HuiNuo SZQ-100 450/500/550/700μm 4-sided Applicator Film Applicator +/- 2μm accuracy 100mm Spreader width

HuiNuo SZQ-100 450/500/550/700μm 4-sided ApplicatorSPEC

HuiNuo SZQ-100 450/500/550/700μm 4-sided ApplicatorDetails

HuiNuo SZQ-100 450/500/550/700μm 4-sided ApplicatorPacking list

- SKU

- NB050677

- type

- 4-sided

- wet film thickness

- 450/500/550/700μm

- Spreader Width

- 100mm

- accuracy

- ±2μm

- material

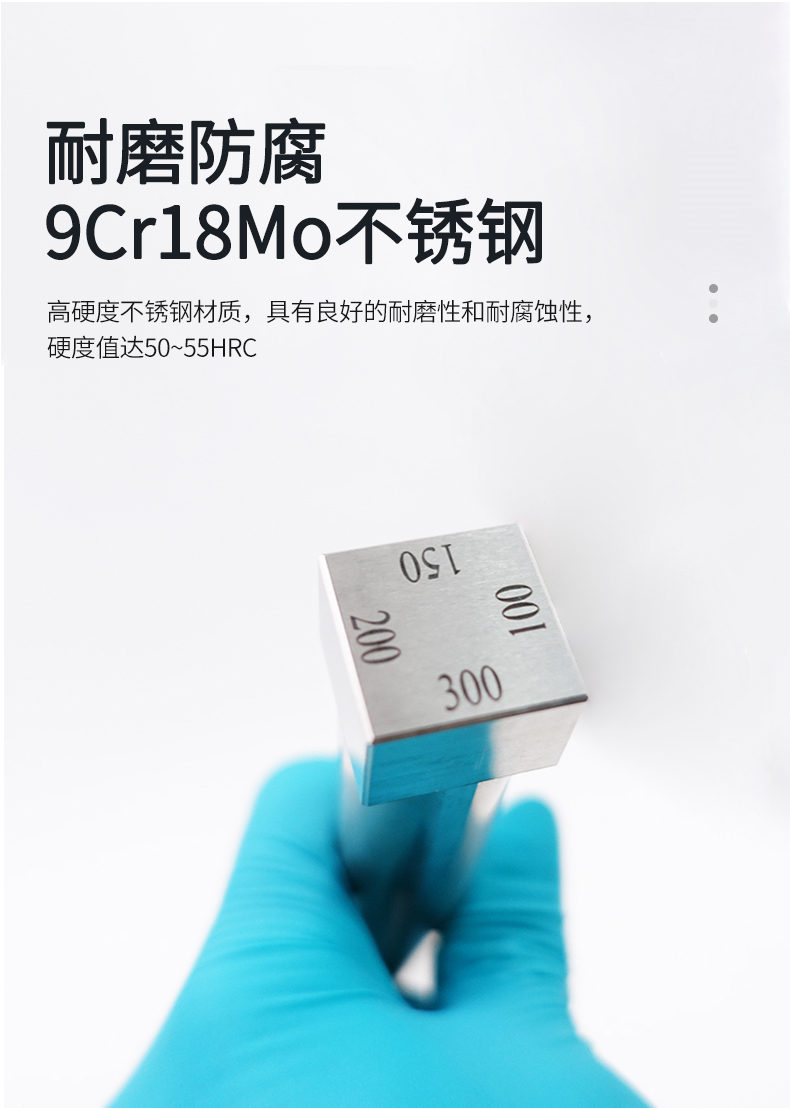

- 9Cr18Mo stainless steel

Product Introduction

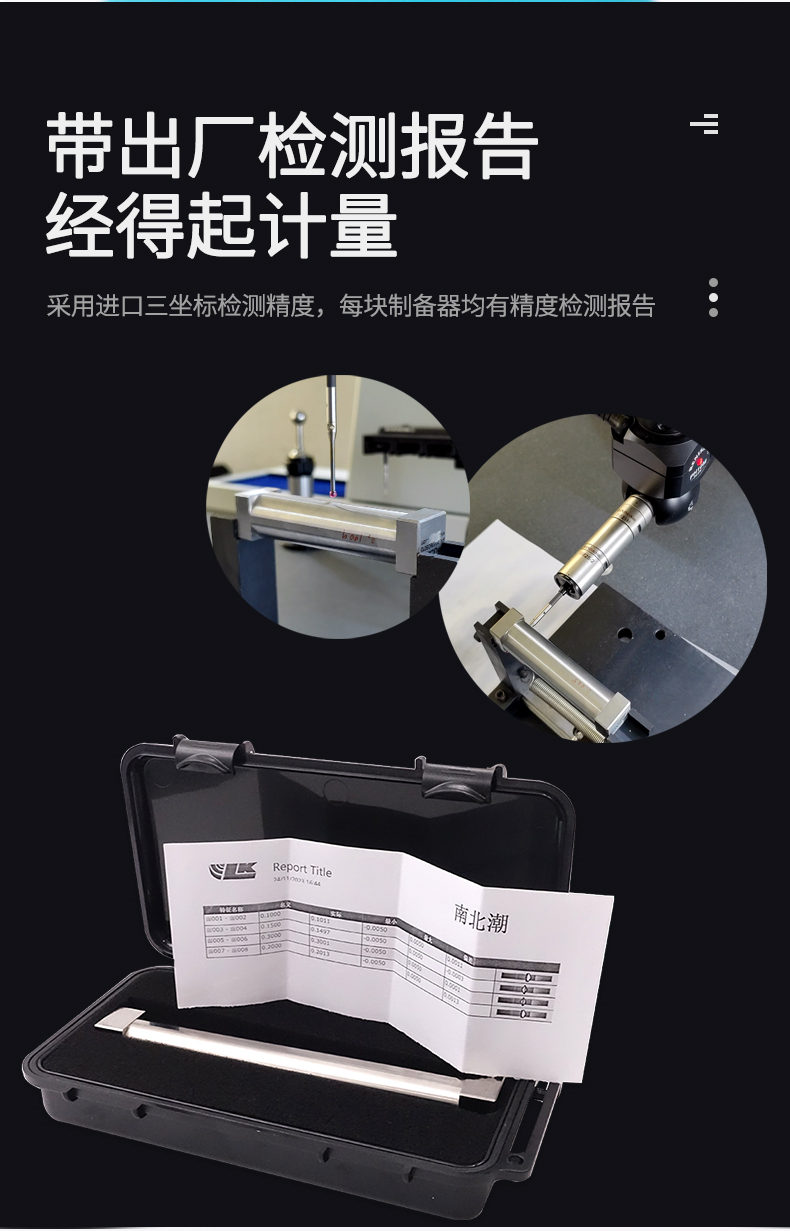

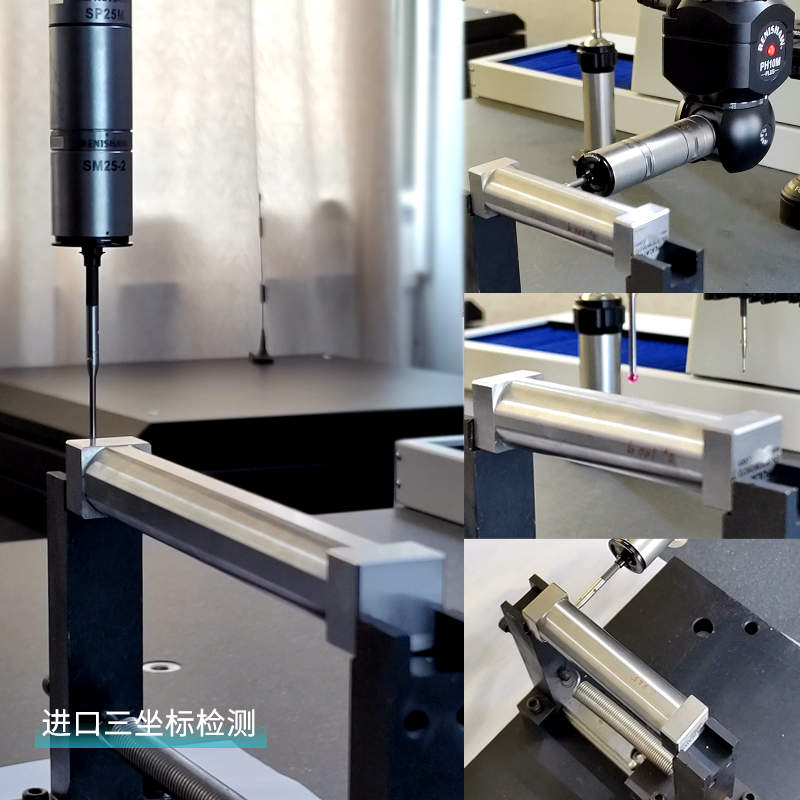

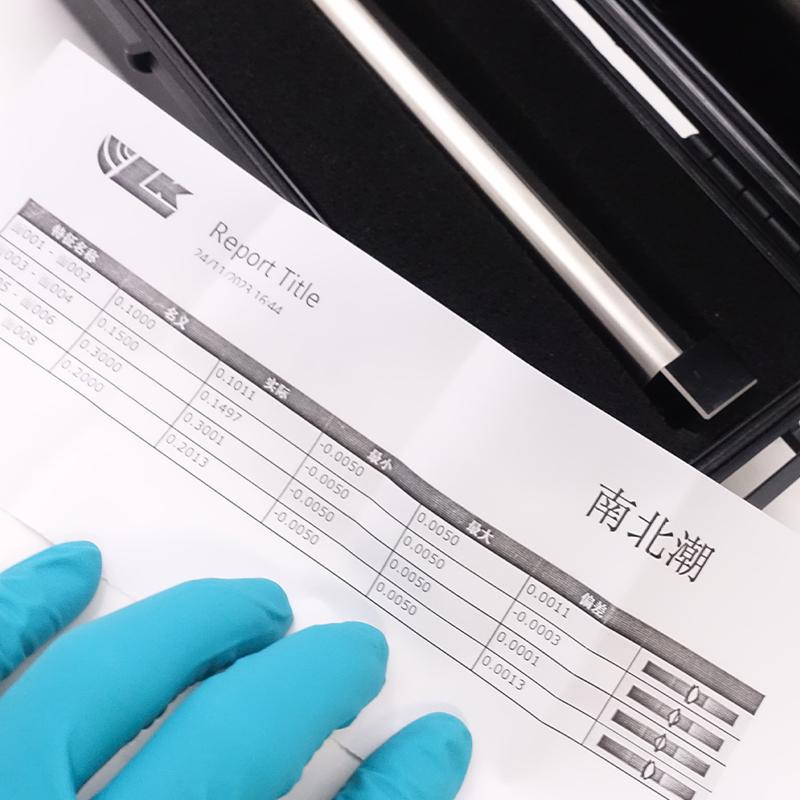

The four-sided applicator is an experimental coating device with an accuracy of ±2 microns, with two coating widths of 80 and 160mm, and is made of high-carbon-chromium wear-resistant stainless steel, which has good corrosion resistance. The wet film preparation machine will be tested for accuracy before leaving the