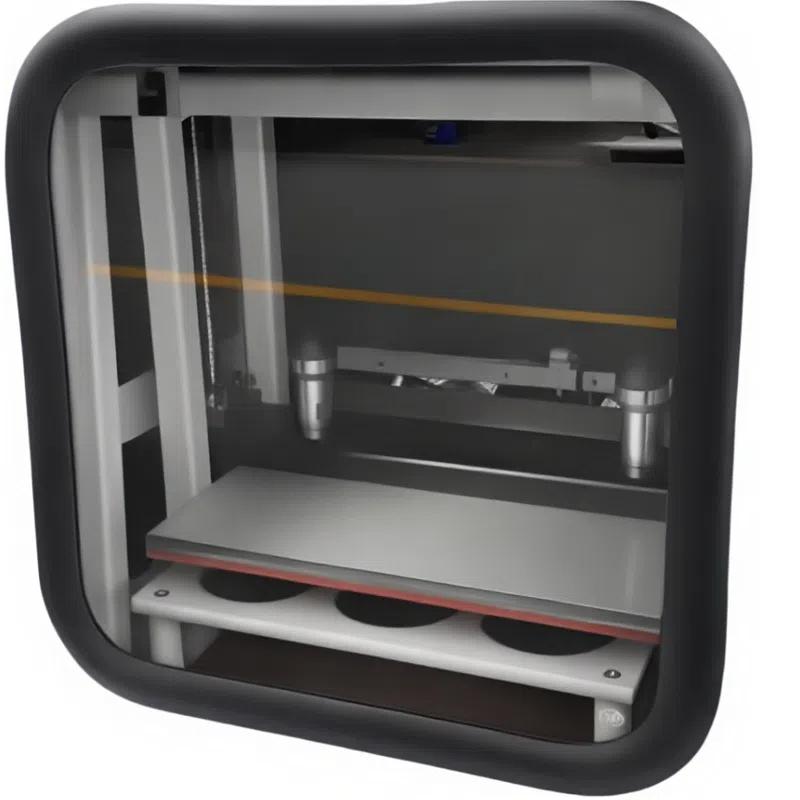

There is a completely enclosed container space, which on the one hand minimizes noise; On the other hand, in the event of a glass container bursting or chemical leakage, it can also be blocked to avoid contamination of the laboratory environment. Supplemented by a transparent observation window, you can see the operation of the experimental sample at any time.

Using the German Siemens PLC operation display system, the dispersion time can be conveniently preset. The display also shows the remaining dispersion time, the total operating time and, if required, the clamping time and the frequency of vibrations. The monitors are all in Chinese, which is simple and easy to understand. During the operation of the equipment, the equipment fault code is displayed at any time, and the problem of the equipment is judged by the fault code.

The operation is very convenient and the sample container (glass or plastic bottle) can be placed in the appropriate sample well in the sample holder. Close the sealed door and set the dispersion time and cooling level. Automatic clamping is adopted to start its dispersion movement. After 20 seconds, the cooling fan is activated to reduce the temperature of the dispersion chamber and the sample. When the preset dispersion time is reached, the device will automatically stop working.

YJ300

YJ300