HT2916 Ultrasonic Coating thickness gauge Simultaneous measurement of multi-layer thickness, Non-metallic/metallic coating thickness

Factory HT2916 Multilayer Ultrasonic Thickness GaugeSPEC

Factory HT2916 Multilayer Ultrasonic Thickness GaugeDetails

Factory HT2916 Multilayer Ultrasonic Thickness GaugePacking list

- SKU

- NB049734

- Measurement principle

- ultrasound

- Measurement range

- 13~ 1000μm (epoxy resin coating), 300~ 14800μm (45 #steel)

- margin of error

- ≤ +/- ( 3% H + 3 μm) H is the Standard value

- resolution

- 1μm

- Speed of sound

- 1000~9999m/s

- Display

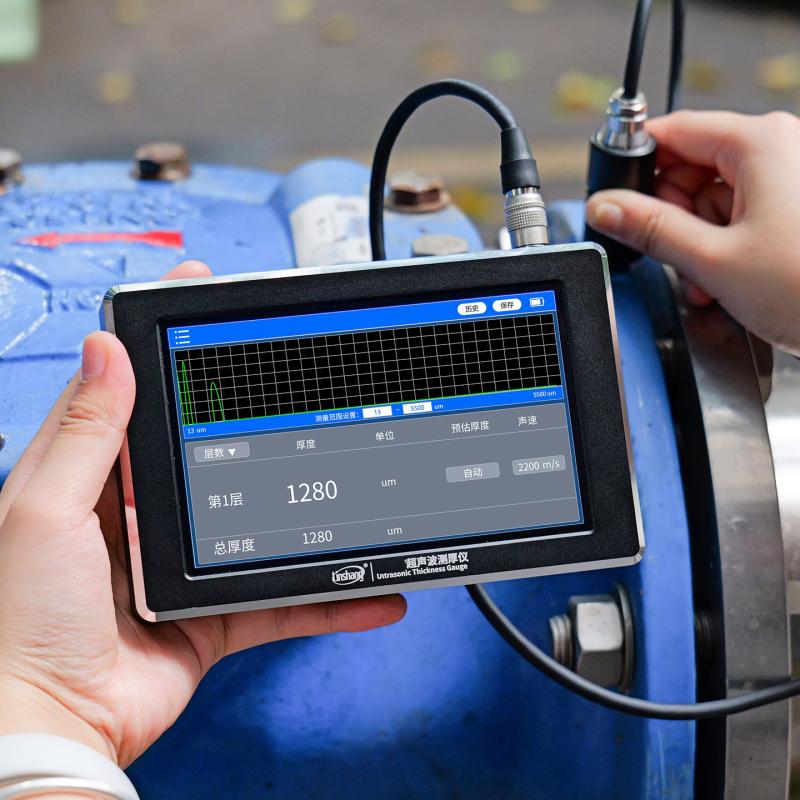

- 800 * 480 point array IPS color screen

- unit display

- μm/mil

- Minimum measurement area

- Φ6mm

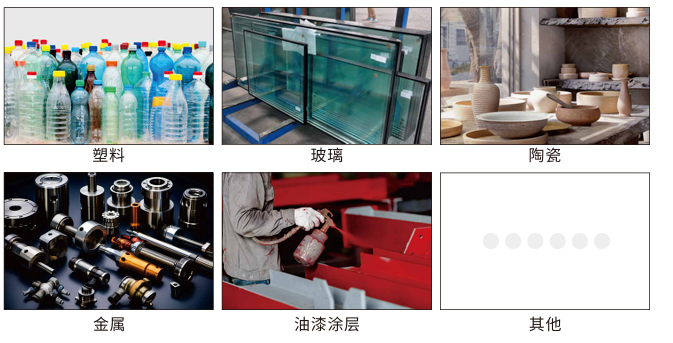

HT2916 is a handheld ultrasonic coating Thickness Gauge with pulse-reflective ultrasonic measurement principle, which is professionally used in ceramics, plastics, and glass The thickness of the surface coating of non-metallic substrates that can conduct ultrasonic waves, such as glass, and the thickness of the substrate itself, can also be measured and the thickness of the metal substrate itself.

Features:

It can measure the thickness of multiple layers of coatings or coating + substrate at the same time to meet complex inspection needs.

The instrument uses high-speed ADC data acquisition with a resolution of up to 1μm.

High-definition IPS color screen design, simple and convenient operation.

With the function of automatic gain switching, the appropriate gain can be automatically selected according to the material type and thickness.

Large measuring range: 13~1000um (epoxy resin coating), 300~14800um (45# steel).

Measurement waveform display, you can move the green cursor in the waveform display area to view the data for the rest of the waveform.

It has a range setting function, which can effectively reduce the interference echo.

It has an estimated thickness setting function to improve the accuracy of the instrument for multiple coating measurements.

Three sound velocity settings for flexible adaptation to various scenarios.

It has the function of ambient temperature compensation, and the value is stable, allowing long-term calibration.

Operating Principle

The probe emits a high-frequency ultrasonic pulse, which enters the coating through the couplant (short elapsed time, negligible), and when encountering the coating interface of different densities, a part of the ultrasonic wave will be reflected into a new ultrasonic pulse, and the other part passes through, and the new ultrasonic pulse returns to the probe, which is received by the sensor, and the propagation time of the ultrasonic wave in the coating is obtained by the instrument, and the coating thickness is calculated.

- 1Selection skills of handheld coating Thickness Gauge

- 2Principle, application and selection of traffic coatings Coating Thickness Gauge

- 3Coating Thickness Gauge working principle and common faults

- 4Nondestructive measurement Coating thickness

- 5Coating Thickness Gauge knowledge points

- 6Principle and application of digital non-contact Coating Thickness Gauge

- 7Principle, Application and Selection of Eddy current Coating Thickness Gauge

- 8Determination method of coating dry-film thickness

- 9Principle, application and selection of stainless steel paints Coating Thickness Gauge

- 10Coating Thickness Gauge Precautions for use

HT2916

HT2916