HuiNuo TM3000Pro/25 Automatic Film Applicator bar drawdown blade Coater ECA 92 * 92cm servo motor

HuiNuo TM3000pro/25 Automatic Film ApplicatorSPEC

HuiNuo TM3000pro/25 Automatic Film ApplicatorDetails

HuiNuo TM3000pro/25 Automatic Film ApplicatorPacking list

- SKU

- NB050488

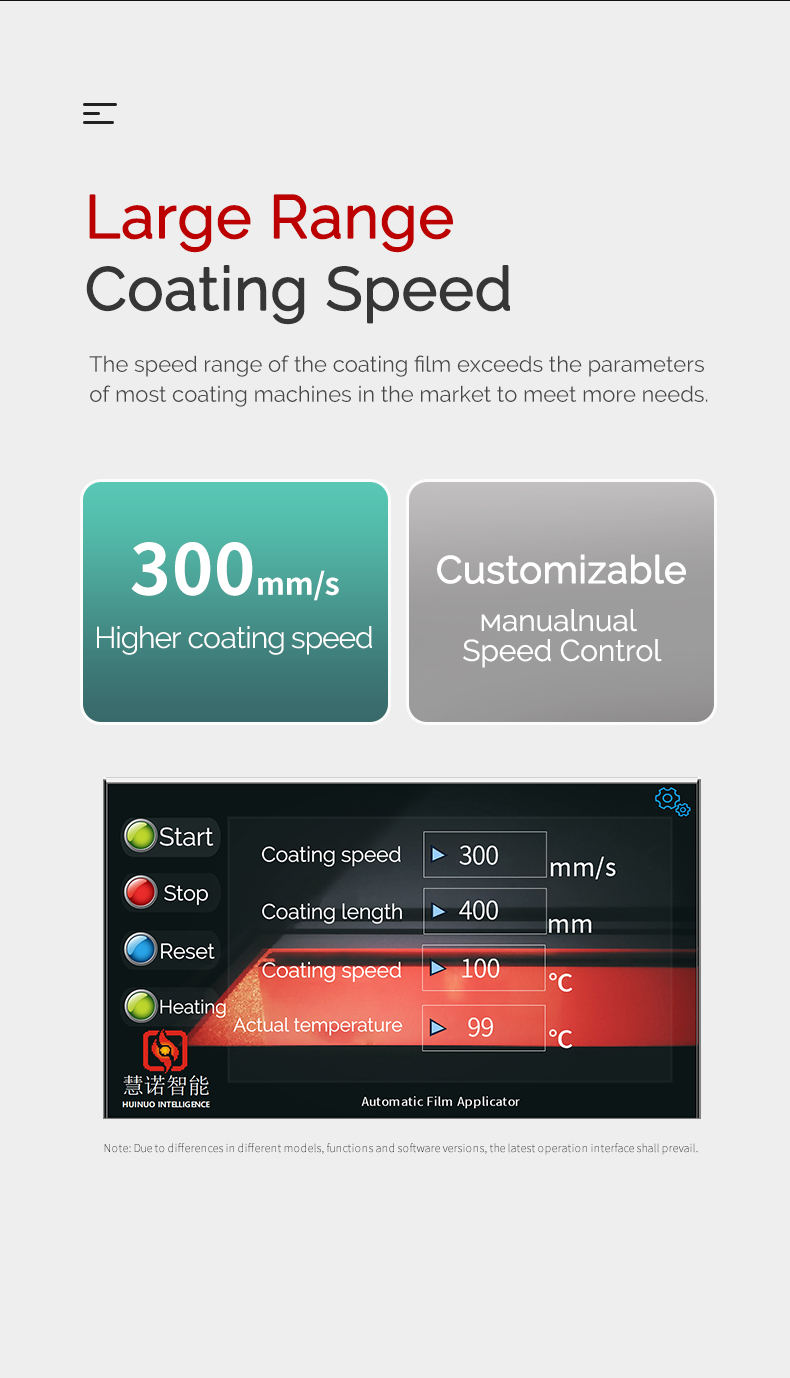

- Coating Speed

- Single-direction linear speed 1-80mm/s

- Wire speed Accuracy

- ±1%

- Spreader Itinerary

- 0~450*0~450

- Precision of stroke length

- ±0.03mm

- R axis swirl/spin speed

- 0-180rpm

- R axis rotation Accuracy

- About 0.5 arc minutes

- Sample material

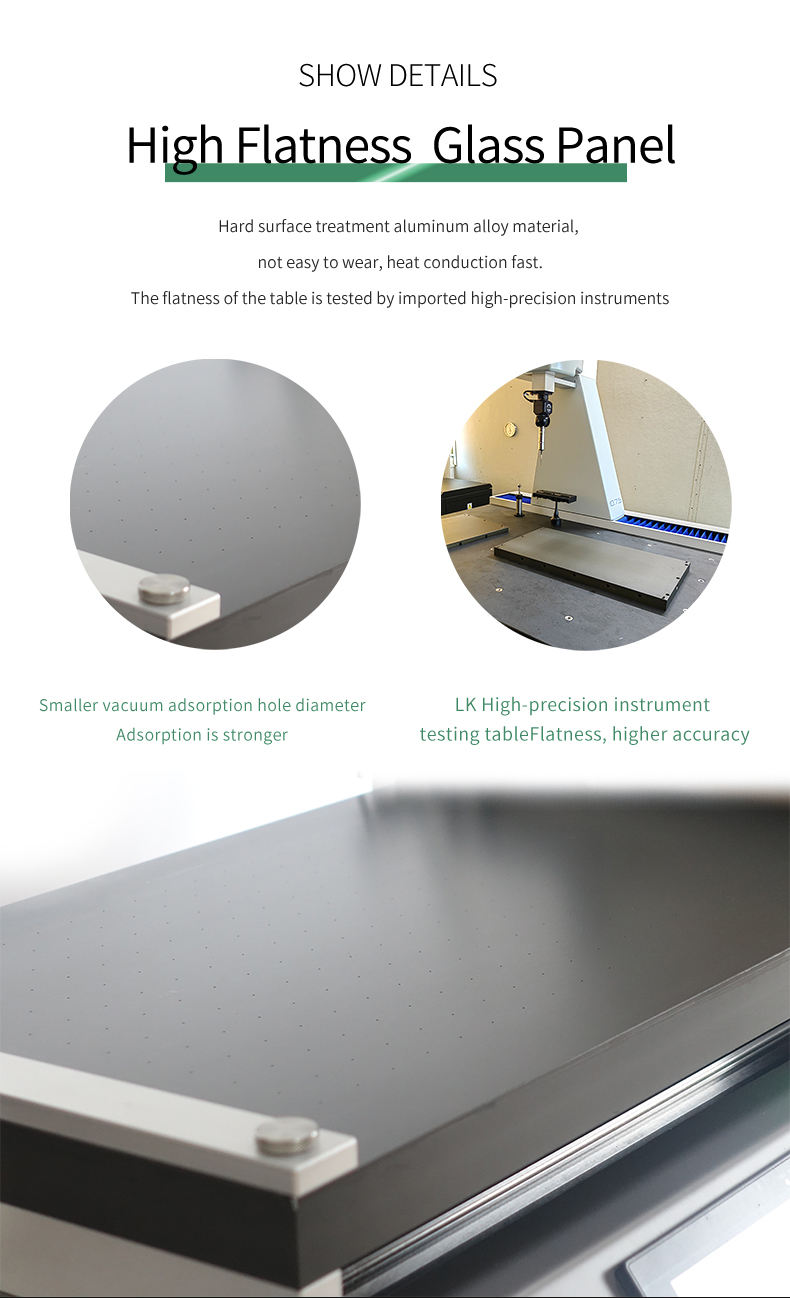

- 000 grade marble

- sample flatness

- +/- 5 microns

- Sample size

- 920*920mm

- Drawdown blade straightness

- +/- 3 microns

- Scraping Accuracy

- +/- 3 microns (with leveling mechanism)

- Test substrate thickness

- 0-40mm

- Drawdown blade height adjustable range (film thickness)

- 0-10mm

- Maximum film substrate area

- Φ450mm

- Host Power Supply

- AC 220V 50Hz 16. Power consumption 1200W

- Drive motor

- Servo motor

- Display

- 480 * 272 pixel 5 inch TFT display

- language

- Chinese

- Control mode

- Screen touch control

- core function

- 1. XY direction movable coating table. 2.360 swirl/spin adjustable drawdown blade. 3. XYR each axis traverse speed, distance adjustable.

