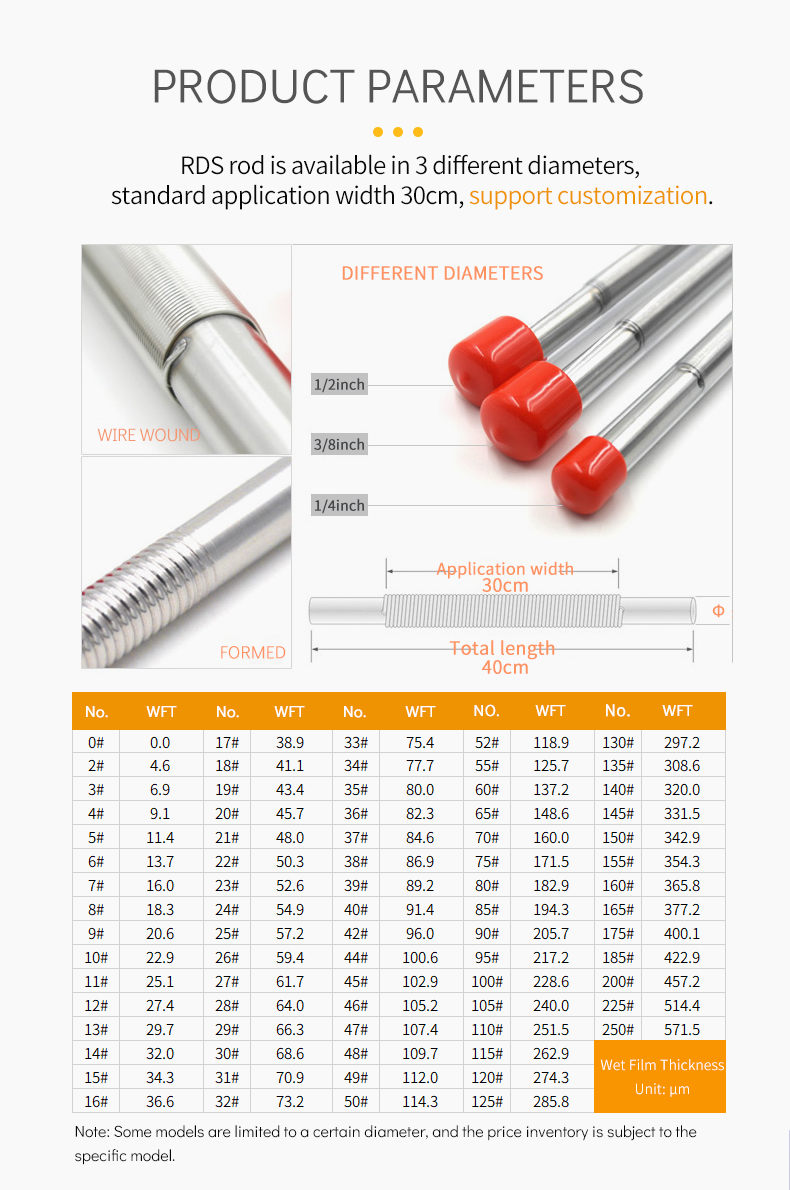

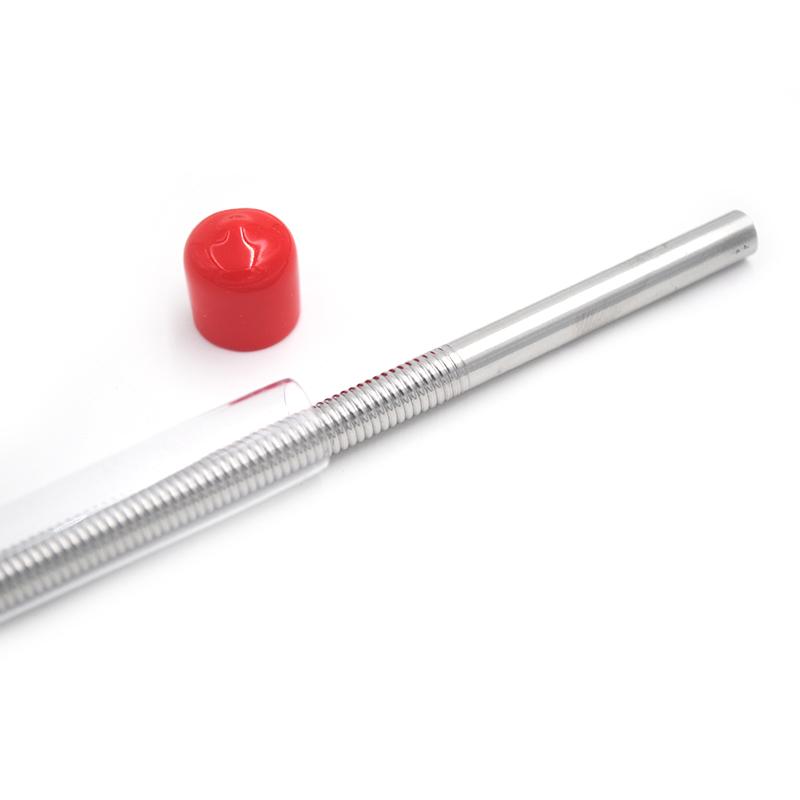

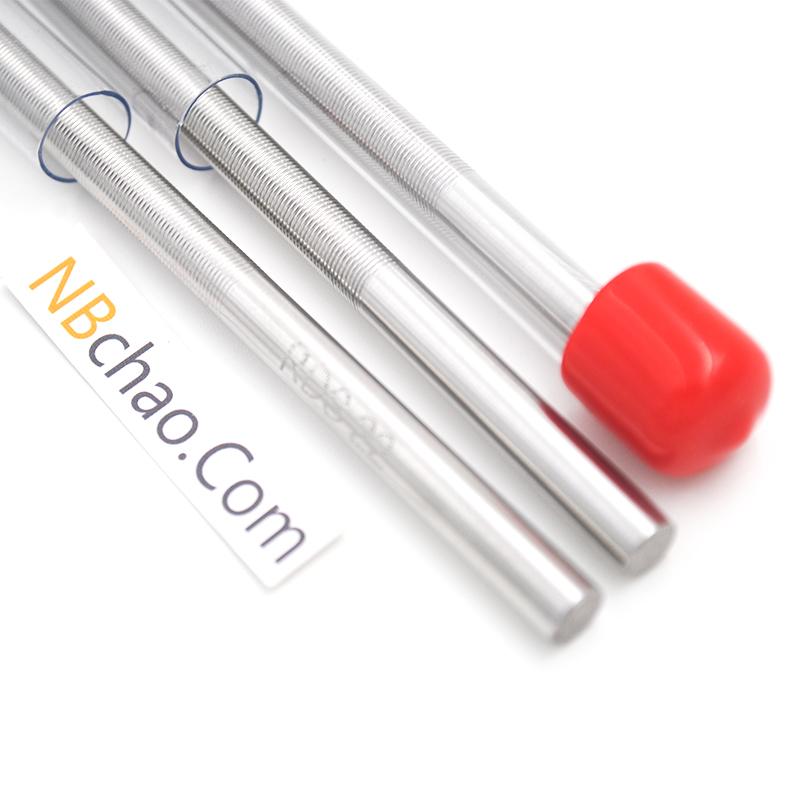

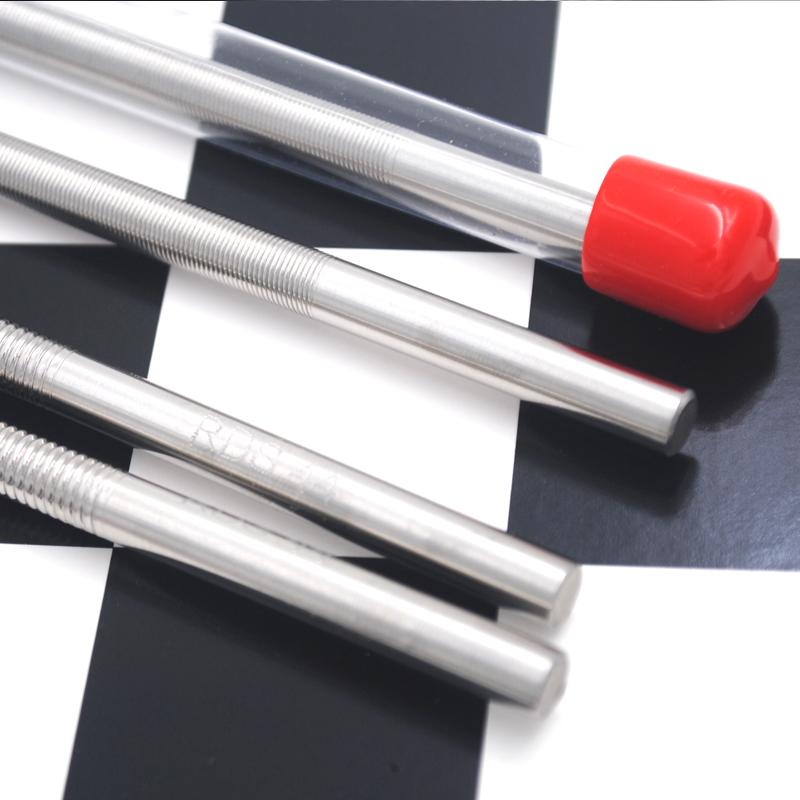

Formed, wet film thickness 4.6μm, diameter 6.35mm, Total length 400mm, Spreader width 300mm, grip width 50 + 50mm, material stainless steel.

$156.00/piece

PromotionLoading...

Coupon

Model:

Similar products

-

US RDS 2 #3/8 "Mayer Rods 4.6μm molding coating bar$ 162.00SE

US RDS 2 #3/8 "Mayer Rods 4.6μm molding coating bar$ 162.00SE -

UK RK KHC.11.0 wire-wound coating rod WFT 4μm white glue head No. 0 rod$ 168.00SE

UK RK KHC.11.0 wire-wound coating rod WFT 4μm white glue head No. 0 rod$ 168.00SE -

