HUITAI GDT-150BH Programmable High and Low Temperature Damping heat testing chamber 150L

HuiTai GDT-150BH Programmable high and low temperature Damping heat testing chamberSPEC

HuiTai GDT-150BH Programmable high and low temperature Damping heat testing chamberDetails

HuiTai GDT-150BH Programmable high and low temperature Damping heat testing chamberPacking list

- SKU

- NB050710

- Temperature range

- -40~150℃

- Humidity range

- 20%-98%RH

- Temperature Fluctuation

- ≤±0.5℃

- Temperature deviation

- ≤±1℃(<85℃)

- Temperature Uniformity

- 2℃(≤50℃)

- Temperature resolution

- 0.1℃

- heating rate

- -40 ℃ → + 100 ℃ 3 ℃ -5 ℃/min (mechanical refrigeration, under standard load)

- cooling rate

- + 25 ℃ → -40 ℃ 0.7 ℃ -1 ℃/min (mechanical refrigeration, under standard load)

- Humidity range

- 20%R.H~98%R.H

- Humidity deviation

- ≤ +/- 3% RH (Humidity > 75% RH ) ≤ +/- 3% RH (Humidity ≤ 75% RH)

- Humidity stability

- ±1.5%R.H

- Humidity resolution

- 0.1%R.H

- voltage

- 220V

- Power (KW)

- 4.5

- Working size, width * depth * height (mm)

- 500*500*600

- Dimensions Approx., width * depth * height (mm)

- 750*1150*1620

- Display instrument

- 7-Inch TFT color LCD display (can be connected to RMCS control software)

- operation mode

- Fixed value mode, program, mode (preset 100 groups of 100 steps 999 cycles)

- Control mode

- BTC equilibrate Temperature Control mode + DCC (Intelligent Cooling Control) + DEC (Intelligent Electrical Control) (Temperature Test Equipment) BTHC equilibrate Conditioning Control mode + DCC (Intelligent Cooling Control) + DEC (Intelligent Electrical Control) (Temperature Humidity Test Equipment)

- Linear dispersion recording function

- With battery-protected RAM, it can save the setting value, sampling value and sampling time of the device; the maximum recording time is 350 days (when the sampling period is 1/min)

- Software Operating Environment

- The operating software of the upper computer is compatible with XP, Win7, Win8, Win10 Operating system (provided by the user)

- communication function

- RS-232 interface MODBUS RTU Communication protocol and USB Communication protocol choose one; support secondary development, provide host computer operating software, RS-232 and USB interface single device link.

- way of working

- Compression refrigeration system

- Observation method

- Heated observation window with LED interior lighting

- Temperature and Humidity Sensing

- Temperature: Class A PT100 Armored Thermocouple Humidity: Class A PT100 Armored Thermocouple dry wet-bulb temperature meter method (only works in Humidity controlled tests)

- Safety protection

- fault alarm and cause, processing prompt function, power failure protection function, upper and lower limit temperature protection function, calendar timing function (automatic start and automatic stop operation), self-diagnosis function

- check configuration

- Access hole with silicone plug (50mm left)

- Interface

- USB + 232 interface data export, signal output

- Shell material

- stainless steel

- Power supply voltage

- 220V 50Hz 32A open

Implementation standards

GB/T5170.2-2008 Temperature Test Equipment

GB/2423.1-2008(IEC60068-2-1:2007) Cryogenic test method AB.

GB/2423.2-2008(IEC60068-2-2:2007) High temperature test method BA. GB/T5170.5-2008 Damp heat test equipment.

GJBl50.3 (MIL-STD-810D) high temperature test method.

GJBl50.4 (MIL-STD-810D) low-temperature test method.

GB2423.3-93 (IEC68-2-3) Test Ca: Constant Damp Heat Test Method.

GB2423.4-93 (IEC68-2—30) Test Db: Alternating damp heat test method.

Equipment safety protection

Refrigeration system

Compressor overpressure protection

Compressor motor overheating protection

Compressor motor overcurrent protection

Humidification system

Humidification pipe dry burning protection

Abnormal protection of water supply

Abnormal protection against water shortage

Test chamber protection

Adjustable test space over-temperature protection

Air conditioning channel extreme over-temperature protection

Ultra-high temperature protection is set inside the controller

Fan motor overheating protection

Other protections

Total power supply phase sequence and phase loss protection

Leakage protection of the whole machine

Load short-circuit protection

Closed mine protection

Refrigeration process

Refrigeration compressor - French Taikang fully enclosed compressor

Working method - compressor cooling

Evaporator – High efficiency components with slope evaporator (AC&R compound spoiler type aluminum fins)

Condenser - using water cooling system to facilitate equipment movement, etc

Heat exchanger - ultra-high-efficiency SWEP plate type cold coal cold heat exchange design, which is more efficient than the traditional internal spiral type

Installation process

1. Nitrogen flushing welding process is adopted, high-quality oxygen-free copper pipe is used for low-temperature connection pipeline, and 48-hour high pressure holding and leakage prevention process to ensure welding quality.

2. The pipeline installation adopts the bending process of the pipe bender, and the turning part is not allowed to use elbow welding.

3. The low-temperature pipeline is equipped with shock-absorbing process pipes, and the refrigeration unit adopts shock-absorbing springs and foot pads for shock absorption and noise reduction.

4. The drying filter absorbs residual moisture, particles, impurities, and acidic substances in the refrigeration system.

5. The selection of solenoid valves is mainly based on well-known brands, and solenoid valve welding takes necessary spool cooling protection measures to prevent damage or reduce life.

Refrigerant - original American DuPont environmental protection refrigerant R404a, R23

Safe use conditions of equipment

Venue requirements:

The ground is flat, well ventilated, and free of flammable, explosive, corrosive gases and dust

There are no sources of strong electromagnetic radiation nearby

Equipped with a drain and floor drain near the equipment (within 2 meters of the refrigeration unit)

Ground load-bearing capacity of the site: not less than 500kg/m2,

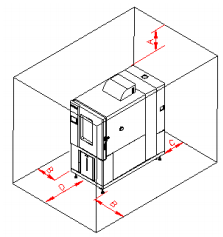

Leave proper maintenance space around the equipment

A: Not less than 30cm

B: Not less than 50cm

C: Not less than 70cm

D: Not less than 90cm

The device requires a power supply

Voltage allowable fluctuation range: AC (1±5%) 380V/220V

Frequency allowable fluctuation range: (1±1%) 50Hz

The ground resistance of the protective ground wire is less than 4Ω

The user is required to configure the equipment with a comparable capacity air or power switch at the installation site, and this switch must be independent and exclusively for the use of the equipment

The length of the power cord of the equipment is 1.5 meters

Requirements for storage environment

When the equipment is not working, the temperature of the environment should be kept within 0~+35°C (no freezing).

When the ambient temperature is below 0°C, the water remaining in the equipment should be discharged clean to prevent the water in the pipeline from freezing and damaging the pipe

Water quality requirements

Distilled water, pure water, and deionized water are acceptable (resistivity greater than 500Ω·m) (provided by users)

other

Opening the door of the chamber during the test will cause temperature or humidity fluctuations in the chamber

If the door is opened multiple times or left open for a long time during the test, or if the test sample emits moisture, it may cause the refrigeration system heat exchanger to freeze and not work properly

GDT-150BH

GDT-150BH