HuiNuo TM3100H drawdown Bar & blade heating Coater Spreader 200 ℃

SEHuiNuo TM3100H Automatic Film ApplicatorSPEC

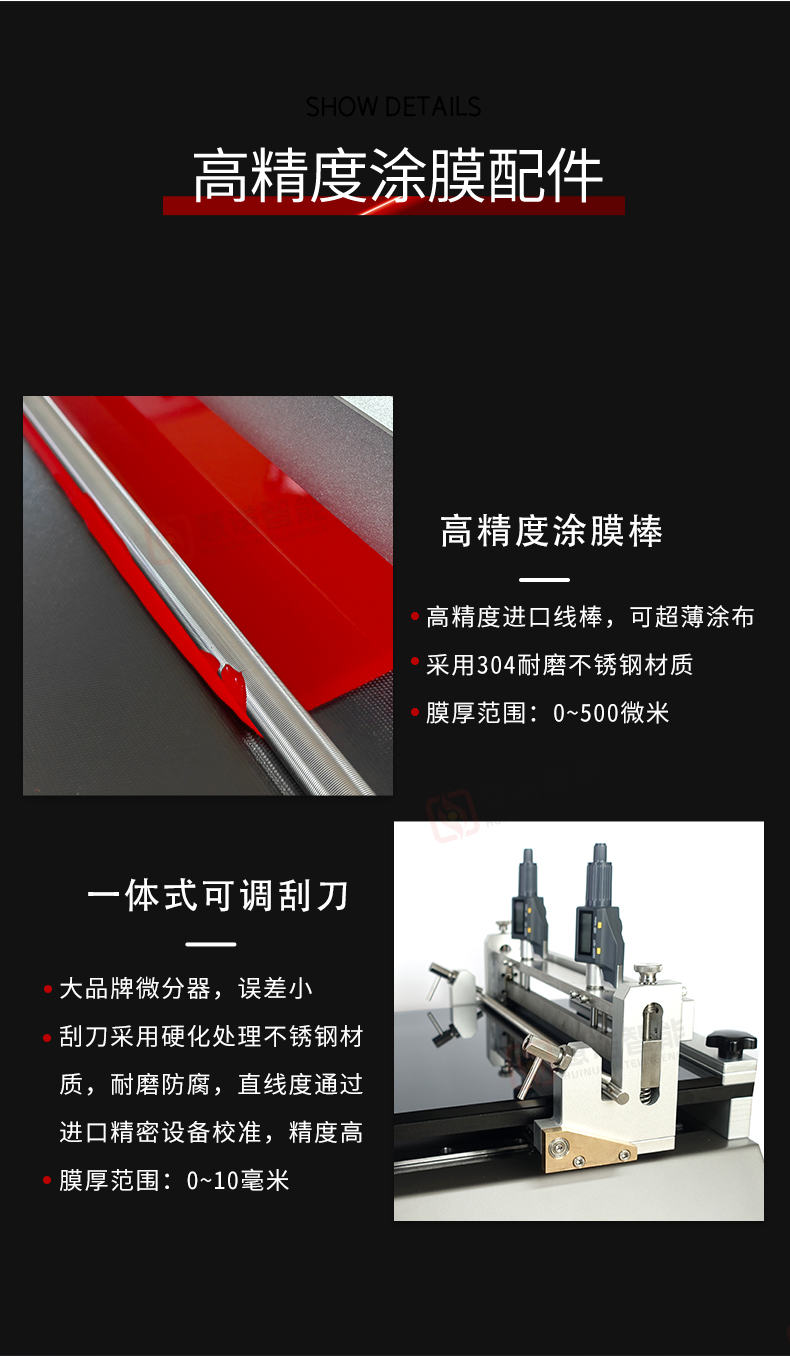

HuiNuo TM3100H Automatic Film ApplicatorDetails

HuiNuo TM3100H Automatic Film ApplicatorPacking list

- SKU

- NB049690

- Coating Method

- Rod + drawdown blade Spreader

- Coating Speed

- 1~ 300Mm/s stepless speed regulation (can be customized)

