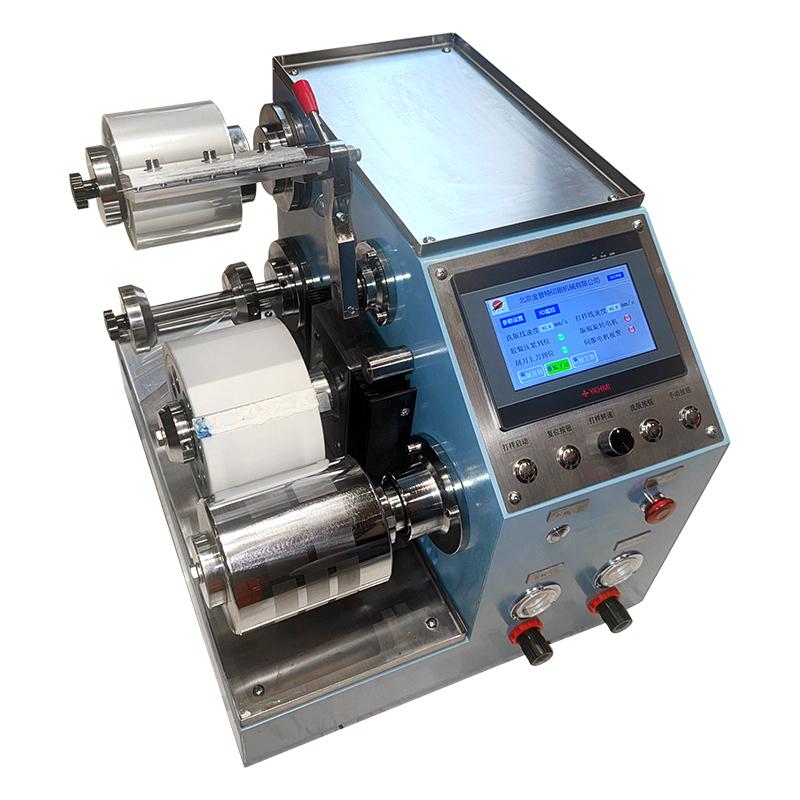

HuiNuo HN-AY150 smart Ink Proofer servo numerical control motor, double station discharge

-

HuiNuo CP150 gravure plate Proofer Gravure ink printing machine printability instrument$ 3987.00SE

HuiNuo CP150 gravure plate Proofer Gravure ink printing machine printability instrument$ 3987.00SE -

MODERNER AYDJ Ink Proofer (Gravure) with D version printability instrument

MODERNER AYDJ Ink Proofer (Gravure) with D version printability instrument -

MODERNER AYDJ Ink Proofer (Gravure Printing) with C1 version of the sample 150 lines Printability Tester

MODERNER AYDJ Ink Proofer (Gravure Printing) with C1 version of the sample 150 lines Printability Tester -

MODERNER AYDJ inks printing proofing machine (gravure) with B1 version Water-based ink

MODERNER AYDJ inks printing proofing machine (gravure) with B1 version Water-based ink -

CHINA Gravure Color Display Machine NBC-130$ 5741.00SE

CHINA Gravure Color Display Machine NBC-130$ 5741.00SE

HuiNuo HN-AY150 Smart Ink ProoferSPEC

HuiNuo HN-AY150 Smart Ink ProoferDetails

HuiNuo HN-AY150 Smart Ink ProoferPacking list

- SKU

- NB050106

- Voltage

- 220V +/- 10% (foreign 110V +/- 10% + conversion plug)

- Rotation speed

- 300 rpm (allows reset +)

- Swirl/spin specified number of turns

- 1/2 or can be set arbitrarily

- Swirling/spinning Accuracy

- 0.1 ° (degrees)

- LCD content

- Rotation speed, lap number accumulation and other technical indicators

- Host Weight

- About 150Kg (export standard wooden box)

- Embossing roller

- Standard EPDM (silicone roller/polyurethane, etc./optional), Hardness 75 ° (universal Hardness of rubber roller selected by printing factory)