factory, using imported three-coordinate testing, and with a factory testing data report, which can withstand measurement. SZQ four-sided film applicator is suitable for sample film proofing in resins, coatings, glues, new materials, polymer materials, and other fields. Support non-standard customization. It can also be equipped with laboratory automatic coating machine for automatic coating.

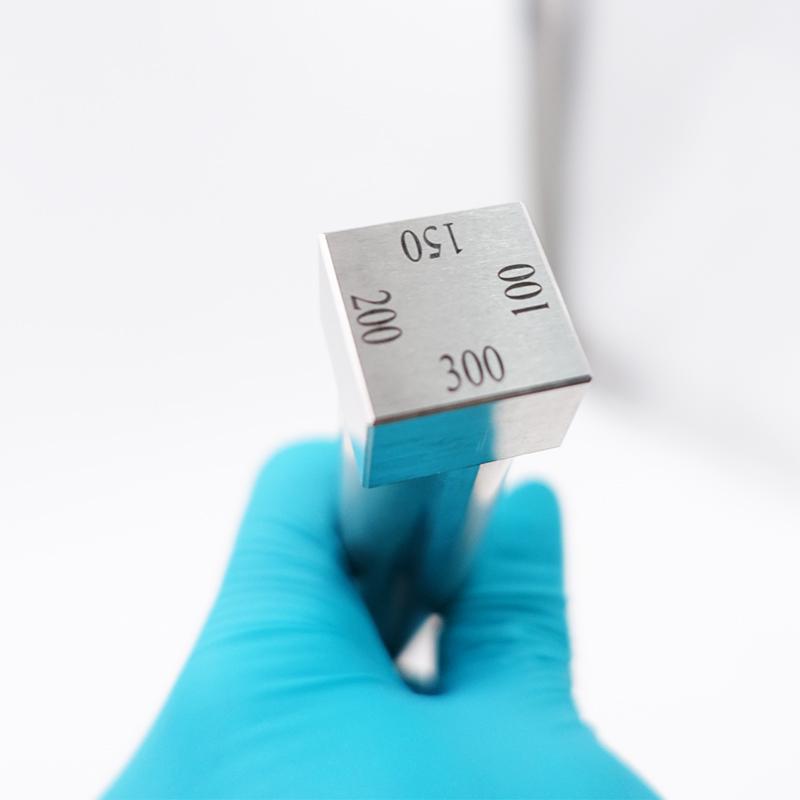

SZQ-100 450/500/550/700μm has a coating thickness of 450μm, 500μm, 550μm, and 700μm, and a coating width of 100mm, making it an extended four-sided prepper.

Product features:

1. 9Cr18Mo high-hardness stainless steel, with good wear resistance and corrosion resistance, hardness value up to 50~55HRC.

2. The accuracy is up to ±2μm to ensure the accuracy of the experiment

3. The surface is smooth, the style is diverse, the application range is wide, and customized specifications are supported

4. Adopt imported three-coordinate testing accuracy, bring factory test report, and stand up to measurement

Preparer series parameter table

| name | Specification mm | Wet film thickness μm |

| Single-sided prep | The total length is 80, and the coating width is 50 and 75 | 50、75、100、125、150、175、200 |

| Duplex prep | Total length 100, coating width 80 | 25、50、75、100、150、175、200、300、400 |

| Frame preparer | Total length 90, coating width 80 | 30、50、60、90、120、150、200 |

| Eight-sided preparer | Total length 90, coating width 68 | 50、75、100、125、150、175、200 |

| Eight-sided preparer | Total length 100, coating width 80 | |

| Square preparer | 25x25, coating width 16 | 37、50、75、100 |

| Square preparer | 50x50, coating width 41 | 50、100 |

| Standard four-sided preparer | Total length 100, coating width 80 | All specifications and sizes support non-standard customization |

| Extended four-sided preparer | Total length 190, coating width 160 |

SZQ-100 450/500/550/700μm

SZQ-100 450/500/550/700μm