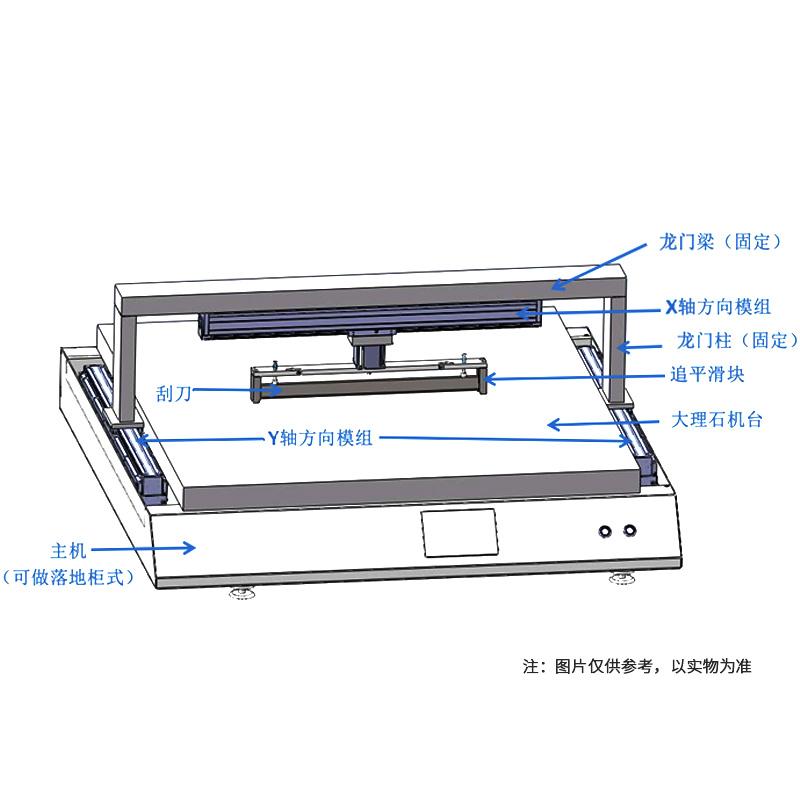

- subsystem composition

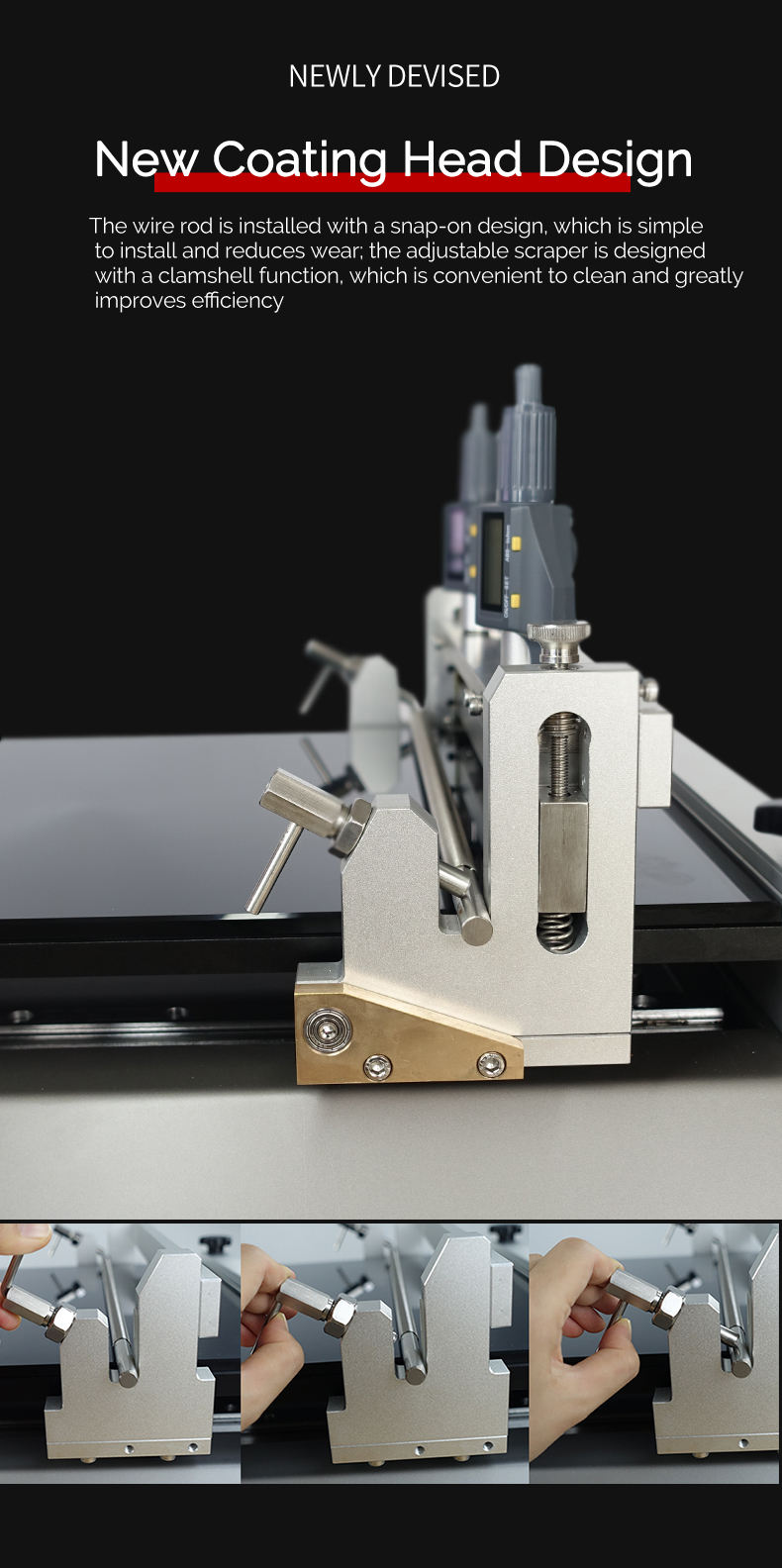

- 1. Motion system: XY direction: servo motor + screw + linear guide. R axis: servo motor + swirl/spinning disc 2. Adjustable drawdown blade system: Digital Micrometer, spiral scale differential head, leveling slider, die steel drawdown blade and aluminum alloy tool holder 3. Control system: PLC + touch screen, support parameter preset.

- Overall size (estimated)

- Host length × width × height: 1200mm × 1200mm × 700mm.

- Space Allocation

- Upper layer: X axis + R axis + adjustable drawdown blade. Middle layer: marble film platform. Lower layer: Y motion mechanism + PLC + touch screen + power module.

- human-machine interaction

- 5-Inch touchscreen for easy parameter setting

Product Overview:

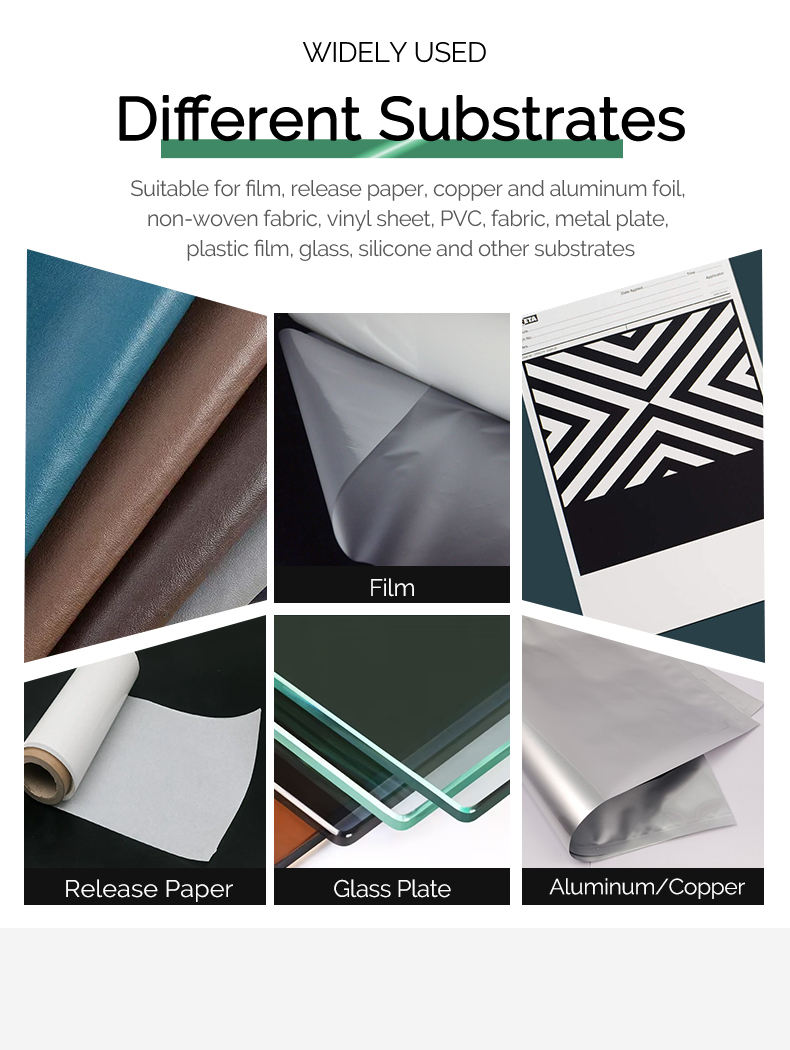

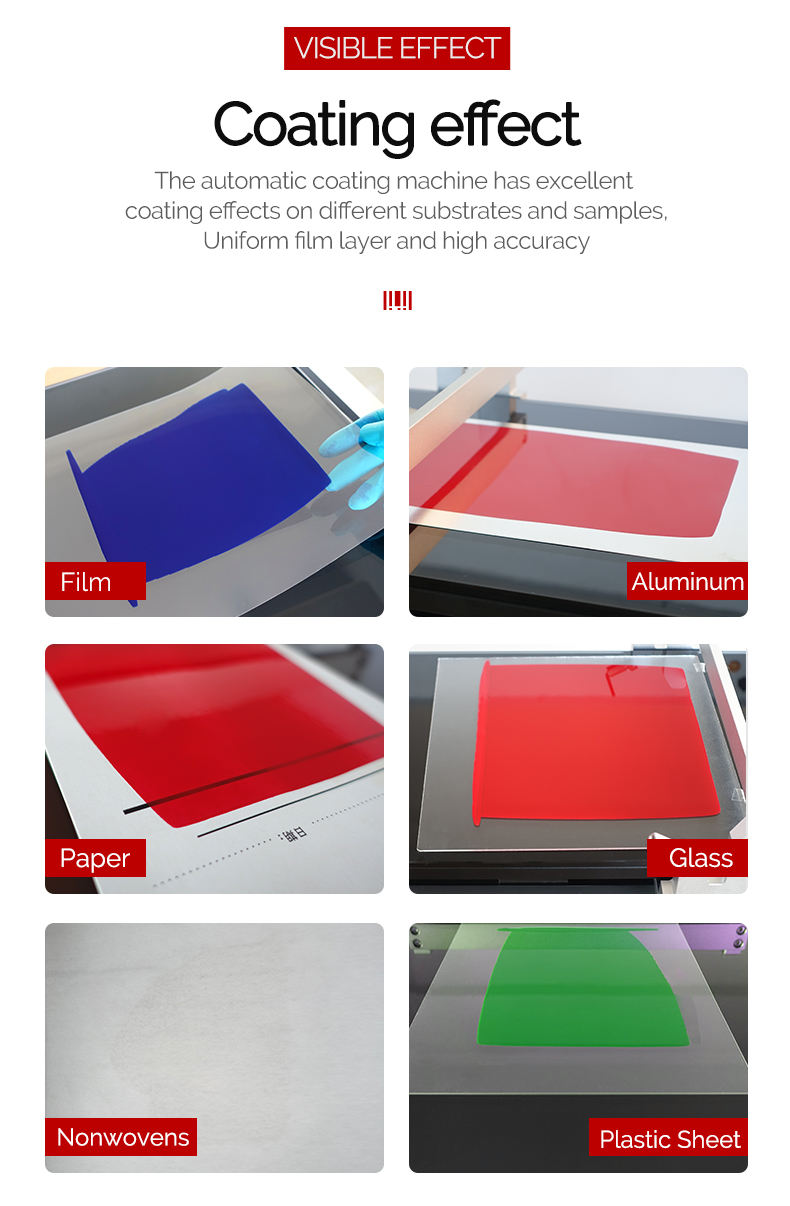

Automatic film coating machine is a device used to coat film in the laboratory, replacing manual film coating, automating the film coating, and improving the accuracy and efficiency of film coating. The working principle of the experimental automatic film coating machine is to evenly coat the sample on the substrate by controlling the coating head and coating parameters, forming the desired film.

