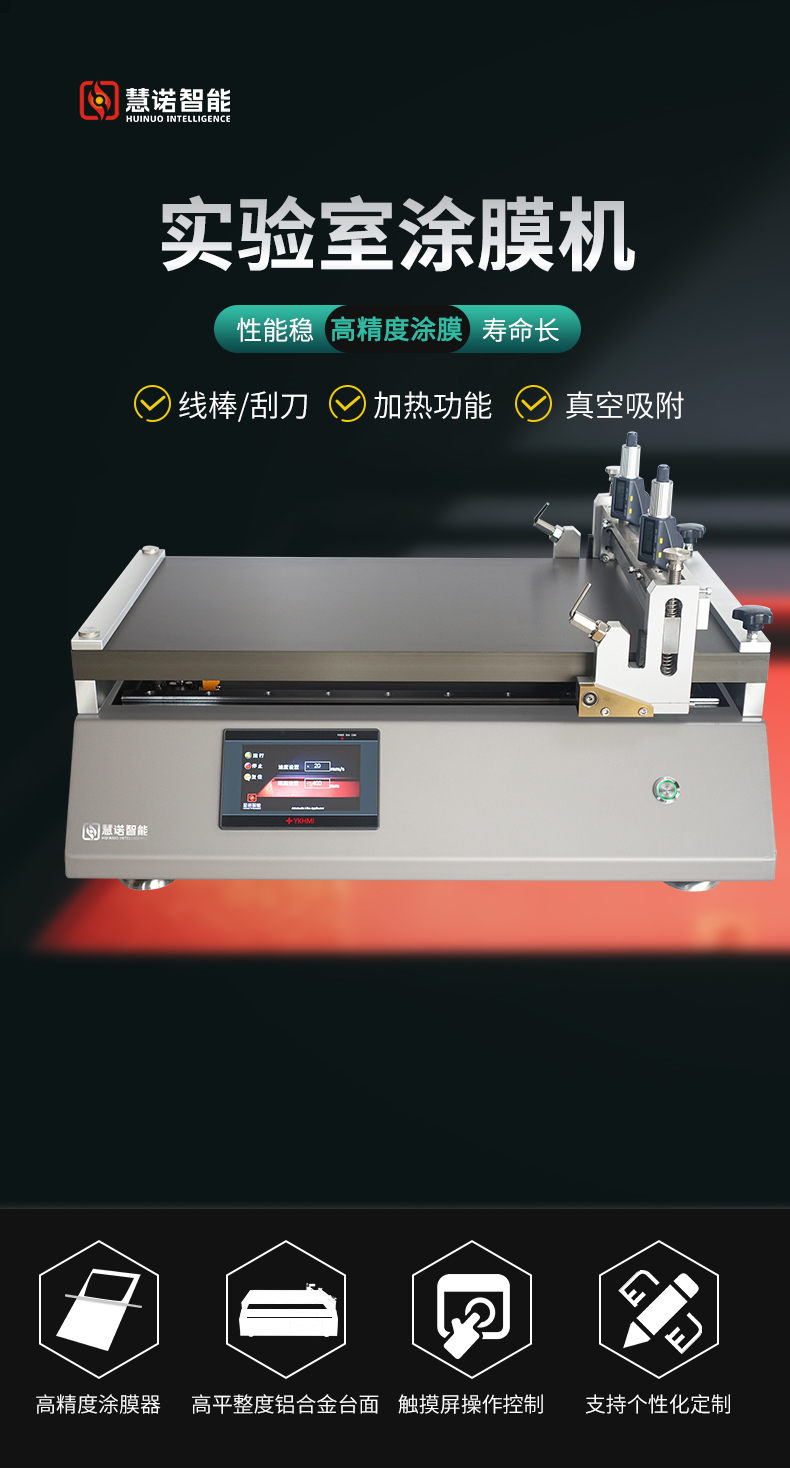

HuiNuo TM1300AF/03 Automatic Film Applicator bar type heating Vacuum chuck coater Size 50 * 30cm

