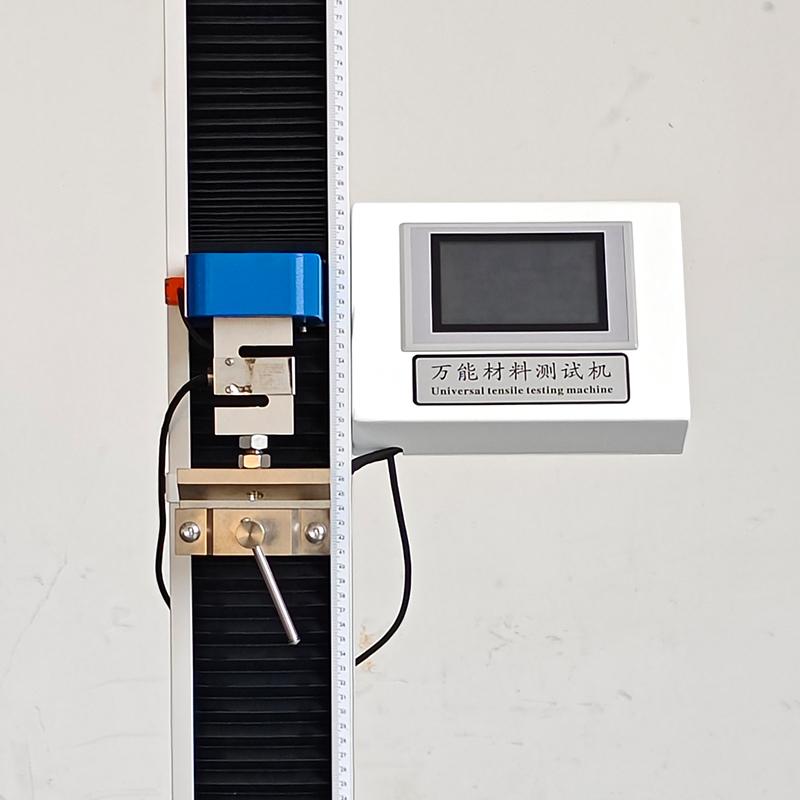

Lugong STX500 Digital Display Single Arm Tensile Tester Microcomputer-controlled Electronic Universal Testing Machine 500N

LUGONG STX500 Digital single arm Tensile TesterSPEC

LUGONG STX500 Digital single arm Tensile TesterDetails

LUGONG STX500 Digital single arm Tensile TesterPacking list

- SKU

- NB049986

- maximum test force

- 500N

- Force Precision

- Level 1

- Measurement range

- 2%--100%FS

- Force value indication Accuracy

- Better than indication +/- 1%

- Force resolution

- 1/3000

- Measurement Accuracy of beam displacement

- Resolution higher than 0.01mm

- Test speed range

- 0.1 - 500mm/min, stepless speed regulation

- Safety protection device

- Mechanical limit protection and software overload protection

- Test space

- 650Mm (can be customized according to user request)

- Operating Environment

- Room temperature - 35 ℃, Relative Humidity does not exceed 80%

- Dimension

- 470×470×1210mm

- Weight

- Approx. 90 kg

- Power supply for the whole machine

- Single phase, 220V +/- 10%, 50Hz; 400W

Product Introduction

The digital display single-arm micro-controlled electronic universal testing machine is a new generation of microcomputer-controlled electronic universal testing machine specially designed for universities and scientific research institutes. The design of the main engine and auxiliary devices draws on the international advanced technology, with beautiful appearance, convenient operation, stable and reliable performance. The high-precision stepper motor and driver are used to drive the precision ball drive screw and guide rod to load after deceleration, and complete a variety of mechanical property tests such as tensile, compression, bending, and shear of the sample, which has a wide and accurate loading speed and force measurement range, and has high accuracy and sensitivity for the measurement and control of load, deformation and displacement. It is suitable for tensile, peeling and tearing performance testing of plastic films, composite films, flexible packaging materials, adhesives, adhesive tapes, self-adhesives, rubber, paper and other products, and is a reliable testing equipment for scientific research institutions, colleges and universities, industrial and mining enterprises, technical supervision, commodity inspection and arbitration departments.

host

The main machine adopts a high-rigidity single-arm structure, which has a beautiful appearance;

Using high-precision ball screw, the transmission is efficient and stable

The transmission part is driven by arc tooth synchronous belt, and there is no gap in both directions during the transmission process

High-precision stepper motor and drive system are used to ensure stable transmission and accurate control

The clamp is specially designed, the clamping is firm, the operation is convenient, and there is no jaw slippage

The special process ensures the coaxiality of the testing machine, and eliminates the influence of irregular specimens on the sensor

Control system

This includes load measurement, displacement measurement and deformation measurement systems

The large LCD screen displays the control parameters and measurement results in real time

It has functions such as overload protection

- 1What are the common stripping test applications and test standards?

- 2Common problems and solutions in tensile testing

- 3Tensile machine application in various industries

- 4What are the application industries of Tensile Testing Machines?

- 5What are the common tensile test applications and standards?

- 6How many driving methods are there for Tensile Testing Machines?

- 7Factors Affecting the Performance and Accuracy of Tensile Testing Machines

- 8Technical analysis of key parameters of Tensile machine: Scientific selection from force measurement accuracy to Power system

- 9Tensile machine purchasing guide [dry version]

- 10Classification of Tensile Testing Machines

STX500

STX500