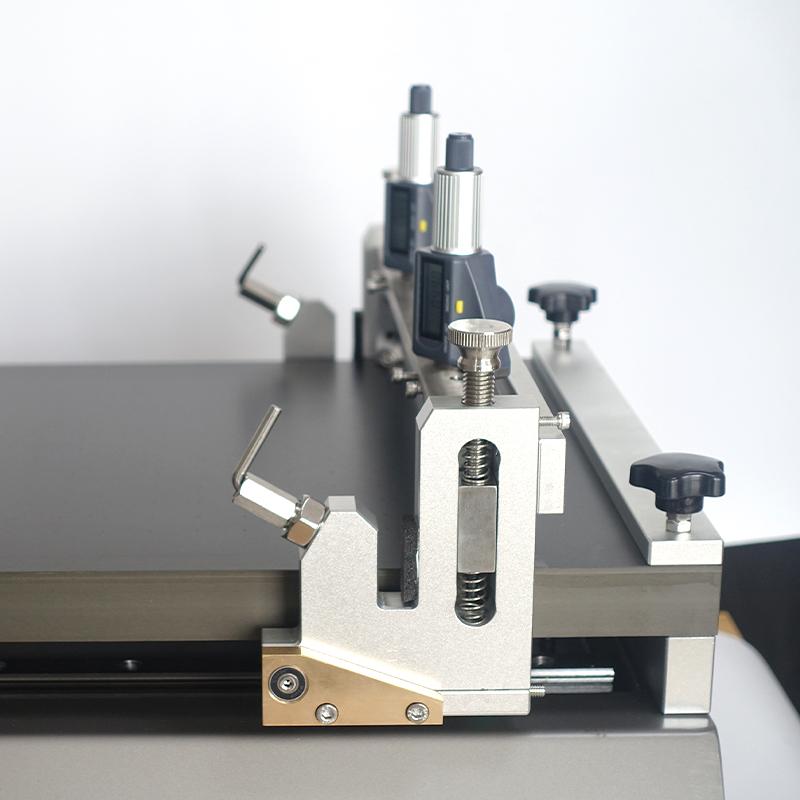

- Substrate clamping method

- fixture

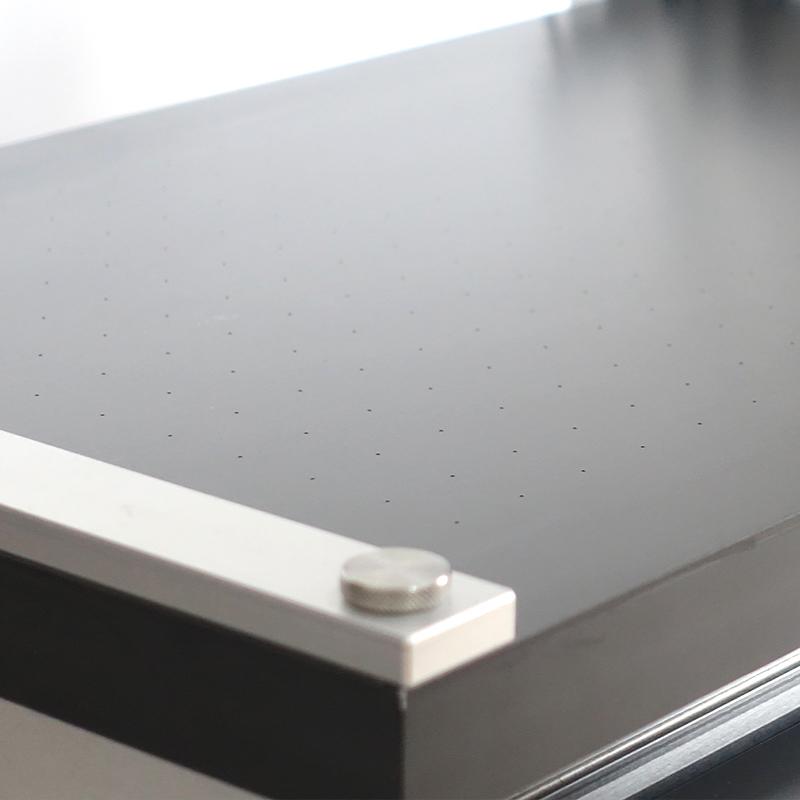

- Coating table material

- Surface hard treatment aluminum alloy

- Coating table size

- 300*600mm

- Effective coating Area

- 300mm*400mm

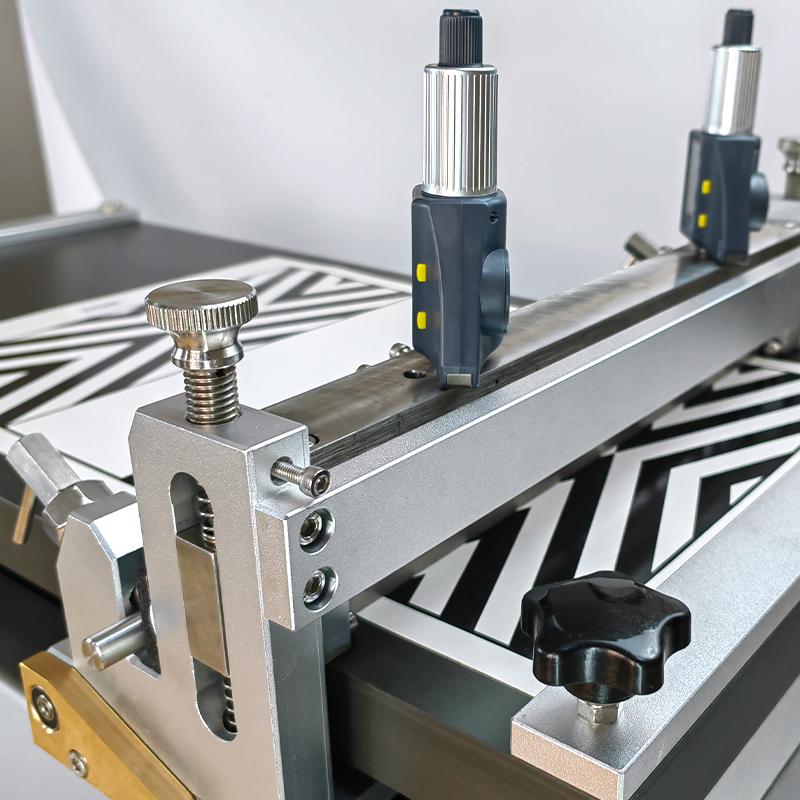

- Meyer rod coating thickness Range

- Different bar numbers Film thickness is different, with high Accuracy imported bar

- Meyer rod coating Accuracy

- ±0.001mm

- Drawdown blade Spreader Film thickness range

- 0.1~ 10Mm (clamshell design is easy to clean)

- Drawdown blade material

- Die steel

- Drawdown blade Spreader width

- 300mm

- Drawdown blade Spreader Accuracy

- ±0.003mm

- Heating method

- Mica sheet heating (optional graphene heating, faster thermal conductivity)

- Heating temperature range

- RT +~ 200 ℃ (can be customized)

- Temperature Uniformity

- ±1℃

- power

- 1800w

- operating language

- Chinese (can be customized in English)

