Specifications

| Performance parameters | indicator value |

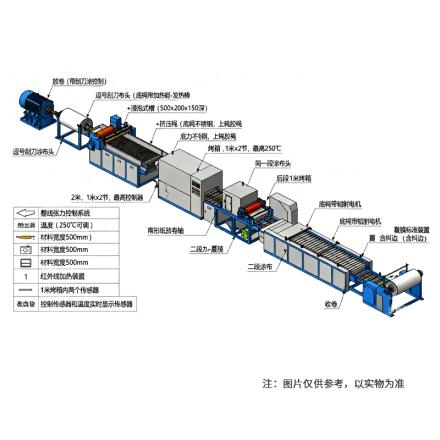

| Spreader process | Unwinding → scraping → soaking → double roll extrusion → drying → scraping → drying → film laminating → edge correction → winding |

| Coating Method | Scratch coating + soaking |

| Cutting head type | Comma drawdown blade (bottom roller with heating function - heating rod) |

| Cutting head material | stainless steel |

| Maximum material width | 560 mm |

| Effective application width | 500 mm (adjustable width baffle) |

| Film Accuracy | +/- 0.005mm (stepless speed regulation) |

| Spreader wet thickness range | 0.1 ~ 3mm |

| percentile | digital display |

| resolution | 0.001mm |

| Spreader thickness control | manual adjustment |

| Running speed range | 0.1 ~ 10 m/min |

| Bath size | 500Mm (L) x 200mm (W) x 150mm (D) (Internal Dimensions) |

| Bath material | SUS304 or SUS316 stainless steel, ensure compatibility with slurry, anti-corrosion (main material) |

| Extrusion roller material | Upper roller (rubber roller material) + bottom roller (stainless steel material) |

| Extrusion roller structure | Formed bottom film laminating layer, release paper put reel to install tension Controller |

| Total length of drying zone | 3 meters (1 meter/section x 3 sections) |

| Drying Temperature range | Room temperature~ 250 ° C (each section is independently controllable) |

| Drying zone structure | One drying area: 2 sections, 1 meter each, for pre-curing/drying after the bottom layer Spreader Two drying areas: 1 section, 1 meter each, for final curing/drying after the surface layer Spreader |

| Temperature control Accuracy | +/- 3% (in steady state) |

| exhaust | Air Volume: total exhaust air Volume ≥ 800 m ³/h |

| interface | Provides 3 DN150 flange ports (1 per oven) |

| Tension range of the whole machine | 2~ 50 kg (adjustable) |

| Tension control Accuracy | +/- 5% setting value |

| maximum outer diameter of winding | φ 500 mm (tentative) |

| unwinding method | Inflatable shaft unwinding |

| winding method | Inflatable shaft winding |

| Outer diameter of winding air expansion shaft | 3-Inch expansion shaft, load-bearing 50KG |

| Control mode | PLC + touch screen |

| Human Machine Interface | Color touch screen |

| Motor type | Servo motor |

| main Power Supply | Three-phase Five-wire 380VAC/50Hz, Total Power Approx. 75kW |

| Control Power Supply | Single phase 220VAC/50Hz |

| compressed air | Pressure: 0.6~ 0.8 MPa (clean, drying) |

| consumption | Average 0.3 Nm ³/min, peak 0.8 Nm ³/min |

| interface | G1/2 "quick Connector |

| Total Installed Power | Approximately 75 kW (peak estimate) |

| Equipment Dimensions | Approx. L x W x H Technologies 11000 x 1800 x 2200 mm (including operating space) |

| Total Weight of equipment | Approx. 3500 kg |

Packing list

machine x1, manual x1, certificate x1, warranty card x1

After-sales instructions

Warranty days: 365 days

[Note] For after-sales services outside the Chinese mainland, if the instrument requires repair, the shipping and possible associated taxes shall be borne by the sender. Generation address of the manual: http://en.nbchao.com/p/50526/Specification.html , which is only used by users who purchase commodities from the NBCHAO.