MODERNER SCL-200 elongation Measurement Instrument

Moderner SCL-200 Elongation Measurement InstrumentSPEC

Moderner SCL-200 Elongation Measurement InstrumentDetails

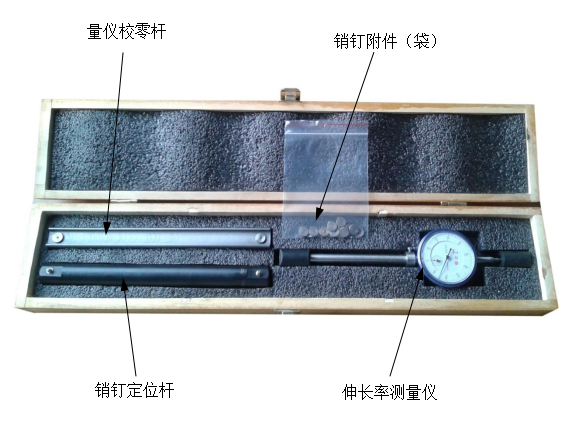

Moderner SCL-200 Elongation Measurement InstrumentPacking list

- SKU

- NB049675

- Measurement range

- 200±5mm

- Zero rod size

- 200±0.5mm

- Positioning rod size

- 200±1mm

- Pin bonding surface

- Φ10mm

- relevant standards

- JC/T 550-2019,BS EN 1903:2008

The SCL-200 elongation measuring instrument is designed and manufactured according to the requirements of the British standard BS EN 1903:2008 "Adhesives - Test Methods: For Plastic or Rubber Floor Coverings and Wall Coatings - Dimensional Change Determination after Accelerated Aging". The method is to fix the measuring pins with adhesive on the test sample at a certain interval, measure the dimensional change of the pins before and after blast heating, and obtain the percentage change (elongation) of the dimensions through a simple calculation. The instrument is portable, simple to operate, and easy to read.

Operational summary

1. Make a test sample according to the relevant technical regulations of the product to be tested by the user, and the recommended size of the test sample is 250×250mm.

2. Fix the pin attachment to the four corners of the test template with adhesive, the pin is about 25mm away from the edge of the test plate, and the pin spacing is about 200mm with the pin positioning rod.

3. Use the calibration rod to zero the dial of the elongation measuring instrument (note: check the zero before each measurement). Large dial * small scale 0.01mm, the length decreases the dial indication increases, and the length increases the dial indication decreases.

4. Measure the initial spacing of the four pins with an elongation measuring instrument that has been zeroed, and make a record.

5. According to the relevant technical regulations of the product to be tested, the blast heating test sample is carried out to the specified temperature.

6. Measure the spacing of the four pins after heating with an elongation measuring instrument that has been zero, and make a record.

7. The elongation of the corresponding two pins before and after heating is obtained by the following formula:

Elongation = (Difference between the spacing before and after heating/200)*100%

(In fact, as long as the difference between the spacing before and after heating is divided by 2, the percentage elongation is obtained).

SCL-200

SCL-200