HuiNuo TM1300AF/03 Automatic Film ApplicatorSPEC

HuiNuo TM1300AF/03 Automatic Film ApplicatorDetails

HuiNuo TM1300AF/03 Automatic Film ApplicatorPacking list

- SKU

- NB050688

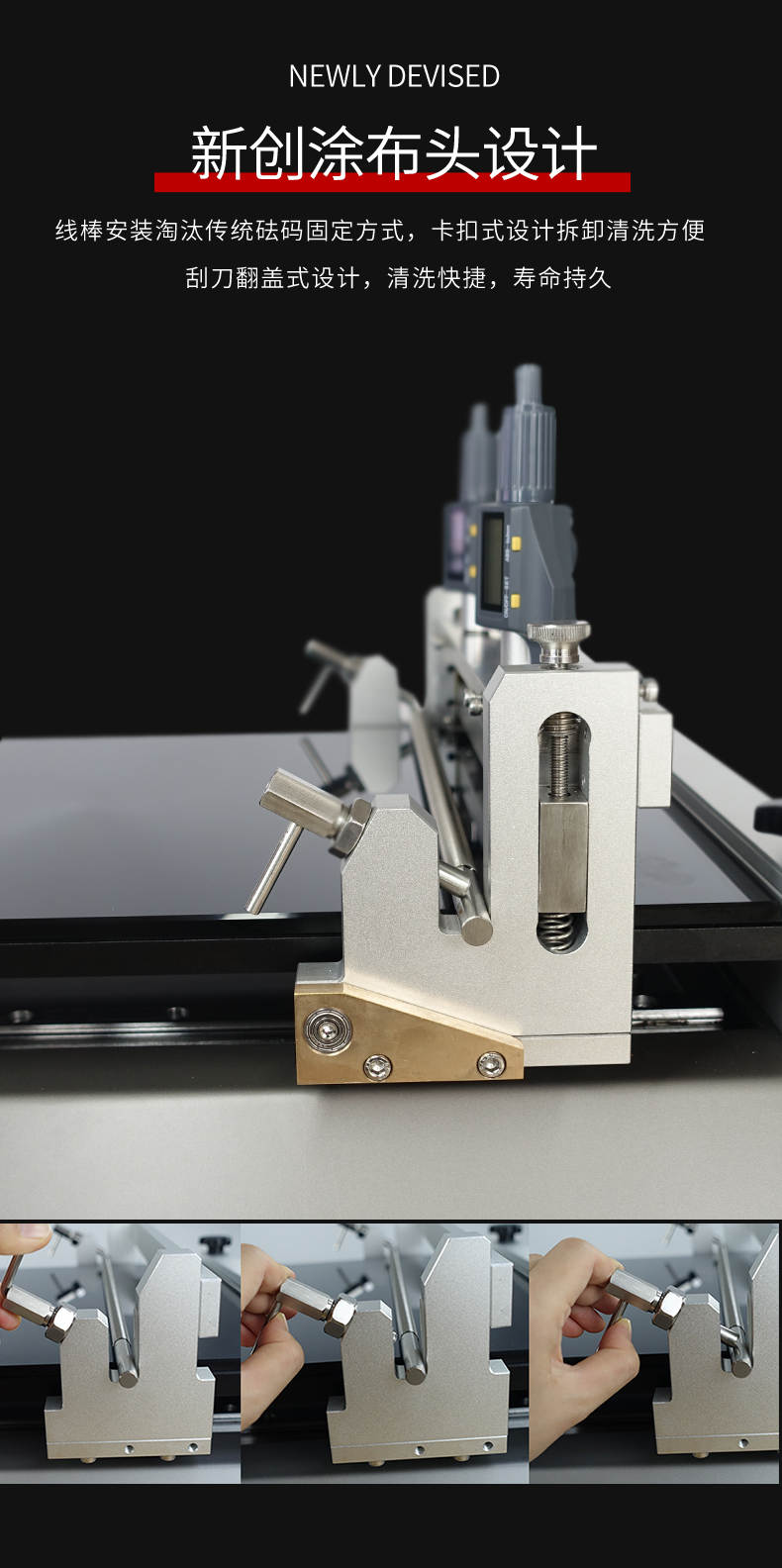

- coating method

- Bar Spreader

- coating speed

- 1~ 300Mm/s stepless speed regulation (can be customized)