Japan OSP-05/400 Applicator rod WFT 5μm length 400mm$ 173.00SE

Japan OSP-05/400 Applicator rod WFT 5μm length 400mm$ 173.00SE -

UK RK KHC.10.0 coating rod WFT 4μm white rubber head No. 0 rod$ 153.00SE

UK RK KHC.10.0 coating rod WFT 4μm white rubber head No. 0 rod$ 153.00SE -

Japan OSP-04/60 Applicator rod WFT 4μm length 60mm$ 116.00SE

Japan OSP-04/60 Applicator rod WFT 4μm length 60mm$ 116.00SE

RDS 2# 1/4“ Applicator rod 1/4 "SPEC

RDS 2# 1/4“ Applicator rod 1/4 "Details

RDS 2# 1/4“ Applicator rod 1/4 "Packing list

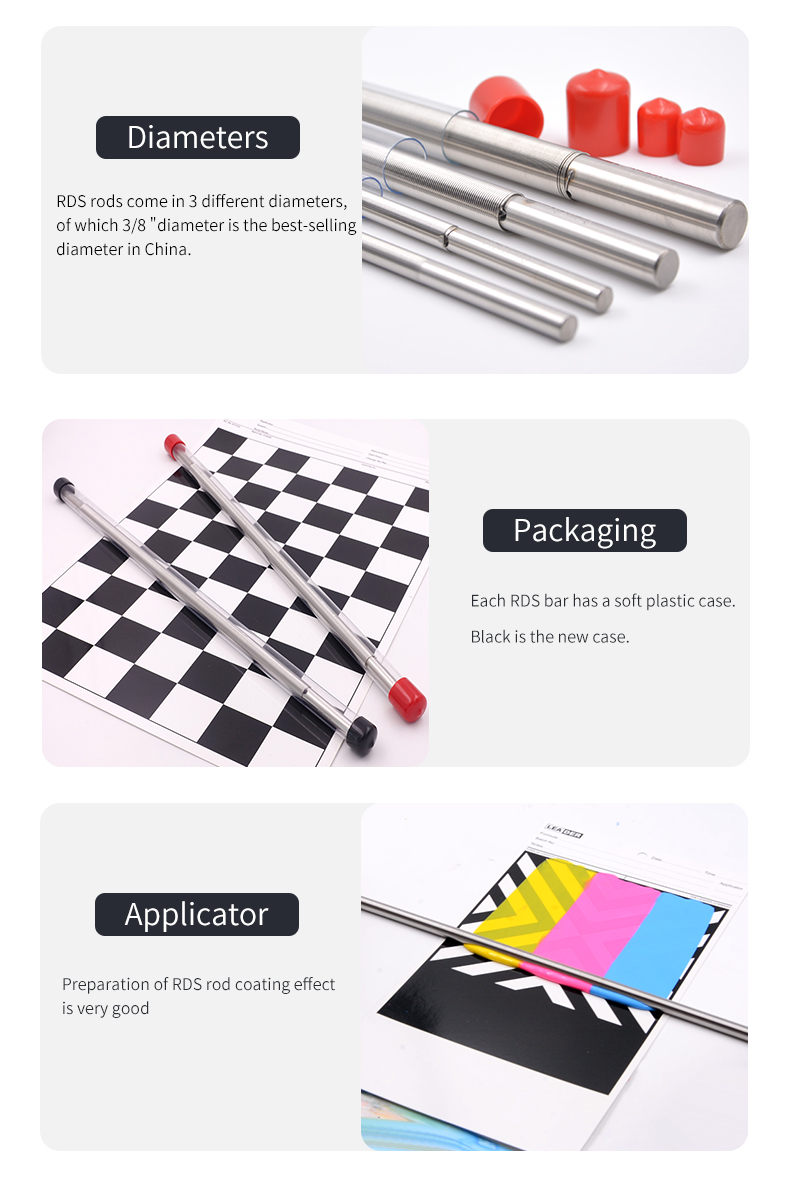

- SKU

- NB000051

- Production process

- formed

- WFT

- 4.6μm

- diameter

- 6.35mm

- Total length

- 400mm

- application width

- 300mm

- Grip Width

- 50+50mm

- material

- stainless steel

2# 1/4“

Applicator rod 1/4 "

Formed, wet film thickness 4.6μm, diameter 6.35mm, Total length 400mm, Spreader width 300mm, grip width 50 + 50mm, material stainless steel.