- Display

- Color LCD touch screen

- Host Power Supply

- 100V~220V/50~60HZ

- Dimensions

- 658*438*400mm

Product Overview

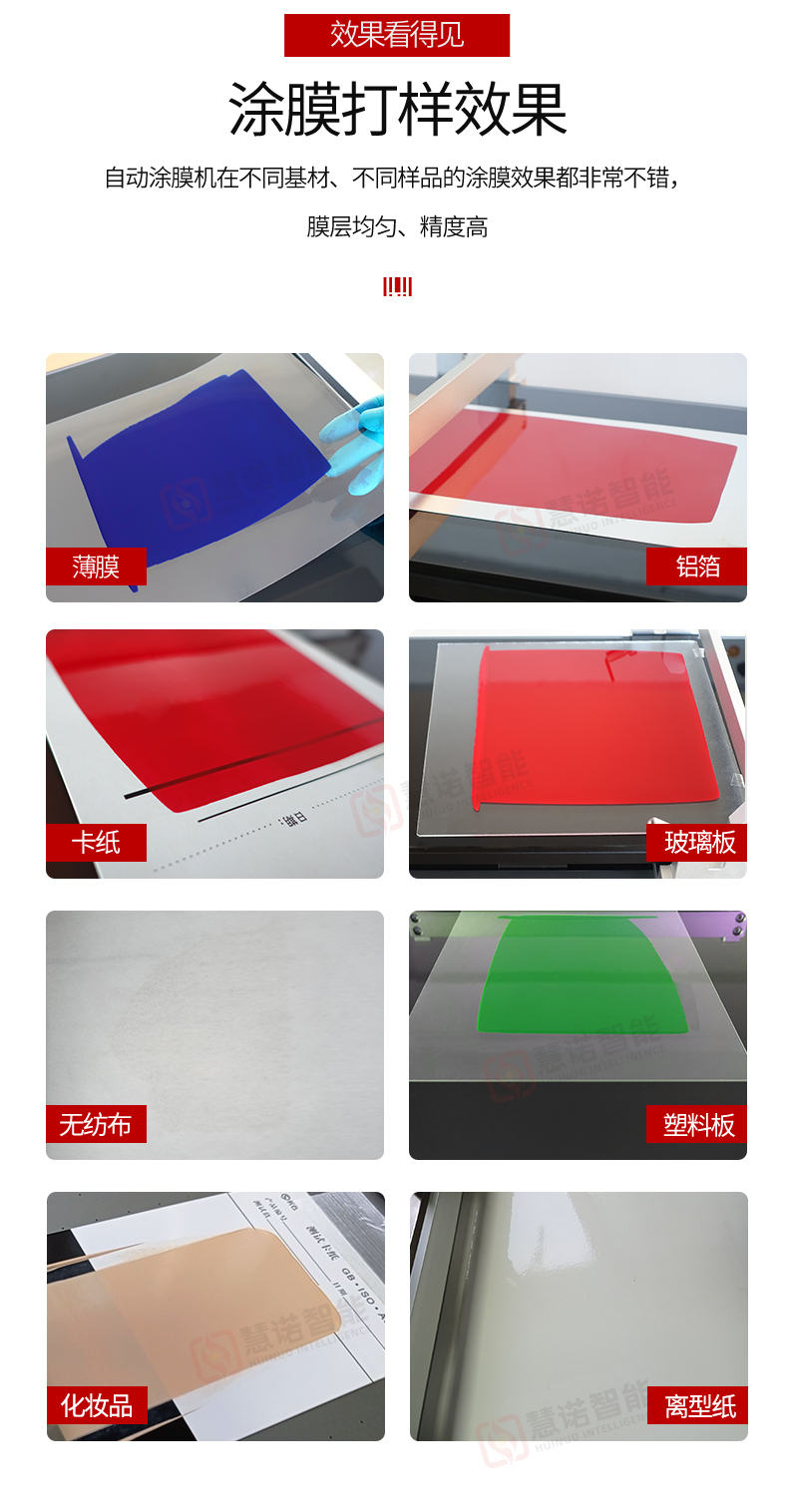

The automatic film coating machine is a device used to coat the film in the laboratory, replacing the manual coating film, and the coating film is carried out automatically, so as to improve the accuracy and efficiency of the coating film. The working principle of the experimental automatic film coater is to evenly coat the sample on the substrate by controlling the coating head and coating parameters to form the desired film.

