AMITTARI Accessories Shore Shore Durometer measurement stand

AMITTARI accessories Shore Shore Durometer measurement standSPEC

AMITTARI accessories Shore Shore Durometer measurement standDetails

AMITTARI accessories Shore Shore Durometer measurement standPacking list

- SKU

- NB049662

Product Description:

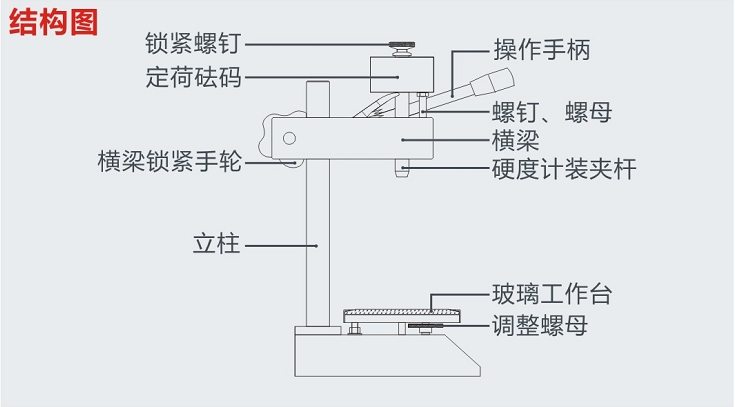

The upper end of the SHS-1 Shore Hardness Tester measuring bench is equipped with a special fixed load weight to measure the hardness value of rubber; The use of Shore Hardness Tester test bench can effectively improve the accuracy of rubber hardness measurement, through the frame on the Hardness Tester pressure needle axis to apply the test force, so that the Hardness Tester pressure foot pressure on the sample, so as to achieve a more stable and accurate hardness value. The Shore Hardness Tester test rack is equipped with the corresponding fixed load weight at the upper end of the Hardness Tester according to its clamping Hardness Tester, and the rack can be configured with eight models of Anmiao Shore Hardness Tester: A-type, B-type, C-type, D-type, DO type, E-type, O-type, 00 type, etc.

How to use:

The Hardness Tester is stably connected through the connecting hole at the lower part of the clamping rod of the Hardness Tester, and the Hardness Gauge block of the accessory in the Hardness Tester packaging box is placed on the glass work surface. Press down on the handle to make the hardness block press down under the action of the fixed load weight, and align the pressure of the Hardness Tester and enter the hole of the measuring block, when the Hardness Tester is pressed enough to fully contact the plane of the measuring block. At this time, the hardness count value should be indicated within the hardness of the hardness measurement hole, if it is not indicated within the hardness ±, the indication value can be adjusted to two adjustment nuts through the two adjustment nuts under the glass table, and the indication value can be adjusted to within 100+1. If the hardness block Tester is not equipped with a Hardness Gauge block, press down the operating handle to make the Hardness Tester press on the work surface under the action of the fixed load weight. The Hardness Tester is fully pressed into full contact with the flat surface of the glass table. At this time, the hardness count value should be indicated within 100+1, if it is not indicated within 100+1, the hardness can be found within 1 through the identification under the glass table. The test sample is placed on the glass table, the operating handle is pressed, and the hardness value is read at the specified time after the Hardness Tester is in complete contact with the tested sample under the action of the fixed load weight, and the reading time of thermoplastic rubber is 15 seconds, and the reading time of vulcanized rubber or unknown type rubber is 3 seconds; The microporous material is read within 1 second after the Hardness Tester is in full contact with the test specimen and subjected to the test load, if a different test time is used, it should be stated in the test report,

Precautions

The fixed load weights configured with this rack only match the company's Hardness Tester, please adjust the total weight of the weights according to the requirements in other hardness meters of the device.

1. The test should be without vibration when using this frame, and the Hardness Tester should be pressed to the sample at a maximum speed of 3.2 mm/s.

2. The requirements and adjustment of the sample during the test shall be carried out according to the corresponding standard of the sample.

accessories

accessories