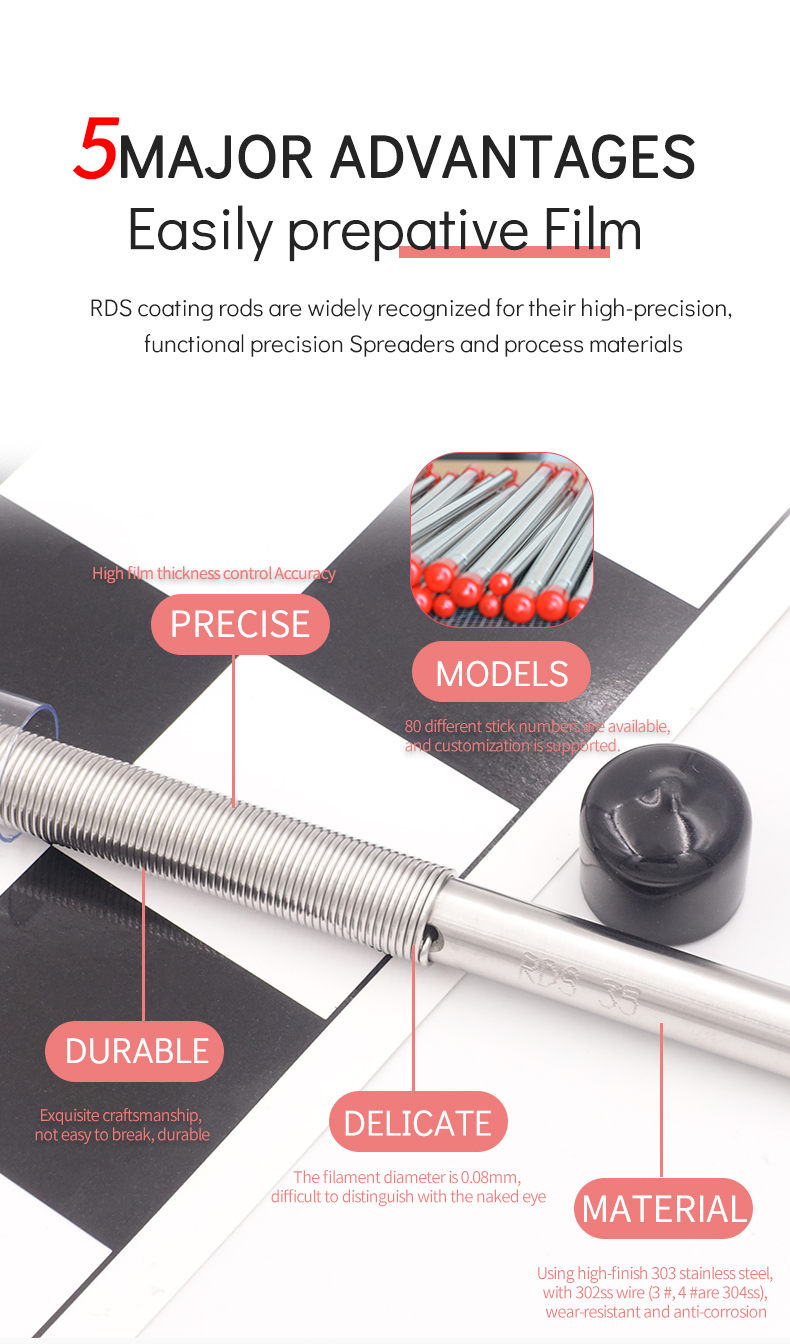

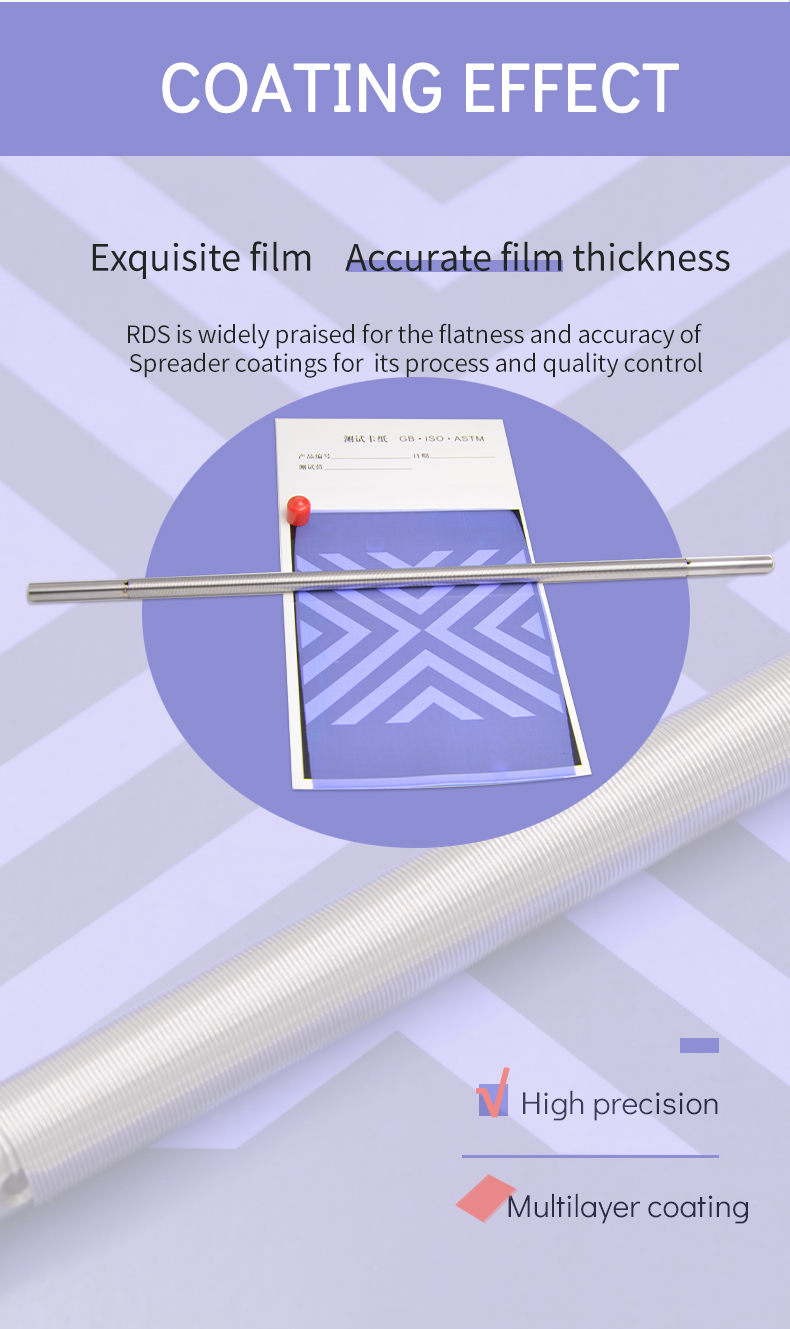

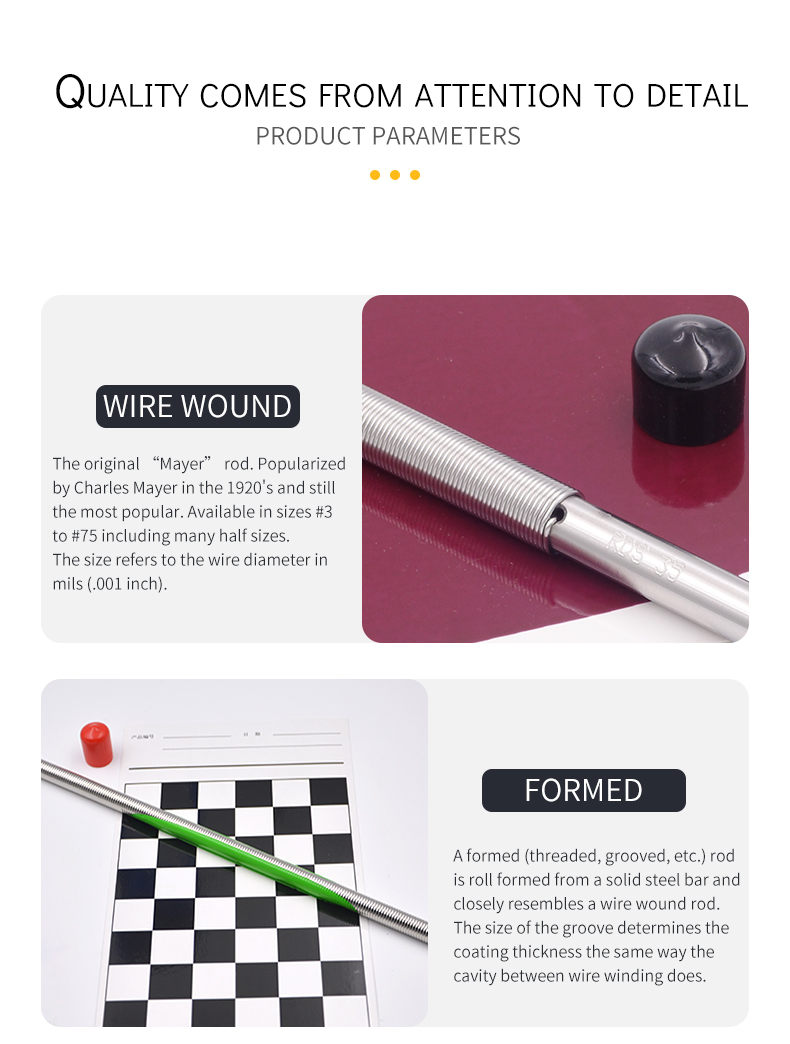

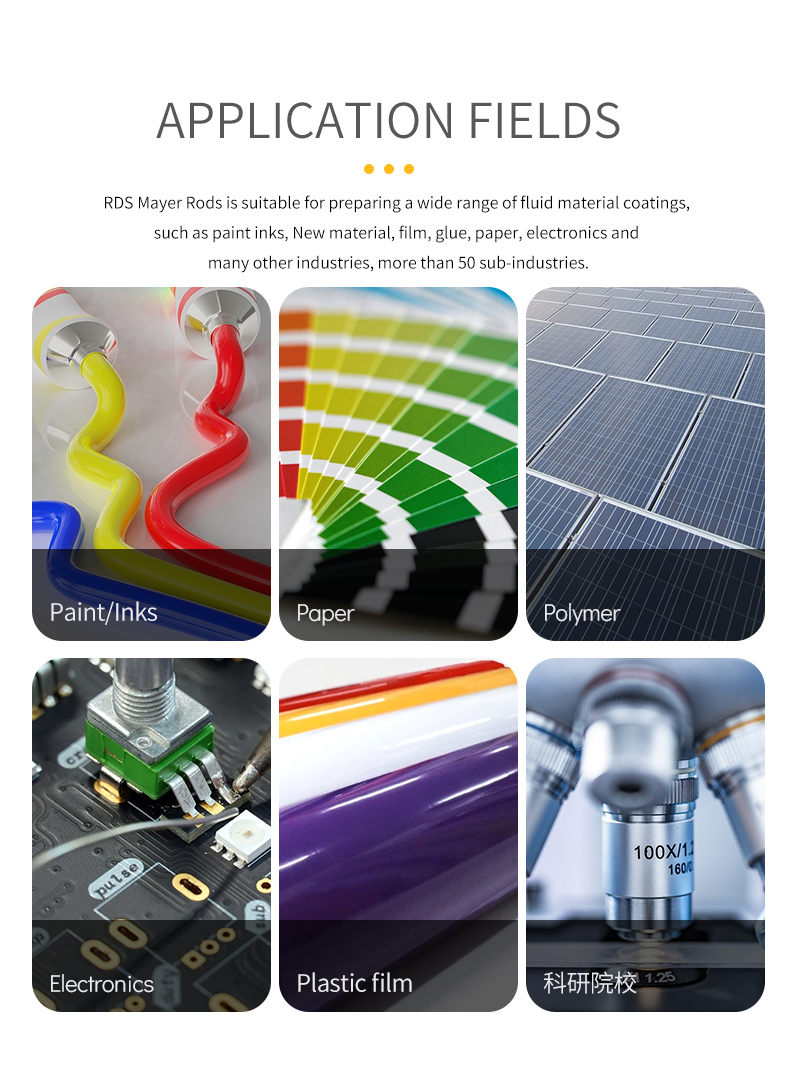

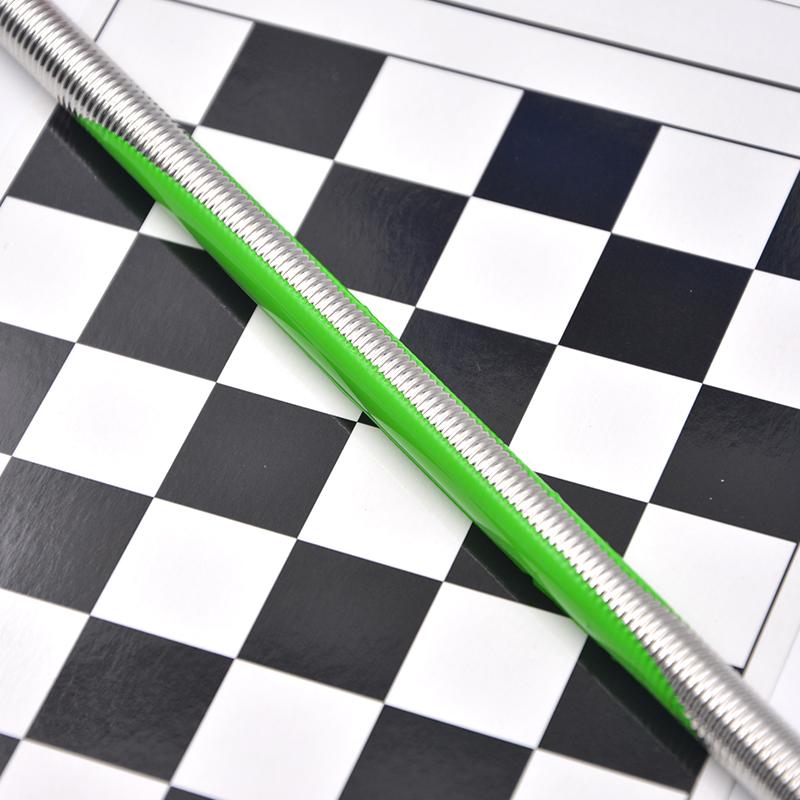

Product description

The RDS#2 wire rod coater is the smallest wire rod, and is a forming process, with a diameter of 6.35mm. The minimum size of the wire-wound wire rod coater is No. 3 wire rod. The formed coating rod is developed into a coating rod with continuous grooves through a special extrusion technology. Except for the coating amount, other aspects have inherited the advantages of the wire-wound wire rod. Advanced Made of stainless steel, wear-resistant and corrosion-resistant, the precision of the coating film is as high as 0.1 micron, and it also has its own unique advantages - continuous wire, easy to clean.

