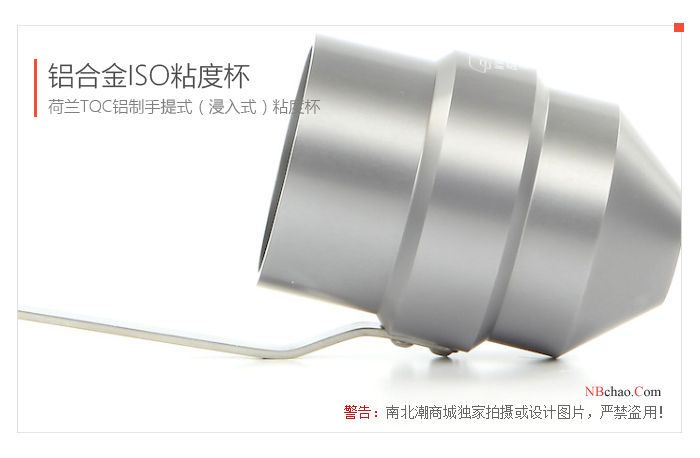

TQC VF2090 aluminum alloy immersion ISO Viscosity Cup aluminum alloy/3mm

SETQC sheen VF2090 Immersion Viscosity CupSPEC

TQC sheen VF2090 Immersion Viscosity CupDetails

TQC sheen VF2090 Immersion Viscosity CupPacking list

- SKU

- NB000514

- Viscosity range

- 7~42cSt

- outflow time

- 30~100s

- flow hole diameter

- 3mm

- Cup height

- 84mm

- Cup width

- 64mm

- Maximum width

- 74mm

- Total height

- 250mm

- Cup body material

- aluminum alloy

- Filter material

- stainless steel

- Handle material

- aluminum alloy

- Applicable standards

- din en iso 2431

- Certificate

- without

- Weight

- 281~282g

TQC VF2090/VF2091/VF2185/VF2092/VF2093 immersion ISO Viscosity Cup is a portable ISO Viscosity Cup imported from the Netherlands that is specially used for viscosity testing of coatings, paints, etc., and is suitable for testing in various laboratory situations. The pore diameter, cup body size, etc. of the TQC ISO Viscosity Cup are produced and designed according to the relevant regulations of the standard din en iso 2431 design. The material is made of aluminum alloy and is divided into five filter diameters from 3 to 8. The viscosity ranges tested are different.

Introduction to Immersion ISO Viscosity Cup

The TQC immersion ISO Viscosity Cup was originally designed for rapid viscosity and consistency evaluation of products that comply with Newtonian mechanics or are close to Newtonian mechanical properties (such as paints, paints, inks, and pigments). Today's Viscosity Cups are produced according to a number of international standards that have been developed over the years and specify not only the precise dimensional tolerances required in the process, but also their use and recording of the data obtained.

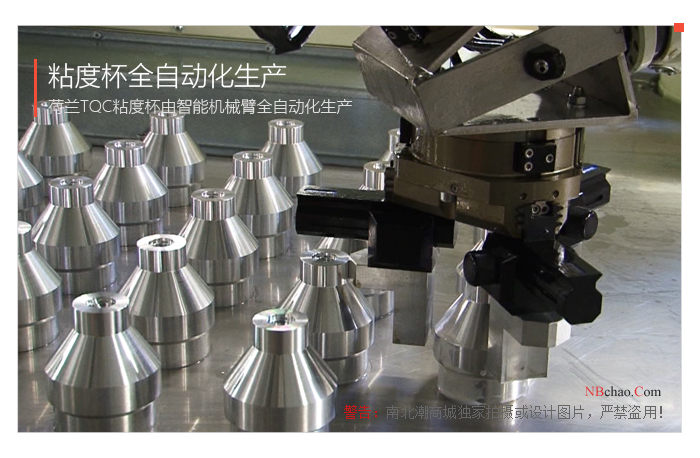

TQC brand ISO Viscosity Cups are produced under strict quality control procedures and are engraved with a unique serial number. Most Viscosity Cups are made of aluminum titanium alloy and stainless steel.

ISO Viscosity Cups are used to test the concentration of coatings, paints and other similar products. Through the process of liquid flowing out from the hole under the Viscosity Cup, the viscosity of the liquid is calculated and classified. This method of measuring kinematic viscosity generally uses minutes to calculate the flow time, and then uses a disc viscosity calculator to convert The unit of dynamic viscosity, so the Viscosity Cup is also called the outFlow Cup.

