AISRY ASR-1023-2 Universal Testing Machine Double Column Tensile Tester, Servo 5T

AISRY ASR-1023-2 Universal Testing MachineSPEC

AISRY ASR-1023-2 Universal Testing MachineDetails

AISRY ASR-1023-2 Universal Testing MachinePacking list

- SKU

- NB050975

- Capacity selection

- 5T

- Force Precision

- ±0.5 %

- Force resolution

- 1/300000

- Effective force range

- 1~100%F.S

- Precision indication

- ±0.5%

- Test speed range

- 1-300Mm/min (can be set arbitrarily)

- Test Maximum Travel

- Effective 500mm

- Test space

- Left and right 380mm, front and rear < unk >

- Unit switch

- g、kg、N、LB、KN

- shutdown mode

- Upper and lower limit safety settings, emergency stop button, program power and elongation settings

- How to take points

- Manual point and preset point (20 points) during the test can be used for tensile and pressure test

- Machine size

- 850×600×1800mm(W×D×H)

- Machine weight

- About 450kg

Product Introduction

The tensile testing machine is mainly used for the testing of tensile, compression, bending, shear, peeling, tearing and other mechanical properties of various metals, non-metals and composite materials. The system adopts microcomputer closed-loop control, with a wide and accurate loading speed and force measurement range, and has high accuracy and sensitivity for the measurement and control of load and displacement. This equipment is suitable for metal, adhesive, pipe, profile, aerospace, petrochemical, waterproof membrane, wire and cable, textile, fiber, rubber, ceramics, food, packaging, geotextile, film, wood, paper and other manufacturing industries and product quality supervision departments at all levels, and is also suitable for teaching and demonstration work in colleges and universities.

The design of the main unit of the testing machine has the characteristics of beautiful appearance, easy operation, stable and reliable performance, no pollution, low noise and high efficiency. The design of the assistive device matches the main machine, the structure is wedge-shaped translation type, and the specimen is not subject to additional force. Clamping is easy, reliable, and does not slip.

Testing machine standards: GB/T16491-2008, GB/T228 2002, GB/T232, GB/T7314 and other implementation standards

Hardware

The main controller adopts the advanced 32-bit ARM processor of the 21st century, and the processing speed reaches the level of Pentium-level general-purpose computers, which greatly improves the overall performance of the traditional 8-bit microcontroller measurement and control system, with faster computing speed and higher control accuracy.

The core device of data acquisition adopts a new ultra-high-precision 24-bit AD from the United States, with a sampling rate of up to 500 times/second, which can capture the instantaneous change process of force, and the resolution power of the whole process is up to 500,000 degrees. And the 6-point calibration technology is used to further improve the accuracy, and the force measurement accuracy is better than the national 0.5 level standard.

The displacement encoder counting adopts 4-fold frequency technology, which increases the displacement resolution by 4 times, up to 0.0005mm.

Pulse and voltage output control mode, can control any servo motor, frequency conversion motor or DC motor with pulse or voltage control interface to achieve smooth stepless speed regulation, and there are also switching volume signal outputs such as rise, fall and stop that can be used to directly drive external relays or solenoid valves, and can be used to control DC motors or pneumatic, hydraulic and other power devices.

Advanced speed, displacement, and force three closed-loop technologies can achieve precise arbitrary waveform control.

Rich interface expansion capabilities: up to 4 24-bit analog inputs, 3 16-bit analog outputs, 3 pulse outputs, 3 AB phase photoencoder inputs, 9 switching inputs, 8 switching outputs, 1 USB interface, 1 RS232 interface, 1 RS485 interface, 4 LCD interfaces, 1 parallel micro printer interface, 1 serial micro printer interface, 1 8×4 matrix keyboard interface.

All input and output interfaces adopt high-speed optoelectronic isolation technology, which has strong anti-interference capabilities.

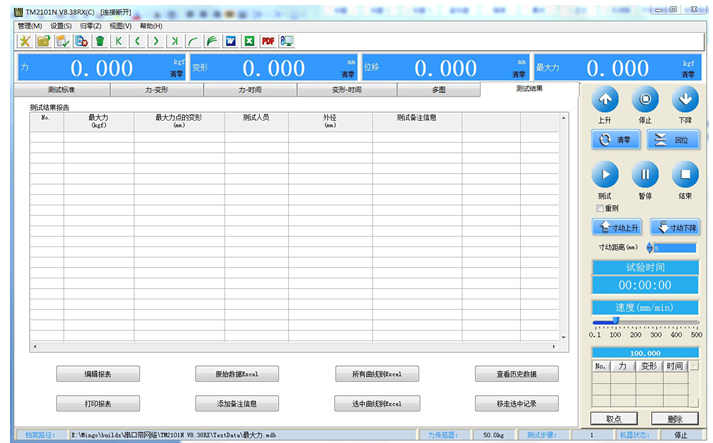

Software

The standard style of Windows, hierarchical operation and detailed help documentation and tips make it the most user-friendly software in the testing machine industry today, and your commissioning and software training efficiency will be significantly improved.