FAQ

QIs the film thickness of RDS2 rod 5 microns?

A

This one is 4.6 microns.

QHow thick is the thinnest coating? To scratch and apply fingerprint resistance

A

The thinnest 2 #stick 4.6um

QIs there anything else you can suggest if you want to apply thinner coatings?

Are there congeneric products with softer surfaces?

A

The thinnest is 1.5um. Do you mean the softness of the film? The economic solution can be matched with Drawdown Plate. If the budget is sufficient, you can consider vacuum adsorption Film Applicator.

QCan RSD 2 #Stick be used for Printing ink?

A

Hello, the wire rod is originally used in scratching film samples such as Coating Printing ink, it is OK.

QFilm thickness of about 4μm what is the rod?

A

Hello, it's an RDS 2 #forming rod.

QDo you support customization? Such as wet film thickness and length?

A

Spreader rod length and main rod diameter support customization, but wet film thickness RDS has provided dozens of specifications covering more than 200 microns, and in principle does not accept customization.

QCan this coating rod be prepative of multi-layer ultra-thin film?

A

The wire rod can be prepared for 1.5 micron ultra-thin film. Everyone must know it, but another advantage of it is multi-layer film, which is much better than I-shaped film applicator. But multi-layer film tests the flatness of the previous layers of film drying. Generally, the film thickness (such as less than 10 microns/layer) is too thin to control. The wire rod with Film Applicator is a very good solution, eliminating the problem of uneven pressure and speed of hand scraping.

QI want to do a test about the GB/T26461 standard. Is this extruded wire rod okay?

