TQC No. 5 Ford Ford Viscosity Cup, model VF2033, filter aperture 5.2mm

SETQC sheen VF2033 Ford Viscosity CupSPEC

TQC sheen VF2033 Ford Viscosity CupDetails

TQC sheen VF2033 Ford Viscosity CupPacking list

- SKU

- NB000508

- Viscosity range

- 200~1200cSt

- outflow time

- 30~100s

- flow hole diameter

- 5.2mm

- Cup height

- 74mm

- Maximum width

- 92mm

- Cup body material

- Titanium anodic oxidation aluminum

- Filter material

- Titanium anodic oxidation aluminum

- Applicable standards

- ASTM D1200‘FORD

- Certificate

- without

- Weight

- 196g

Introduction to Aluminum Alloy Ford Cup

The TQC Ford cup is used for rapid viscosity testing of fluids that comply with Newtonian mechanics or are close to Newtonian mechanical properties. It is the most widely used measurement tool in the field of testing coating viscosity. The outFlow Cup method is also recognized by the world as a fast and effective way to measure viscosity. method.

Today's paint Ford Cups are produced according to a number of international standards that have been around for many years and specify not only the precise dimensional tolerances required in the process, but also their use and the recording of data obtained.

Each TQC brand paint Ford cup is produced under continuous quality control procedures and is engraved with a unique serial number. Most Ford cups are made of aluminum titanium alloy and stainless steel. All filters embedded in the bottom of the Ford cup are made of stainless steel.

FORD Viscosity Cups are used to test the concentration of coatings, paints and other similar products. Through the process of liquid flowing out of the hole under the Ford cup, the viscosity of the liquid is calculated and classified. This method of measuring kinematic viscosity generally uses minutes to calculate the flow time, and then uses a disk viscosity calculator to convert Unit of dynamic viscosity.

Specifications

| FORD number | model | filter pore size | Viscosity range | flow time |

| number 1 | VF2029 | 1.9 | 10-35 | 55-100 |

| number 2 | VF2030 | 2.53 | 25-120 | 40-100 |

| number 3 | VF2031 | 3.4 | 49-220 | 30-100 |

| No 4 | VF2032 | 4.1 | 70-370 | 30-100 |

| Number 5 | VF2033 | 5.2 | 200-1200 | 30-100 |

| Unit: mm, cst, s | ||||

| Other parameters | ||||

| Material | titanium anodized aluminum | |||

| standard | ASTM D1200'FORD' | |||

| weight | 196g | |||

| width | (MAX):92mm | |||

| cup height | 74mm | |||

Ford Cup Features

1. The paint Ford Viscosity Cup is designed with a deep groove at the mouth to prevent the measured liquid from overflowing.

2. Various special paint Ford cup holders

3. The production of TQC paint Ford cup goes through strict quality monitoring procedures.

4. Each cup is engraved with a unique numerical code

5. Each paint Ford cup is packed in a thick plastic box with soft material stuffed inside to protect the cup.

Options:

1. VF2067 TM1 temperature regulator for DIN and ASTM standard cups

2. VF1980 S20 special bracket designed in 2005

3. VF2062 S10 round bracket

4ï¼VF2061 S40B tripod, stainless steel ring, level

5. VF1982 can choose a temperature regulator that meets DIN standards and an S20 special bracket that meets ASTM standards.

6. VF2053 viscosity conversion disc

7ï¼D10076 C510 banknote meter LCD digital display, 9 hours, 59 minutes, 59.99 minutes

8. VF2034 certificate, M type, cup type FB10, conforms to ASTM D 1200 standard

Product details

Ford Cup Holder Type

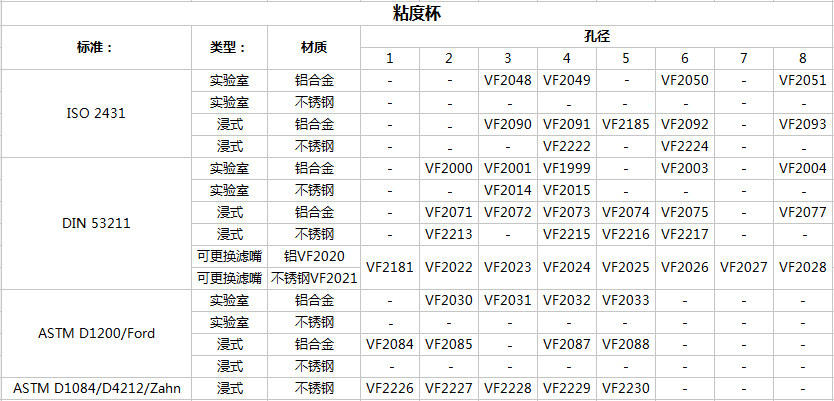

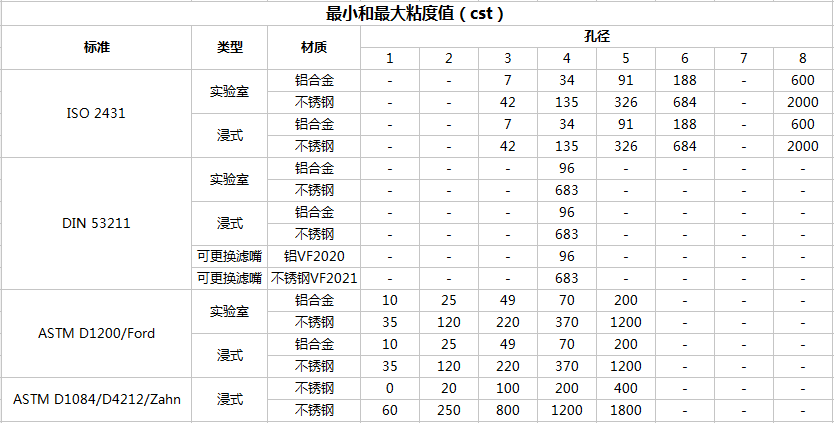

TQC model selection table

Take you into the Dutch TQC

- 1ASTM ASTM D1200《Standard Test Method for Viscosity by Ford Viscosity Cup》

- 2ASTM 《Standard Test Method for Viscosity by Ford Viscosity Cup》

- 3ASTM D1200-2010《Standard Test Method for Viscosity by Ford Viscosity Cup》

- 4ASTM D5125-2020《Standard Test Method for Viscosity of Paints and Related Materials by ISO Flow Cups》

- 5JJG 743-2018《Flow Cup Viscometers》

- 6ASTM D1200-2018《Test method for viscosity by Ford viscosity cup》

- 7GB/T 2794-1995《Determination methods for viscosity of adhesives》

- 8 《Determination of viscosity with Ford viscosity cup》

VF2033

VF2033