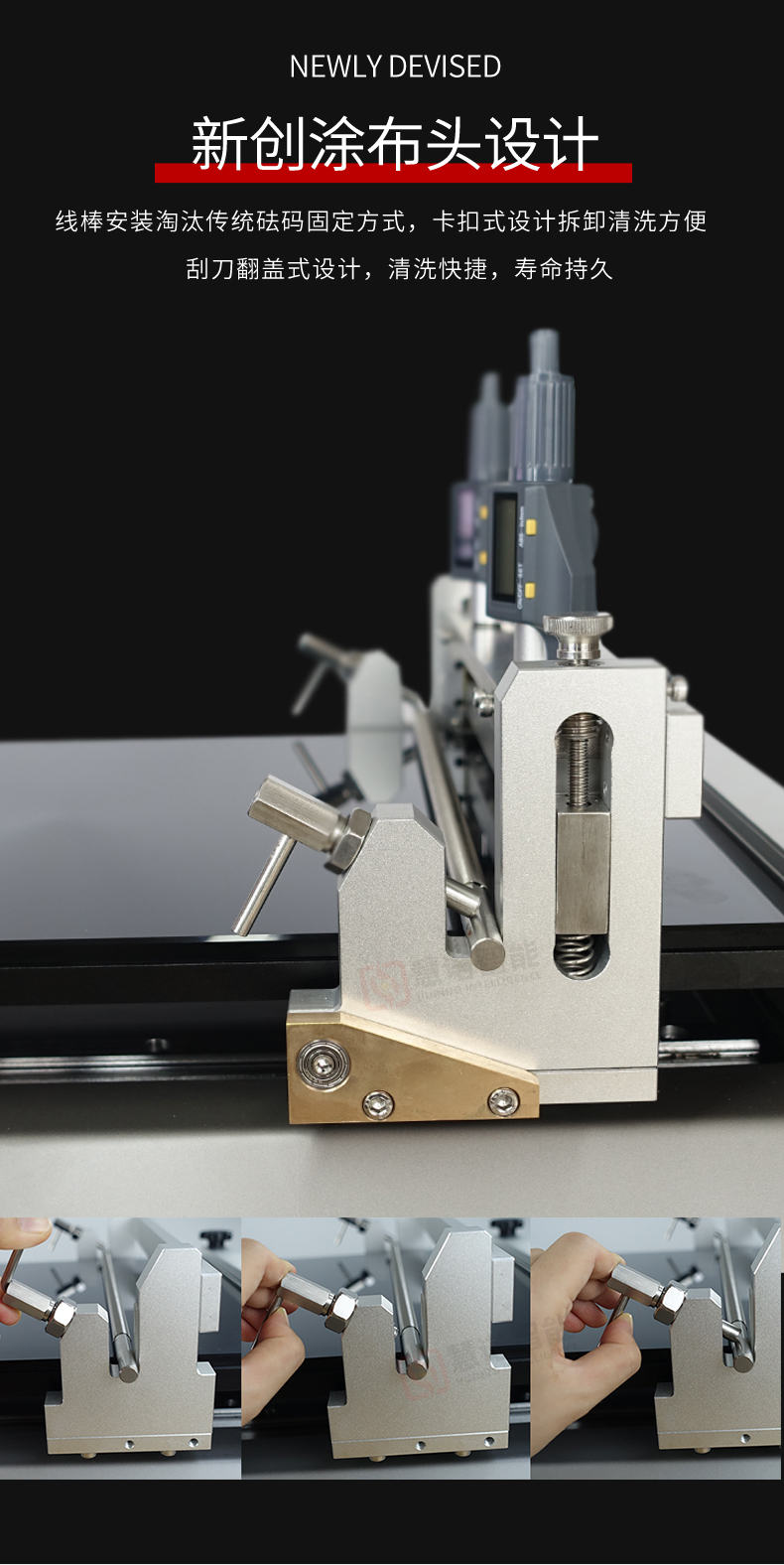

This coating machine is a wire rod scraper coating machine, using two types: wire rod and scraperCoating methodwith heating and drying function. The newly created wire rod installation method and clamshell scraper head of the film coating machine greatly improve the coating efficiency, easy to clean, and have the functions of speed control and coating length adjustment, which is suitable for high-precision automatic coating in the laboratory, and film proofing in university research institutes, new materials, lithium batteries, glue, resin and other laboratories.