A

Sure

QCan silicone coatings be applied to quartz Glass substrates?

A

Yes, choose quartz Glass as the substrate, with Mayer Rods Coating prepared above coated on the surface of the treated quartz Glass substrate, at room temperature to evaporate the solvent into the oven, at a certain temperature curing film formation.

QRDS No. 2 rod is 1/4 diameter, is there any model with the same film thickness?

A

No, RDS #2 is a molded Mayer Rods, RDS currently wired the minimum film thickness is only #3 rod, and the molded rod is only 1/4 diameter of a series.

Knowledge

- 1Bar Spreader Technology: Principles, Applications and Advantages over Miscellaneous coating methods

- 2Technical method and application of preparing nanometer silver wire thin films with Mayer Rods

- 3Advantages of Bar Spreader in corrosion coating prepative

- 4One article introduces RDS Applicator rod type and FAQ

Standard

- 1GB/T 1727-2021《General methods for preparation of coating films》

- 2GB/T 17001.6-2022《Anti-counterfeiting printing ink—Part 6:Infrared excitation fluorescence anti-counterfeiting printing ink》

- 3GB/T 7044-2022《Colour carbon black》

- 4HG/T 5370-2018《Waterborne coatings for bicycles》

- 5HG/T 3951-2007《Water based colorants for architectural coatings》

- 6GB/T 13217.1-2020《Test method for colour and tinctorial strength of ink》

- 7HG/T 3948-2007《Hot Melt Adhesives for Sanitary napkin & Panty liner》

- 8GB/T 13217.1-2009《Test method for colour of liquid ink》

- 9GB/T 26461-2011《Gravure ink for paper》

- 10ASTM D823-2018《Paints, varnishes and related products of uniform thickness on the test board》

2# 1/4“

2# 1/4“