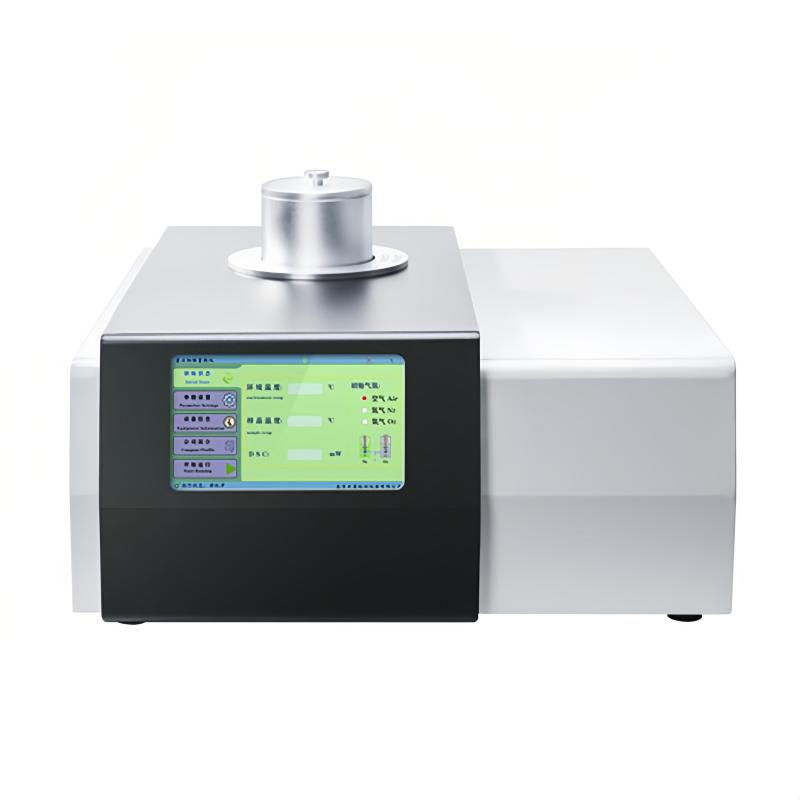

DZ-DSC100A Differential Scanning Calorimeter RT +~ 600 ℃ Customized

SEDaZhan equipment DZ-DSC100A Differential Scanning CaloriMeter - CustomizedSPEC

DaZhan equipment DZ-DSC100A Differential Scanning CaloriMeter - CustomizedDetails

DaZhan equipment DZ-DSC100A Differential Scanning CaloriMeter - CustomizedPacking list

- SKU

- NB049693

- temperature range

- Room temperature~ 600 ℃

- Temperature sensitivity

- 0.01℃

- Temperature Fluctuation

- ±0.1℃

- Temperature, repeability

- ±0.1℃

- Heating rate

- 0.1~100℃/min

- data scanning

- Heating scan, thermostatic scan

- DSC range

- 0~±500mW

- DSC resolution

- 0.01uW

- DSC sensitivity

- 0.001mW

- Power Supply

- AC220V/50Hz or custom

- Atmosphere control gas

- Nitrogen and oxygen (automatic instrument switching)

- gas flow rate

- 0-200mL/min

- gas pressure

- ≤0.5MPa

- display mode

- 24Bit color, 7-inch LCD touch screen display

- parameter standard

- Equipped with reference materials (indium, tin), users can adjust the temperature by themselves

Product Introduction

DSC is a high-precision differential display, and the sensor is made of imported E-couple, which has high sensitivity. Signal acquisition circuit shielding protection, strong anti-interference, high baseline stability.

The differential scanning calorimeter is a touch screen type, which can be used for glass transition temperature test, phase transition test, melting and enthalpy value test, product stability, curing, oxidation induction period test, oxidation induction temperature, etc. Wide range of applications

Technical features:

1. Industrial-grade 7-inch touch screen, display rich information.

2. Brand new metal furnace structure, better baseline and higher precision. The heating adopts the indirect conduction method, which has high uniformity and stability, reduces pulse radiation, and is better than the traditional heating mode.

3. USB communication interface, strong versatility, reliable and uninterrupted communication, support self-recovery connection function.

4. Automatically switch between two channels of atmosphere flow, fast switching speed and short stability time. At the same time, a shielding gas input is added.

5. The software is simple and easy to operate.

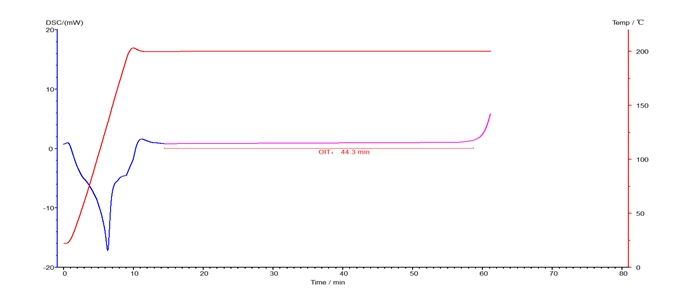

Test Map:1. Oxidation period test of PE, PPR and other pipes

Oxidation induction time (OIT) is measured by DSC (Differential Scanning Calorimetry). The specimen is usually heated to a defined temperature and constant temperature under a nitrogen atmosphere, and then switched to an oxygen atmosphere, after which the material begins to oxidize and release heat. This release heat is detected by the sensor, and through software analysis, the induced oxidation time (OIT) is obtained, and the length of the oxidation induction time is a parameter of the oxidative decomposition resistance of the reactive material, or it is very meaningful, and usually buried plastic pipes must detect this parameter.

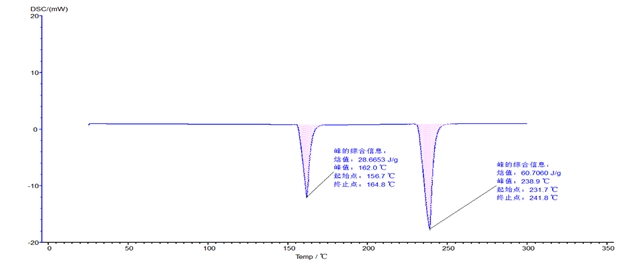

Melting point and enthalpy test (thermal stability test)

The melting point is the temperature at which a solid transforms its state of matter from a solid state or melts it into a liquid state. The test of enthalpy value is also suitable for the test and analysis of crystallinity

Meets standards

GB/T 33466.1-2016 Rigid polyvinyl chloride pipes -- Differential scanning calorimetry (DSC) Part 1: Measurement of processing temperature

GB/T 40271-2021 Test methods for textile fiber identification -- Differential scanning calorimetry

GB/T 41928-2022 GB/T 41928-2022 Plastics -- Epoxy resins -- Differential scanning calorimetry (DSC) determination

GB/T 19466.1-2004 Plastics – General principles for differential scanning calorimetry (DSC).

GB/T 19466.4-2016 Plastics – Differential scanning calorimetry (DSC) – Part 4 - Determination of specific heat capacity

GB/T 19466.5-2022 Plastics – Differential scanning calorimetry (DSC) – Part 5: Determination of characteristic reaction curves temperature, time, reaction enthalpy and conversion rate

GB/T 19466.2-2004 Plastics – Differential scanning calorimetry (DSC) – Part 2: Determination of glass transition temperature

GB/T 19466.3-2004 Plastics – Differential scanning calorimetry (DSC) – Part 3: Determination of melting and crystallization temperature and enthalpy

DZ-DSC100A

DZ-DSC100A