- Substrate clamping method

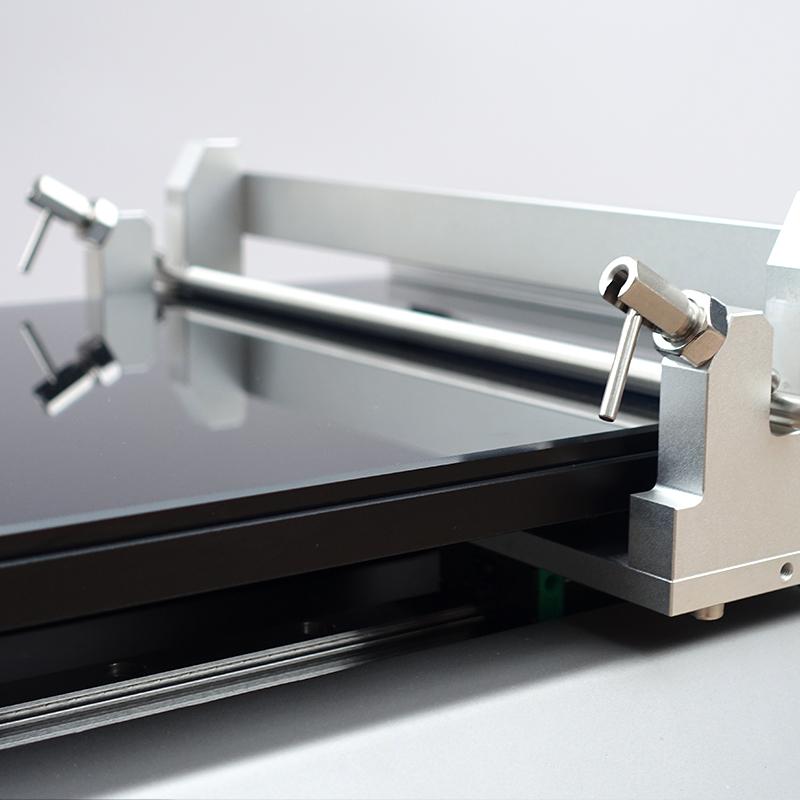

- Vacuum chuck + fixture

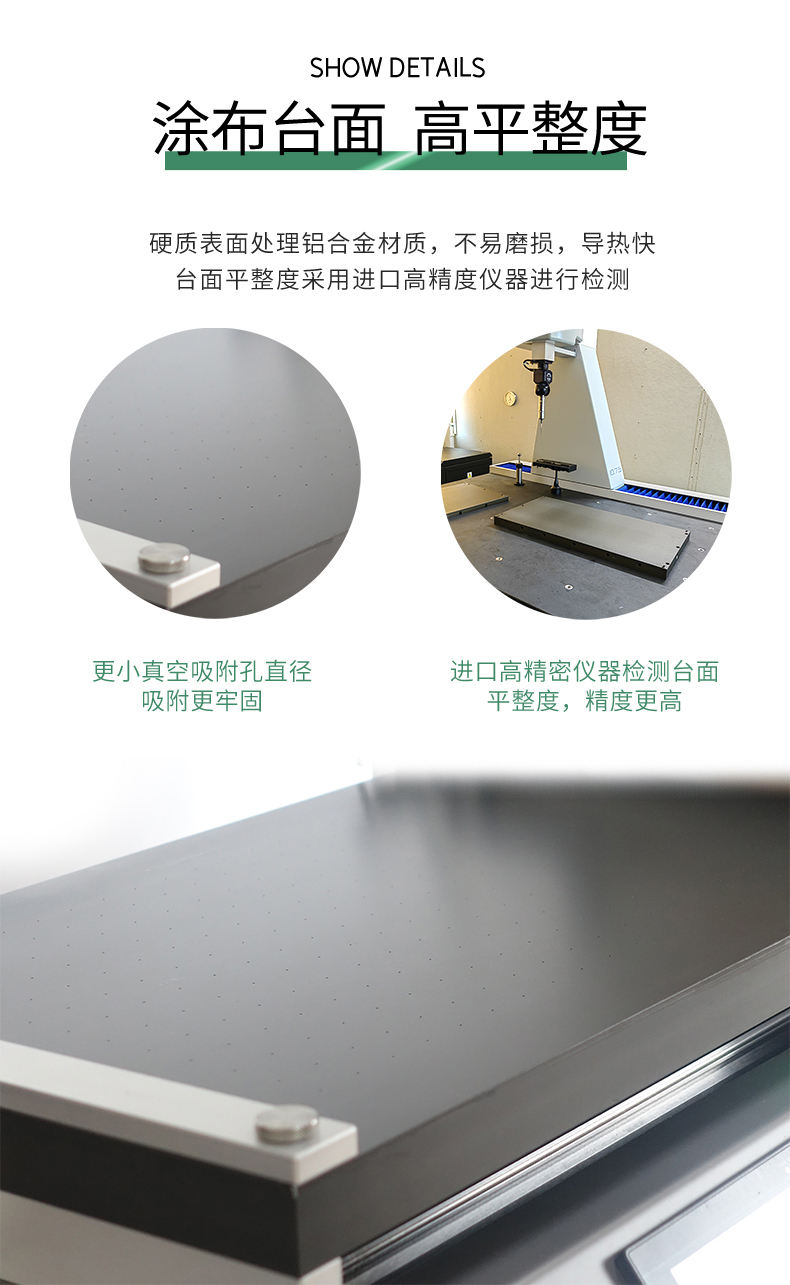

- Coating table material

- Surface hard treatment aluminum alloy

- Coating table size

- 740*330mm

- meyer rod coating thickness range

- Film thickness is different, with High Accuracy bar

- meyer rod coating accuracy

- ±0.001mm

- Vacuum Area

- 580 * 260Mm (can be customized)