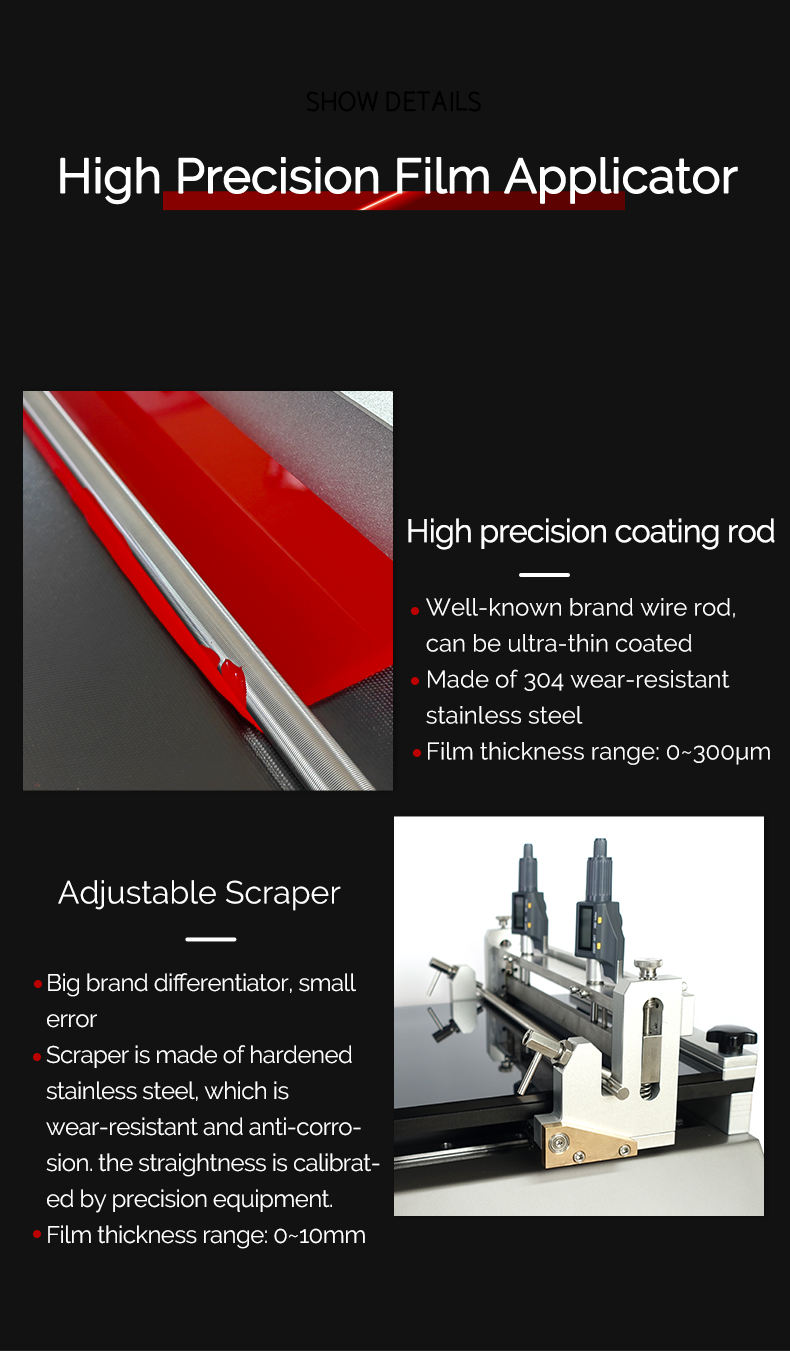

This coating machine is a wire rod scraper coating machine, with two functions of wire rod coating and scraper coating, the new wire rod installation method and clamshell scraper head greatly improve the coating efficiency, easy to clean, with speed control and coating length adjustment function, suitable for high-precision automatic coating of film in the laboratory, in university research institutes, new materials, lithium batteries, glue, resin and other laboratories for film proofing.

Product Use:

The film coating machine is suitable for coating and sample coating of coatings, inks, paints, pastes, lithium