- Proofer box size

- 750x600x500mm

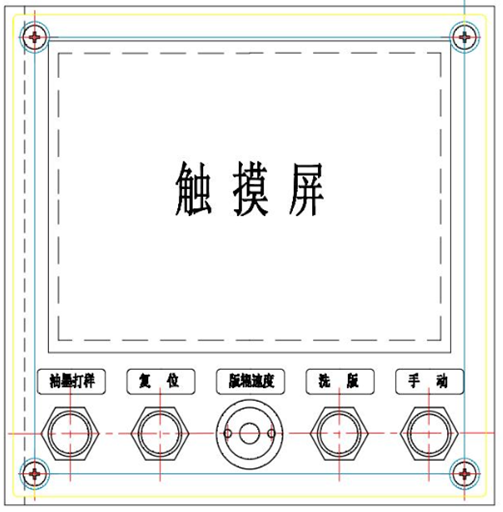

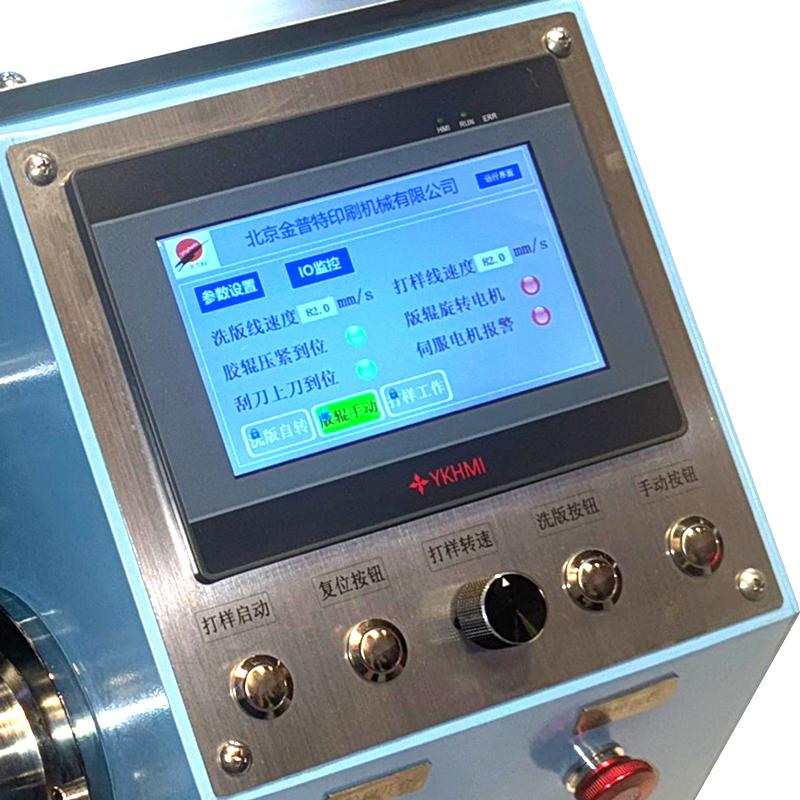

- Panel function settings

- emergency stop, proofing speed gear adjustable, plate roller cleaning, manual, reset, rubber roller opening and closing button

- Printing plate width

- 150mm

Product Introduction

Huinuo HN-AYpro intelligent ink proofing machine is upgraded with double-station discharge + servo CNC motor as the core upgrade to achieve industrial-grade precision proofing. Equipped with a fully intelligent LCD system, real-time adjustment of rotation speed (300 rpm adjustable), number of turns (0.1° accuracy) and other parameters; The double unwinding constant tension design ensures the stability of proofing, and with the ink scraper imported from Switzerland and the customized high-precision plate roller, it significantly extends the life of consumables and improves the scraping efficiency. A new centralized exhaust gas recovery system (optional) has been added to discharge solvent in a directional manner to ensure safe and environmentally friendly operation, while the 75° hardness rubber roller accurately matches the needs of the printing plant. One machine integrates the whole process of proofing, detection and prediction, and synchronizes color display in 5 minutes with dual stations, helping ink factories and printing companies reduce costs by 60% of waste ink loss, and complete customer signature in 10 minutes, redefining the new standard of intelligent proofing.

The intelligent proofing machine adopts fully intelligent LCD display, servo CNC motor drive, servo control system integrated structure, synchronous belt driven version roller spindle mechanism, all control parameters and measurement data can be displayed and adjusted in real time on the LCD screen, and has reliable accurate repeat positioning and other functions.