Product Use:

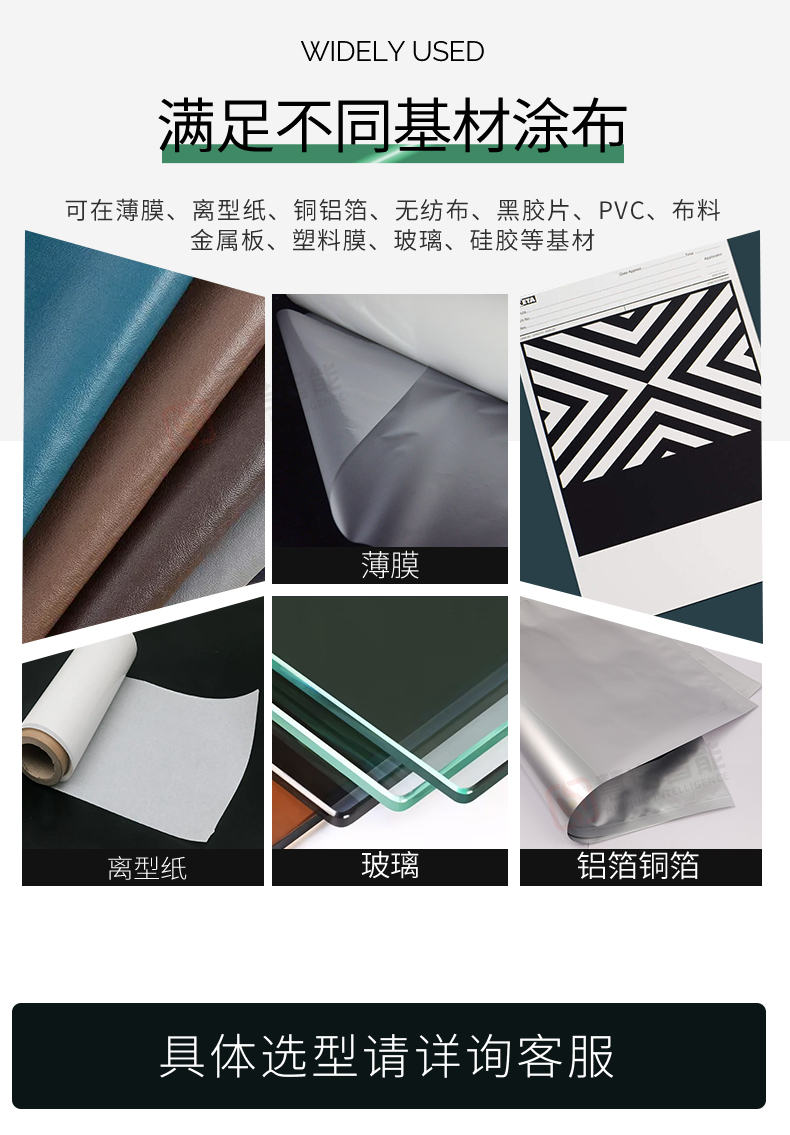

The film coating machine is suitable for coating samples of coatings, inks, paints, pastes, lithium batteries, pressure-sensitive adhesives, resins, glues, polymer materials, chemicals, etc., and can be scraped on glass, cardboard and cloth.

Features:

1)The surface is hard treated aluminum alloy countertop, with high hardness and wear-resistant, and the flatness of the table is tested by imported high-precision instruments.

2) Big brand differential regulator, high film thickness control accuracy

3) Clamshell scraper coating head, easy to clean

4) Equipped with high-precision Film Applicator, the original imported wire rod coating film is uniform and has high precision

5) Touch screen control panel, easy to operate

6) The coating length and coating speed can be adjusted freely

7) With heating function, it is suitable for hot melt adhesive and other coating films.

TM3100H

TM3100H