HZAOC LYS-500 Condensate Test Chamber automatic intelligent constant temperature and humidity volume 500L

hzaoc LYS-500 Condensate Test ChamberSPEC

hzaoc LYS-500 Condensate Test ChamberDetails

hzaoc LYS-500 Condensate Test ChamberPacking list

- SKU

- NB050395

- Constant climate state test technical parameters

- /

- temperature range

- Room temperature~ 60 ℃

- Test area temperature error range

- ±2℃

- Temperature fluctuation

- ±1.0℃

- Heating rate

- 0~2.0 ℃ per minute

- Humidification method

- Static water heating and humidification (humidity approximately 100%)

- Overheating protection method

- Primary PT100 temperature transducer false alarm protection, alarm at the same time. Secondary Thermocouple over temperature stop running, alarm protection at the same time

- Condensation ventilated test environment

- /

- temperature range

- Room temperature~ 28 ° C; (environment temperature higher than 28 ° C need to turn on the air conditioner)

- Test area temperature error range

- ±2℃

- Ventilating method

- Circulation fan for external circulation ventilating

- humidity range

- Less than 100% RH

- Chill down saturated test environment

- /

- temperature range

- Room temperature~ 28 ° C; (environment temperature higher than 28 ° C need to turn on the air conditioner)

- Test area temperature error range

- ±2℃

- Humidification method

- Atomization humidification method

- parameter

- /

- laboratory Volume

- 500L

- Outer box mm

- 1450 × 1450 × 800 (approx.)

- Studio

- D *W*H :1000×1000×500mm

- Power Supply

- AC 220V 50HZ 2.0KW

- Door size

- 500 * 600Mm (approx.)

- structure

- /

- Humidification device

- Ultrasonic atomization tower, the Controller supports intermittent humidification function to maintain a high humidity value in the box when doing AT experiments.

- Heating method

- The heating tubes of this machine are all made of titanium alloy heating tubes, which are heated by hidden water. During the test, the humidity in the box can also be increased to the required level, which can not only greatly improve the heating efficiency, but also directly reduce the energy consumption by about 50%. Lay a "Hot Plate" on the heating tube; it can make the heat more evenly and continuously dissipate, which not only looks more beautiful, but also can effectively improve the temperature uniformity in the test chamber.

- control part

- ① Programmable control, can save historical records and data export; ② Classify and preset according to national standards, select the corresponding test standard, and start with one click; support automatic water intake (test chamber and saturation bucket), and automatically protect against dry burning due to water shortage.

- shell

- The whole machine is made of flame retardant PP material. Compared with traditional PVC material, PP material has the advantages of high temperature resistance, easy cleaning, and firm welding. The safety of flame retardant materials is guaranteed.

- Supports sample Weight

- Within 30KG, it is recommended to place it scattered.

- V/O rack

- 1 set

- Operation manual

- 1 serving

- Plastic rust-proof bucket

- 1 (5L Capacity)

- accessories

- /

- Inner and outer box

- 8Mm grade A PP sheet (high temperature resistance, easy to clean, strong welding)

- box cover

- PP plate with transparent Viewing Window, the same as the box material

- Smart Touch Screen Controller

- MCGS7-inch touch screen (IPx34 waterproof rating)

- Atomization device

- Atomization humidification

- Over temperature protection

- Sensitivity plus or minus 3 ℃

- Water level switch

- High temperature resistant PP float

- Heating tube

- High-speed titanium alloy U-shaped heating tube

- relay

- 2 digits 2 passes

- Solid State Relay

- Strong anti-interference ability

- Solenoid valve

- fluororubber anti-corrosion

- pressure gauge

- anti-corrosion

- Sensors

- PT100

- Pneumatic system

- With small filtrating device

- AC contactor

- 1810

Product Overview:

The automatic condensation testing machine has the characteristics of standardization and intelligence, and is mainly in testing compared with the traditional salt spray testing machine

A lot of improvements have been made in terms of accuracy and test automation to reduce the errors caused by human intervention, especially for the atomization nozzle, which has formed the characteristics of fine atomization particles and uniform atomization, and at the same time, all use wall-mounted spray towers, saving a lot of space.

The purpose of this test is to explain the reaction produced and to provide an understanding of the anti-corrosion defects of the test subject under humid environmental and climatic conditions. The climatic conditions used for the test cannot be used as a basis for predicting the service life of coatings in actual Operating Environments.

Usage environment

1. Ambient temperature: 5°C~ 28°C

2. Humidity of the Operating Environment: ≤85%RH;

3. Place it against the outdoor wall (as shown in the picture on the right)

4. Testing and storage of flammable, explosive and volatile substance samples;

5. Test method: DIN_EN_ISO_6270-2 condensate climate test test method.

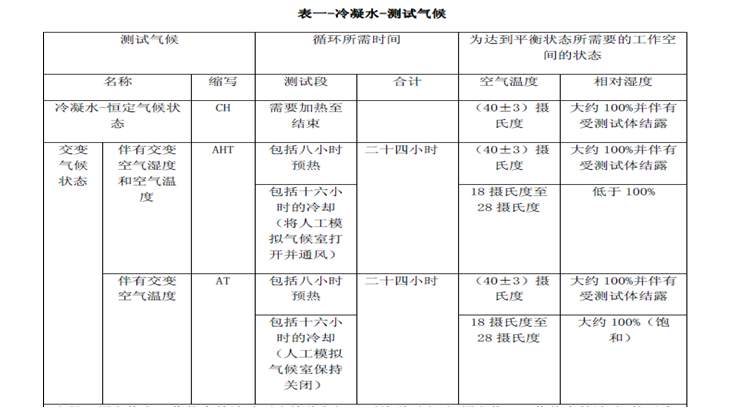

Test the climate

control panel

LYS-500

LYS-500