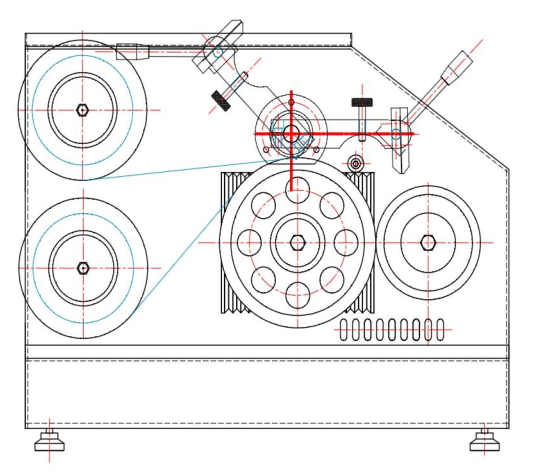

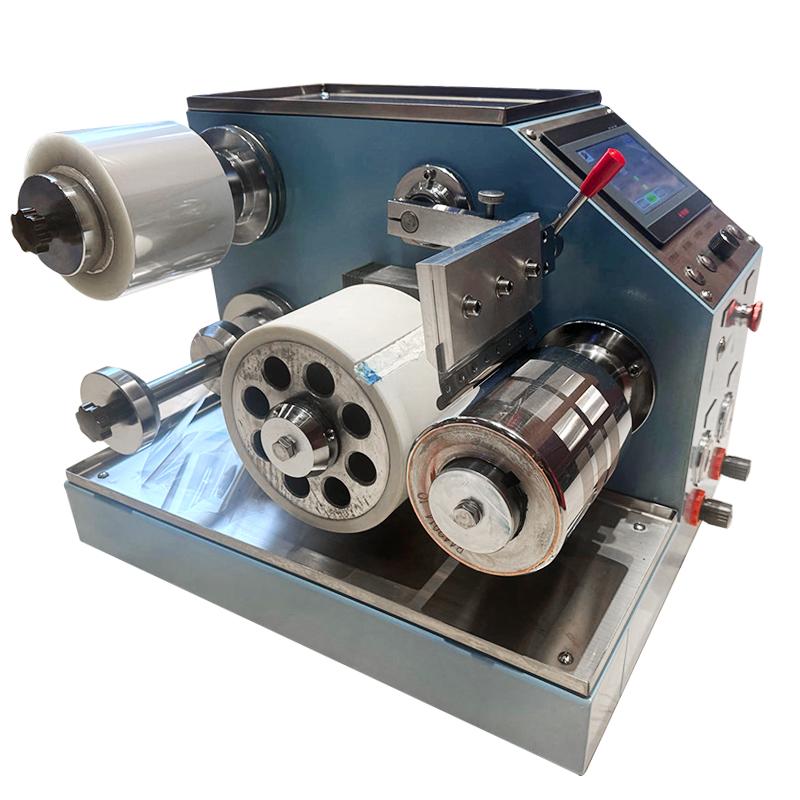

Exterior structure drawing

Operating Conditions of the proofer

1. In the range of room temperature 10°C-35°C, the Relative Humidity is not greater than 80%.

2. Install and calibrate the levelness correctly on a solid foundation or workbench.

3. Use in a vibration-free environment.

4. There is no corrosive medium around.

5. The fluctuation range of the 220V power supply Voltage should not exceed ±10% of the rated Voltage.

6. The power supply needs to have strict grounding protection.

Introduction to the institution

The intelligent proofing machine is composed of a main machine, an electrical controller and accessories, as shown in the attached figure.

1. Host part

The main machine is divided into five parts: double unwinding part, press roller part, ink scraping part, and plate roller partExhaust gas centralized collection and discharge part.

A. The unwinding part uses a combination of friction plates and springs to form an effective constant tension to ensure theThe tension of the certificate is adjustable and maintained.

B. The pressure roller part uses silicone rubber roller, so that the life of the rubber roller is effectively extended.

C. The ink scraping part adopts aluminum alloy cleats, Swiss imported combination tool clips, and Swiss ZOC-LLThe combination of long-life small gold knives reduces the loss of the ink scraper and improves the assembly and disassembly of the ink scraperConvenient function.

D. The plate roller part adopts customized high-precision plate roller (made by Shanghai Plate Making Company), specializedThe layout design of the industry highlights the professional level and craftsmanship of the enterprise.

E. The centralized storage part of exhaust gas (optional), the use of high-speed fan to effectively proofThe solvent is effectively stored and discharged, and can be docked with the exhaust pipe.

2. Electrical control part

The electrical part of the intelligent proofing machine adopts the combination of CNC operation servo dynamic control machine and servo CNC motor to form a set of system with high speed, large torque and high rotation accuracy.

HN-AY150

HN-AY150