- Vacuum aperture diameter

- Φ0.8mm

- Vacuum hole pitch

- 20*20mm

- Vacuumpump pumping rate

- 5.4m3/h

- Ultimate vacuum degree

- 50KPa

- Vacuumpump power

- 180W

- Vacuumpump weight

- 7.1kg

- Heating method

- Mica sheet heating (optional graphene heating, faster thermal conductivity)

- effective coating area

- 500 * 300Mm (can be customized)

- Heating temperature range

- RT +~ 180 ℃ (can be customized)

- Temperature Uniformity

- ±1℃

- coating speed

- Stepless speed regulation through cylinder valve

- customization function

- Automatic feeding system

- Feeding principle

- Pneumatic pressure feeding

- Feed Sport Mode

- Reciprocating linear motion

- Feeding back and forth traverse speed

- 2-150mm/s

- spit volume

- Adjustable (by adjusting the air pressure and the running speed of the discharge port)

- Feeding system air source

- Customer-provided compressed air, 0.6Mpa

- Residual material recovery tank

- √

- operating language

- Chinese (can be customized in English)

- display screen

- Color LCD Touchscreen

- Host power supply

- 100V~220V/50~60HZ

- power

- 1800W

Product Overview:

Automatic film coating machine is a device used to coat film in the laboratory, replacing manual film coating, automating the film coating, and improving the accuracy and efficiency of film coating. The working principle of the experimental automatic film coating machine is to evenly coat the sample on the substrate by controlling the coating head and coating parameters, forming the desired film.

This coating machine is a wire rod type automatic coating machine,With heating and vacuum adsorption,The new wire rod installation method and clamshell scraper head greatly improve the coating efficiency, easy to clean, support speed control and coating length adjustment, suitable for high-precision automatic coating of film in the laboratory, and carry out film proofing in university research institutes, new materials, lithium batteries, glue, resin and other laboratories.

Product Use:

The film coating machine is suitable for coating and sample coating of coatings, inks, paints, pastes, lithium batteries, pressure-sensitive adhesives, resins, glues, polymer materials, pharmaceuticals, etc., and can be scraped on glass, cardboard, and fabrics.

Product features:

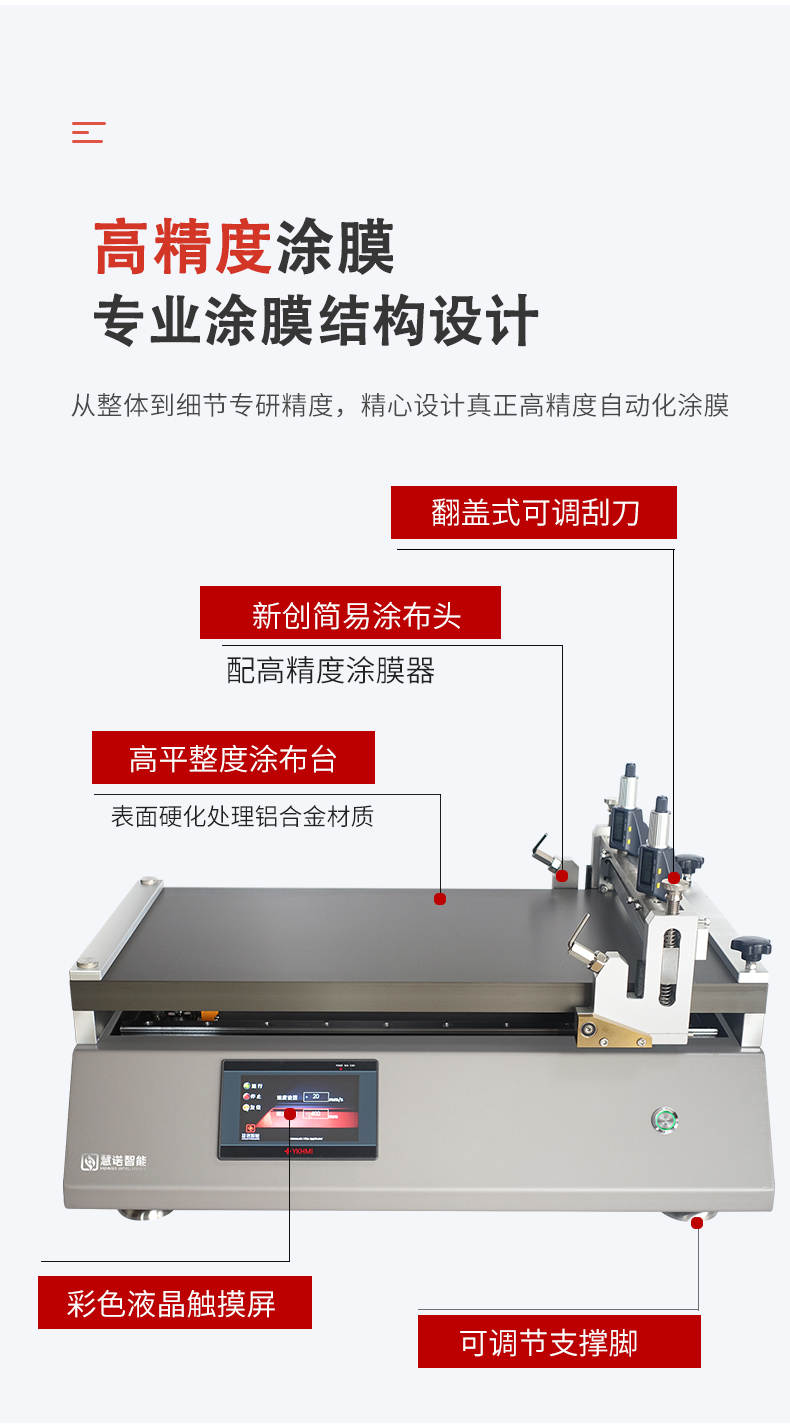

1) Surface hard treatment aluminum alloy countertop, high hardness and wear resistance, and the flatness of the countertop is tested by imported high-precision instruments.

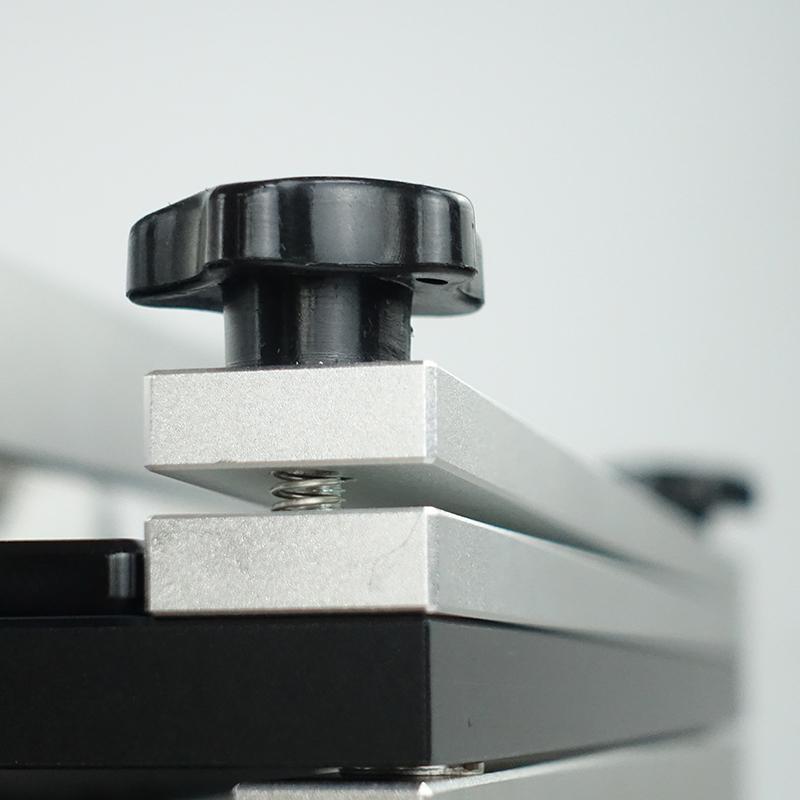

2) Big brand differential adjuster, high film thickness control accuracy

3) With heating and vacuum adsorption functions

4) Equipped with high-precision film applicator, the original imported wire rod coating film is uniform and high accuracy

5) Touch screen control panel, easy to operate

6) The coating length and coating speed can be adjusted freely

TM1300AF/03

TM1300AF/03