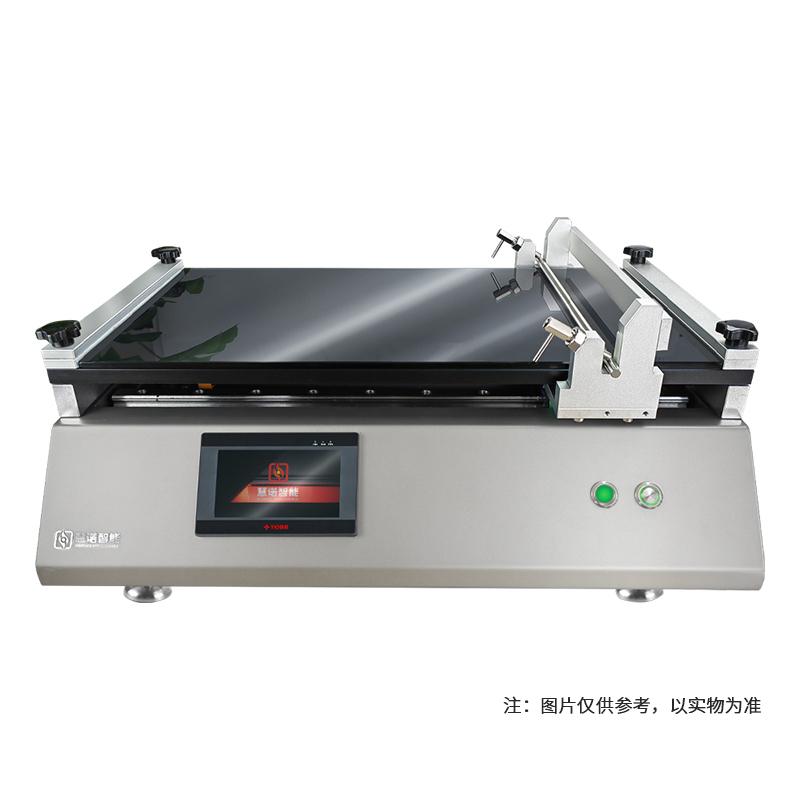

HuiNuo TM1000Pro/500g Automatic Film Applicator bar coater High Accuracy film applicator

HuiNuo TM1000pro/500g Automatic Film ApplicatorSPEC

HuiNuo TM1000pro/500g Automatic Film ApplicatorDetails

HuiNuo TM1000pro/500g Automatic Film ApplicatorPacking list

- SKU

- NB050661

- coating method

- Bar Spreader

- coating method

- Bar Spreader

- coating speed

- 1~ 300Mm/s stepless speed regulation (can be customized)

- coating speed

- 1~ 300Mm/s stepless speed regulation (can be customized)

- Substrate clamping method

- fixture

- Substrate clamping method

- fixture

- Coating table material

- Aluminum alloy/Glass table (if the specified material is confirmed with customer service)

- Coating table material

- Aluminum alloy/Glass table (if the specified material is confirmed with customer service)

- Coating table size

- 600*300mm

- Coating table size

- 600*300mm

- effective coating area

- 400 * 300Mm (can be customized)

- effective coating area

- 400 * 300Mm (can be customized)

- Film Film thickness

- Controlled by bar with High Accuracy import bar

- Film Film thickness

- Controlled by bar with High Accuracy import bar

- meyer rod coating accuracy

- ±0.001mm

- meyer rod coating accuracy

- ±0.001mm

- Load at both ends of the bar

- Each 500g weight

- Load at both ends of the bar

- Each 500g weight

- Drive motor

- Servo motor

- Drive motor

- Servo motor

- power

- 600w

- power

- 600w

- operating language

- Chinese (can be customized in English)

- operating language

- Chinese (can be customized in English)

- display screen

- Color LCD Touchscreen

- display screen

- Color LCD Touchscreen

- Host power supply

- 220V/50HZ (can be customized 110V/60HZ)

- Host power supply

- 220V/50HZ (can be customized 110V/60HZ)

- dimensions

- 658*438*205mm

- dimensions

- 658*438*205mm

- weight

- 39.7kg

- weight

- 39.7kg

- optional feature

- Drawdown blade, heating, Vacuum chuck

- optional feature

- Drawdown blade, heating, Vacuum chuck

Product Overview:

Automatic film coating machine is a device used to coat film in the laboratory, replacing manual film coating, automating the film coating, and improving the accuracy and efficiency of film coating. The working principle of the experimental automatic film coating machine is to evenly coat the sample on the substrate by controlling the coating head and coating parameters, forming the desired film.

This film coating machine is a basic wire rod coating machine, using a new wire rod installation method, with speed control and coating length adjustment functions, suitable for high-precision automatic coating in the laboratory, in university research institutes, new materials, lithium battery and other laboratories for film proofing.

Product Use:

It is suitable for coatings, inks, paints, pastes, lithium batteries, polymer materials, pharmaceuticals and other coating film samples, and can be scraped on glass, cardboard, cloth, metal plates, plastic sheets.

Product features:

1) Ultra-flat glass bottom plate for 3D printing platform, high flatness, gold crystal original sheet, heat resistance 600°C, scratch resistance, scratch resistance;

2) Equipped with high-precision film applicator, the original imported wire rod coating film uniformly and high precision;

3) Touch screen control panel, easy to operate;

4) The coating length and coating speed can be adjusted freely, and the coating speed is up to 300mm/s;

5) Simple snap-on wire rod groove, simple loading and unloading, to avoid wire rod wear.

TM1000pro/500g

TM1000pro/500g