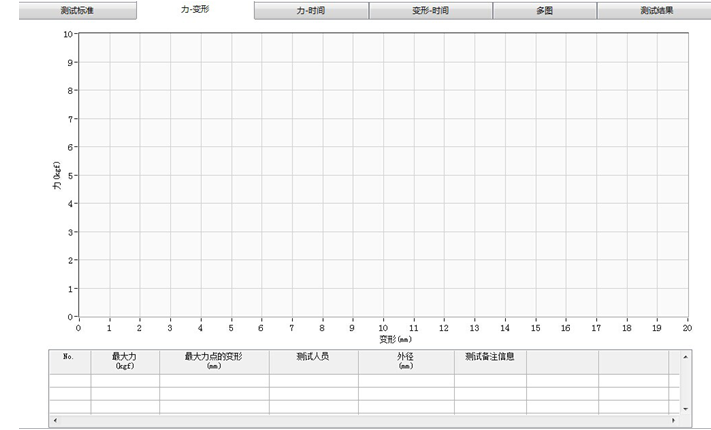

Using multi-threaded parallel processing technology, the force-displacement, force-time, displacement-time, stress-strain and other curves are displayed simultaneously in real time during the test process, and you can switch to the curve screen you want to see at will, and you can view user settings.

Standardized test process control and report output templates allow users to define any number of test standards for user calls, covering GB, ASTM, DIN, JIS, BS... and almost all test standards. Flexible and powerful test method customization mode, with fixed speed, positioning shift, constant force, constant force rate, constant stress, constant stress rate, fixed strain, fixed strain rate, etc., can realize complex multi-step nested cycle control. Functions such as automatic return, automatic breakage judgment, and automatic zeroing can be set.

Powerful data analysis statistics and curve graph analysis auxiliary tools, with functions such as zooming in, zooming out, panning, crosshair, and taking points. Multiple historical test data can be adjusted into graphs and displayed simultaneously for comparative analysis. Up to 7 interval settings, 40 manual points, and 120 automatic points It has a variety of statistical functions such as maximum, minimum, average, de-high-low average, median, standard deviation, overall standard deviation, CPK value, etc.

Fully open test result editing method, users can get any test result they want. More than 400 calculation results such as maximum force, breaking force, peeling force, tensile strength, shear strength, tear strength, maximum deformation, yield force, elongation, elastic modulus, ring stiffness, non-proportional elongation, interval minimum force, interval average force, constant elongation force take, constant force elongation, etc. are automatically calculated by the computer for users to choose and call.

The industry's innovative Microsoft Word report format is easy to use, so you can edit the beautiful reports you want as long as you know how to use Word.

The permission management system allows you to lock any functional module of the software, divide the software operation into multiple permission levels, and the unauthorized operator cannot touch the unauthorized module, making the software operation safer and more reliable.

The fully digital calibration system has a simple and efficient calibration process, and the calibration data is protected by both the upper and lower computers.

The powerful unit system can adapt to any unit system in the world, such as gf, kgf, N, kN, tf, lbf, ozf, tf(SI), tf(long), tf(short), etc., and can be expanded to any variety of units.

More heavy protection mechanisms: force, stroke, displacement over-range protection settings, upper and lower limit stroke switch hardware protection settings.

Test data management is simple, intuitive and efficient: A single test data is stored in the form of a Windows standard document, and the storage path and file name can be freely set. It avoids the shortcomings of traditional measurement and control software storing test data in database format, which will cause the database file to become larger and slower. As long as your hard drive is large enough, you can save an unlimited amount of test data.

All operations have shortcut keys, and can be connected to external manual control boxes, which can be connected to external fast up, fast down, middle up, middle bottom, slow up, slow down, zeroing, returning, testing, pause, ending, etc.

One-click switching of multiple Chinese languages: Chinese Simplified, Chinese Traditional, English, and the ten Chinese versions will be available in Japanese, Korean, Russian, German, French, Spanish, Portuguese, etc.

Green software, no installation required, can be directly copied to the computer for use (serial port driver needs to be installed first), maintenance and upgrade are simpler

Operation interface

The operation interface is simple and easy to understand, full Chinese display, and the software operation is instantaneous.

1. Equipment management functions: there are functions such as equipment parameter setting, equipment online or offline management, controller parameter setting, PID parameter online or offline adjustment, sensor direction identification, sensor default calibration, sensor calibration, sensor verification and so on;

2. Guided scheme editing: By editing the operation plan, the combination operation of various control modes such as force control, displacement control, and deformation control can be realized, so as to meet the needs of any static test operation. Test parameters can be set, such as running parameter setting, specimen parameter setting, running condition setting, and test result project management. It can carry out test operation management, such as starting test run, test operation process management, test status management, and value display management.

Curve management and analysis

During the test run, the test process is displayed in real time through single or multi-figure curves. In the non-test running state, single or multiple test curves are displayed through the query method. Curve coordinates can be preset or set online; The test data can be traversed by curves; It can pan, zoom and other operations on the curve; Feature points can be displayed on the curve, and feature points can be modified and saved. The curve can be independent or

Embedded in the test report for printout;

ASR-1023-2

ASR-1023-2