DZ-TGA103 Thermal Gravimetric Analyzer RT +~ 1350 ℃

SEDaZhan equipment DZ-TGA103 Thermal Gravimetric AnalyzerSPEC

DaZhan equipment DZ-TGA103 Thermal Gravimetric AnalyzerDetails

DaZhan equipment DZ-TGA103 Thermal Gravimetric AnalyzerPacking list

- SKU

- NB049700

- Temperature range

- Room temperature -1350 ℃

- Temperature Resolution

- 0.01℃

- Temperature Fluctuation

- ±0.1℃

- Heating rate

- 0.1~100℃/min

- Temperature control method

- PID algorithm control, heating, thermostatic

- Balance Measurement range

- 0.01mg~3g

- Control mode

- Program control to achieve multi-stage temperature control; the program can be set to at least 5 stages

- Weighing system Accuracy

- 0.01mg

- Display mode

- 24Bit color, 7-inch LCD touch screen display

- atmosphere control

- Dual independent airflow control device, automatic switching of software programming

- The furnace is chilled down

- Air-cooled: 1000 ℃ -50 ℃ ≤ 13min (with water-cooled separately)

- software

- Intelligent software can automatically record TG Linear dispersion for data processing and print experimental reports

- Power Supply

- AC220V 50Hz

- Heating power

- ≤1000w

- operating software

- Data collection Frequency can be customized settings, set acquisition Frequency real-time, 2S, 5S, 10S Yes, custom

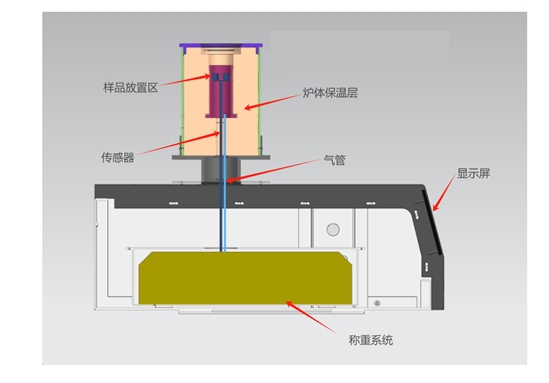

- System architecture

- Top Loading, Vertical Balancing System, No Radiation Screen Design, Optimized Airflow Condition, Less Pollution, Easy Operation

- Communication interface

- USB communication, two-way communication

- Miscellaneous

- Instrument lower machine with temperature multi-point correction, at least 3 points correction, high, medium and low temperature, no need to operate on the computer to complete, instrument with initial atmosphere, purge and emptying function, program control, before the experiment runs, the emptying time is set

Product Introduction

Thermogravimetric analysis (TG, TGA) is the observation of the mass of a sample as a function of temperature or time during the process of heating, constant temperature or cooling, with the purpose of studying the thermal stability and composition of the material. It is widely used in research and development, process optimization and quality control in various fields such as plastics, rubber, coatings, catalysts, inorganic materials, metal materials and composite materials.

Structural advantages

1. The furnace body is heated by double row winding of precious metal alloy wire, which reduces interference and is more resistant to high temperature.

2. The pallet sensor is made of precious metal alloy disc precision, which has the advantages of high temperature resistance, oxidation resistance, corrosion resistance and so on.

3. The power supply, circulating heat dissipation part and the main unit are separated, reducing the influence of heat and vibration on the microthermal balance.

4. It adopts the upper cover structure, which is easy to operate, and has an exhaust gas output port, which is convenient for expanding and connecting infrared and other equipment.

5. The main engine is used to isolate the thermal influence of the heating furnace on the chassis and the micro-heat balance.

6. The furnace body adopts double insulation, and the linearity is better

7. Imported weighing system, using ceramic rod to connect with the sample tray, can be plugged and unplugged; The sample holder can be changed according to different experiments to meet different testing needs.

Controller, software advantages

1. Imported ARM processor, sampling speed, processing speed is faster.

2. Four-way sampling AD collects TG signal and temperature T signal.

3. Heating control, different from the relay heating method on the market, adopts PID algorithm to accurately control the temperature. At the same time, it can be measured for cooling scanning

4. USB two-way communication is used between the software and the instrument, which fully realizes remote operation, and the parameter setting of the instrument and the operation stop of the instrument can be carried out through the computer software.

5. 7 inch full-color 24bit touch screen, better man-machine interface. The calibration of the TG is possible on the touch screen

Comply with industry standards

Plastics Polymer thermogravimetric method: GB/T 33047.3-2021

Education Methods for Thermal Analysis: JY/T 0589.5-2020

Determination of raw rubber content of neoprene composite rubber: SN/T 5269-2019

Thermogravimetric analysis of agricultural biomass feedstocks: NY/T 3497-2019

Determination of rubber ash: GB/T 4498.2-2017

Nanotechnology Thermogravimetric characterization of single-walled carbon nanotubes: GB/T 32868-2016

Test method for vinyl acetate content in ethylene-vinyl acetate copolymer for photovoltaic modules Thermogravimetric analysis method: GB/T 31984-2015

Test Method for Rapid Thermal Aging of Impregnated Varnish and Lacquered Cloth for Electrical Insulation: JB/T 1544-2015

Determination of the composition of vulcanized rubber and unvulcanized rubber by thermogravimetric analysis of rubber and rubber products: GB/T 14837.2-2014

Thermogravimetric analysis of oxidation temperature and ash content of carbon nanotubes: GB/T 29189-2012

Determination of starch content in starch-based plastics: QB/T 2957-2008

(Some industry standards are displayed)

- 1GB/T 45939-2025《Co-extrusion encapsulant film for photovoltaic module》

- 2GB/T 19469-2004《Determination of ignition temperature of pyrotechnic composition--DTA-TG analysis》

- 3GB/T 27762-2011《Standard test method for mass scale calibration of thermogravimetric analyzers》

- 4GB/T 27761-2011《Standard test method of mass loss and residue measurement validation of thermogravimetric analyzers》

- 5GB/T 14837.1-2014《Rubber and rubber products―Determination of the composition of vulcanizates and uncured compounds by thermogravimetry―Part 1:Butadiene, ethylene-propylene copolymer and terpolymer, isobutene-isoprene, isoprene and styrene-butadiene rubbers》

- 6GB/T 33047.1-2016《Plastics—Thermogravimetry (TG) of polymers—Part 1: General principles》

- 7GB/T 34916-2017《Nanotechnologies—Multi-walled carbon nanotubes—Determination of amorphous carbon content by thermogravimetric analysis》

- 8GB/T 35930-2018《Determination of vapor pressure of chemical products—Thermogravimetry method》

- 9GB/T 14837.3-2018《Rubber and rubber products—Determination of the composition of vulcanizates and uncured compounds by thermogravimetry—Part 3:Hydrocarbon rubbers,halogenated rubbers and polysiloxane rubbers after extraction》

- 10GB/T 33047.3-2021《Plastics—Thermogravimetry (TG) of polymers—Part 3: Determination of the activation energy using the Ozawa-Friedman plot and analysis of the reaction kinetics》

DZ-TGA103

DZ-TGA103