batteries, pressure-sensitive adhesives, resins, glues, polymer materials, pharmaceuticals, etc., and can be scraped on glass, cardboard, and fabrics.

Features

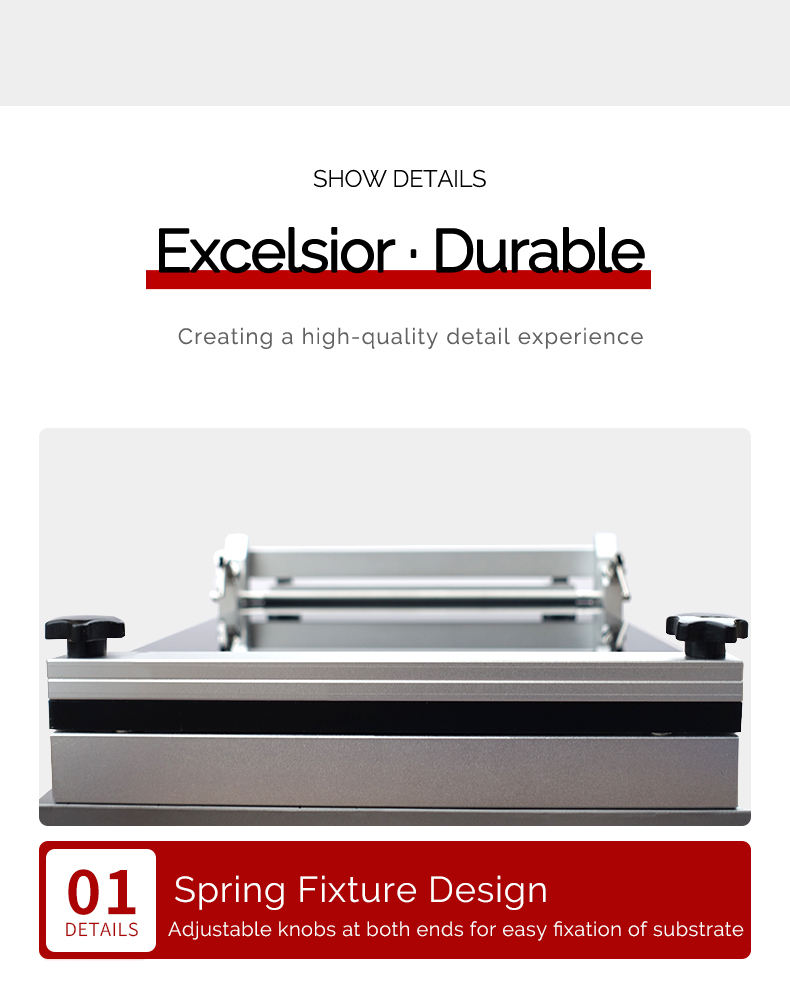

1) High flatness hard aluminum alloy bottom plate, scratch and scratch resistance

2) Big brand differential adjuster, high film thickness control accuracy

3) Clamshell scraper coating head, easy to clean

4) Equipped with high-precision Film Applicator, the original imported wire rod coating film is uniform and high accuracy

5) Touch screen control panel, easy to operate

6) The coating length and coating speed can be adjusted freely

TM3000pro/25

TM3000pro/25