Specifications

| detection range | (0~6000)mm |

| Frequency | (0.5~10)MHz |

| Speed of sound | (1000~15000)m/s |

| Dynamic range | ≥36dB |

| Vertical Linearity | ≤3.0% |

| Horizontal Linearity | ≤0.2% |

| Display resolution | 320*240 |

| resolution | >40dB(5P14) |

| Blind spot | 5MM |

| Sensitivity margin | > 60dB (200mm depth with 2 flat bottom holes) |

| digital suppression | (0~80) %, does not affect linearity and gain |

| video duration | without |

| electrical noise level | ≤10% |

| Probe type | Straight probe, oblique probe, dual crystal probe, penetration probe |

| gate | Inlet gate, loss gate; single gate reading, double gate reading |

| alarm | Beep alarm, LED light alarm |

| Flaw detection standard | Built-in common flaw detection standards in various industries, direct call, convenient and fast |

| Weld diagram | The weld shape parameters can be set, and the weld pattern and the position of the defect in the weld can be visually displayed during the flaw detection |

| Automatic calibration | Probe zero and probe angle (K value) Automatic calibration function; Speed of sound automatic measurement function |

| Memory | Real-time retrieval of the highest defect wave and recording of the peak defect echo |

| positioning | Real-time display of defect level, depth (vertical), sound path position |

| defect quantification | Real-time display of defect equivalent dB values |

| defect characterization | Through the echo envelope waveform, it is convenient for manual experience to judge |

| surface correction | For flaw detection of curved workpieces, the circumferential position of defects can be displayed in real time |

| DAC/AVG | Linear dispersion is automatically generated with unlimited sampling points, and can be compensated and corrected. Linear dispersion automatically floats with gain, automatically expands with sound path, and automatically moves with delay. AVG Linear dispersion can display any aperture |

| AWSD1.1 | American Welding Society standard provides a dynamic reflection "defect rating" for various AWS weld inspection applications. Avoids manual calculations and improves inspection efficiency (optional) |

| Crazing bathymetry | Automatic measurement and calculation of crazing depth using diffraction waves |

| Door widening | Amplify echo details for easy echo analysis |

| continuous recording | Record waveforms in real time, store and playback waveforms |

| waveform freezing | Freeze the waveform displayed on the screen for easy defect analysis |

| echo coding | Display 1 to 6 echo display areas in different Colors, better distinguish between primary and secondary waves, easy to determine the location of defects |

| B-scan | (Ordinary B-scan) Real-time scanning and cross-sectional display make detection results more intuitive |

| Environmental temperature | (-10~50)℃ |

| Relative Humidity | (20~95)%RH |

| Power Supply | Direct current (DC) 9V; lithium battery works continuously for more than 10 hours |

| Power saving method | Low power design |

| Working time | More than 10 hours |

| Protection level | IP64 |

| Communication interface | USB2.0 high-speed communication transmission interface |

| PC software | Yes. |

| working language | Chinese |

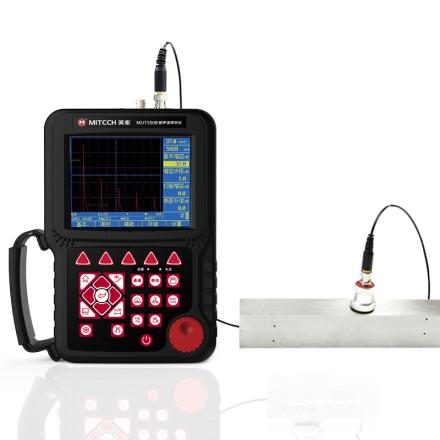

| exterior size | 263×170×61(mm) |

| Machine Weight | 5.2KG |

Packing list

After-sales instructions

Warranty days: 365 days

[Note] For after-sales services outside the Chinese mainland, if the instrument requires repair, the shipping and possible associated taxes shall be borne by the sender. Generation address of the manual: http://en.nbchao.com/p/49540/Specification.html , which is only used by users who purchase commodities from the NBCHAO.