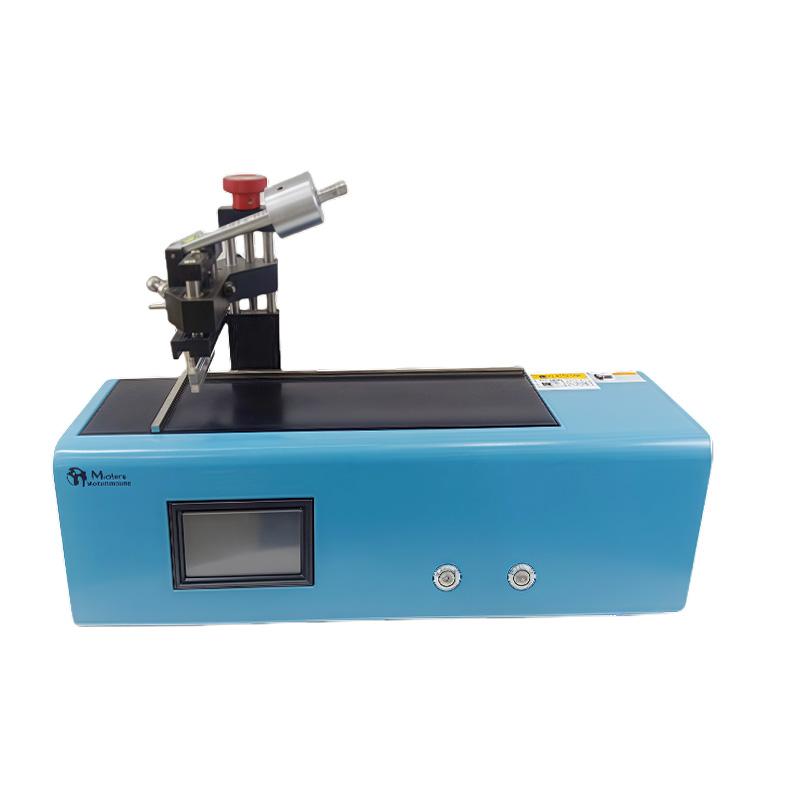

MODERNER ADM-III automatic grinding fineness gauge

Moderner ADM-III Automatic scraperSPEC

Moderner ADM-III Automatic scraperDetails

Moderner ADM-III Automatic scraperPacking list

- SKU

- NB049682

- Drawdown blade speed

- 0.5~ 150Mm/s can be set arbitrarily

- Drawdown blade maximum stroke

- 225mm

- Drawdown blade load

- 1.75/2/2.25/2 5/2.75/3/3.25 kg (small Weight); 3.5/4/4.5/5/5.5/6 kg (large Weight)

- Platform size

- 300*100mm

- Power Supply

- 100~240VAC 3.0A 50/60Hz

- Dimensions

- 540*230*365mm

In the production process of chemical raw materials such as coatings, pigments and inks, the use of scraper Fineness Meter to determine the degree of material dispersion is a common method to evaluate the dispersion, and it is one of the standardized methods for quality control. However, in order to obtain a consistent determination of the degree of dispersion, it is necessary not only to have well-trained and experienced operators, but also to have operational fluctuations between operators within the allowable tolerance. ADM-III automatic scraper is a new tool to improve the evaluation method of scraper Fineness Meter, this machine uses automatic scraper movement to complete the fineness scraper operation, so as to avoid the error caused by the scraper operation between personnel and improve the repetition of judgment results.

How to use:

1. ADM-III is suitable for most commercially available Grinders and scrapers. Scrapers and scrapers can be purchased separately.

2. The height adjustment of the scraper must refer to (scraper height setting and assembly).

3. Make sure that the slide is in the rear position, and the scraper lifting handle is at the 9 o'clock position.

4. Place the scraper on the machine table.

5. Please wipe the scraper and scraper with an appropriate solvent to ensure that there is no dust or lint on the scraper and scraper.

6. Place a small amount of specimen on the scraper path.

7. Move the slideway and move the scraper in front of the sample to be measured.

8. Gently rotate the lifting handle of the scraper to the direction of 3 o'clock to ensure that the speed of the scraper is not too fast, so as not to damage the scraper and scraper.

9. Press the Run button and the slide will move forward.

10. When the scraper is close to the tail of the scraper, quickly press the Stop button. Turn the scraper lift lever to the 9 o'clock position, remove the scraper, and manually move the slide to the rear. If the stop button is not pressed, the machine will run to the limit switch and stop automatically.

11. Read the data on the scraper Fineness Meter.

12. Clean the scraper and scraper.

ADM-III

ADM-III