HuiNuo HN-AY80 Gravure Ink Proofer color scheme Special numerical control LCD display

-

HuiNuo CP150 gravure plate Proofer Gravure ink printing machine printability instrument$ 3987.00SE

HuiNuo CP150 gravure plate Proofer Gravure ink printing machine printability instrument$ 3987.00SE -

MODERNER AYDJ Ink Proofer (Gravure) with D version printability instrument

MODERNER AYDJ Ink Proofer (Gravure) with D version printability instrument -

MODERNER AYDJ Ink Proofer (Gravure Printing) with C1 version of the sample 150 lines Printability Tester

MODERNER AYDJ Ink Proofer (Gravure Printing) with C1 version of the sample 150 lines Printability Tester -

MODERNER AYDJ inks printing proofing machine (gravure) with B1 version Water-based ink

MODERNER AYDJ inks printing proofing machine (gravure) with B1 version Water-based ink -

CHINA Gravure Color Display Machine NBC-130$ 5741.00SE

CHINA Gravure Color Display Machine NBC-130$ 5741.00SE

HuiNuo HN-AY80 Ink ProoferSPEC

HuiNuo HN-AY80 Ink ProoferDetails

HuiNuo HN-AY80 Ink ProoferPacking list

- SKU

- NB050105

- Power supply Voltage

- 220V±10%

- Host Weight

- About 90Kg

- Rotation speed

- 300 rpm (adjustable)

- Swirl/spin specified number of turns

- 1/2 or can be set arbitrarily

- Swirling/spinning Accuracy

- 0.1 degree

- LCD content

- Rotation speed, lap number accumulation and other technical indicators

- EPDM (silicone roller/polyurethane, etc./optional) Hardness

- 65 Degrees

- Pattern standard film width

- 80mm

- board width

- 120mm

- Packaging Dimensions

- 650*550*450mm

- Operating Conditions

- 10 ℃ -35 ℃ range, Relative Humidity not more than 80%

Product Introduction

The ink proofing machine adopts LCD display, CNC motor drive, control system integrated structure, synchronous belt driven version of the roller spindle mechanism, all control parameters and measurement data can be displayed and adjusted in real time on the LCD screen, and has reliable accurate repeat positioning and other functions.

Huinuo HN-AY gravure ink proofing machine is a CNC equipment designed for ink color matching and proofing, which solves the cost and efficiency pain points of the industry. It drives a high-precision motor (rotation accuracy of 0.1 degrees) through the LCD numerical control system to achieve one-click operation and real-time monitoring of parameters, significantly reducing 90% of the ink waste of traditional machine proofing, and efficiently digesting the old ink in stock ("turning waste into treasure"). The equipment supports the detection of hue, concentration and gloss of multi-color inks, and can output Lab value reports with spectroscopic densitometers to achieve data-based color management; It can also predict the characteristics of dry and wet ink color change, wear resistance, weather resistance and so on. It is widely adapted to gravure printing processes such as plastic film, printing iron, and decorative paper, and can show the spot color printing effect for customers in 5-10 minutes, helping ink factories, printing factories and plate making enterprises to reduce residual ink inventory, shorten the proofing cycle, and improve customer approval efficiency.

Product value

Realize the three functions of color matching, proofing and finalization.

1. It mainly solves the big problem of ink color waste.

2. Use the mixed ratio of new and old inks to display the color block, color sample, and 5%~95% color ratio.

3. Fully solve and dispose of a large amount of inventory of old ink, and turn "waste" into treasure.

4. Drip ink to overcome the "embarrassing place" of traditional machine proofing.

Product characteristics:

1. The substrates are widely used, suitable for gravure printing, packaging and ink enterprises.

2. Multi-color ink detection: It can detect the hue, gloss, and color concentration of ink.

3. For customers to approve spot colors before pressing: simple color strips can be made for customers to approve or purchase inspection before press.

4. Detect the degree of discoloration of dry and wet inks: display the required spot color ink color strips, and you can know the hue after the spot color is dried after natural drying.

5. When used with the ink quantifier, the amount of spot color ink can be predicted, and the loss of residual ink and warehouse accumulation can be greatly reduced.

6. Data management: cooperate with the spectrometric densitizer for color inspection, and measure the data report (Lab value) of the color bar.

7. With relevant instruments, the wear resistance, fading, transferability, light resistance, heat resistance and other characteristics of ink can be predicted.

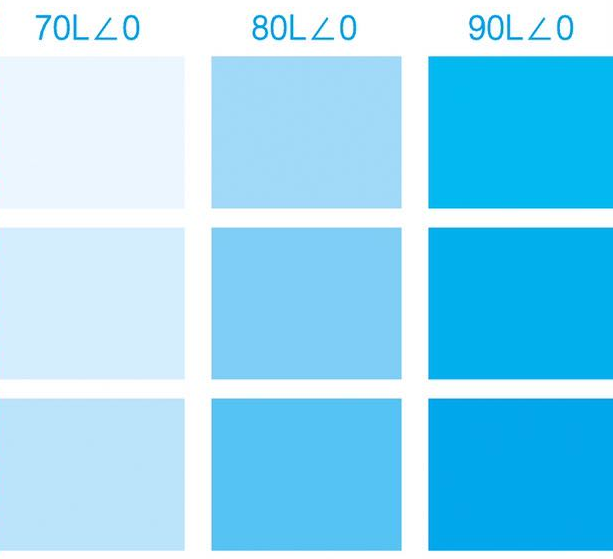

Proofing effect

Scope of application

1. Applicable industries Plastic film printing, decorative paper gravure, printing and dyeing, printing iron, and the gravure printing process involved.

2. Suitable for gravure printing With the cooperation of special proofing machines and color software, the residual ink inventory of the printing company can be greatly reduced and cost saved.

3. It is suitable for ink manufacturers, inks or agents.

A. Data management, with spectrometer for color inspection, measurement of color bar data report.

B. Cooperate with relevant instruments to test the wear resistance, color fading, transferability, light resistance, heat resistance and other characteristics of the ink.

4. Applicable plate making factory: analog printing machine to make spot color samples.

A. The company's production process curve is simple and convenient, and the process personnel can quickly display the color individually without the cooperation of the concave sample workshop.

B. The manuscript designer can also show the color to the on-site customer within 5-10 minutes, and the customer can see the final printed color on the finished product at the beginning of the design.

Color/spot color contrast

1. The number of color blocks of the corresponding response of the proofing line is compared with the color of the standard sample.

2. Take the color block of the corresponding depth, measure and compare it with the standard sample with a Spectrophotometer , and then further finely adjust it. When the color proximity rate reaches 95% similarity, the sample can be put on the printing press for trial printing.

3. Multi-stage color blocks, which are convenient for comparing different network cable color matching and gradient effects.

HN-AY80

HN-AY80