Operating procedures

1) According to the standard, the temperature of the liquid to be tested is 23 degrees Celsius, and the temperature fluctuation needs to be minimal during the test and cannot exceed +/-0.2 degrees Celsius.

2) Adjust the temperature of the liquid to be measured if necessary.

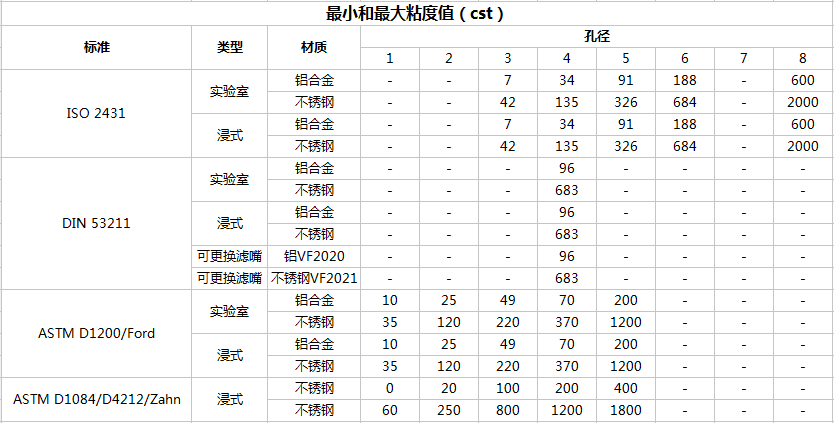

3) Select a TQC immersion Viscosity Cup with appropriate aperture according to the specification table and the expected viscosity range of the liquid to be measured.

4) Slowly immerse the TQC VF2090/VF2091/VF2185/VF2092/VF2093 aluminum alloy immersion ISO Viscosity Cup into the paint viscosity until the top edge of the cup body can be submerged.

5) Place a thermometer into the Viscosity Cup and measure the temperature of the test sample.

6) Remove the thermometer.

7) Hook the handle ring with your fingers to keep the cup vertical. Maintaining a steady state, quickly lift the Viscosity Cup from the sample. When the TQC immersion ISO Viscosity Cup leaves the test coating surface, the timing starts. During the liquid flow process, the Viscosity Cup should be kept above the surface of the sample, no more than 15cm.

8) Stop timing when the liquid stream breaks for the first time.

Specifications

| model | filter diameter | Viscosity range |

| VF2090 | 3mm | 7-42cst |

| VF2091 | 4mm | 34-135cst |

| VF2185 | 5mm | 91-326cst |

| VF2092 | 6mm | 188-684cst |

| VF2093 | 8mm | 600-2000cst |

| Other parameters | ||

| flow time | 30-100s | |

| Material | Aluminum alloy | |

| type | Handheld, immersed | |

| standard | din en iso 2431 | |

Flow cup supporting products

[need to be purchased separately]

1. Viscosity conversion disc VF2053

2. VF1982 Optional DIN compliant temperature regulator

3. VF2034 certificate, M type, cup type FB10, conforms to ASTM D 1200 standard

4ï¼VF2067 TM1 temperature regulator for DIN and ASTM standard cups

5. D10076 C510 banknote meter LCD digital display, 9 hours, 59 minutes, 59.99 minutes

Product actual pictures

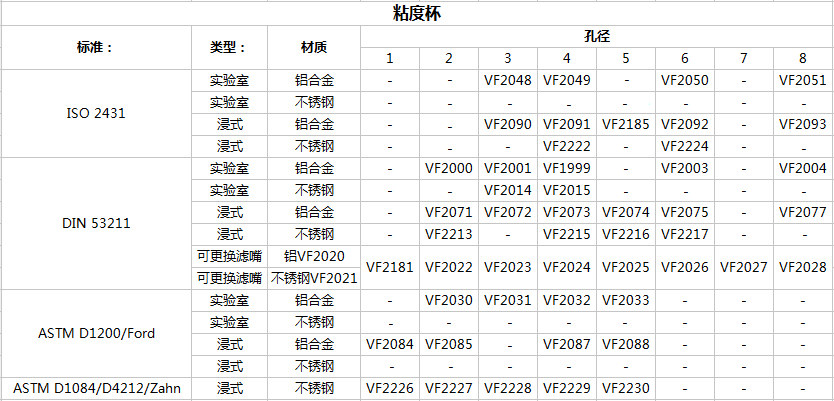

TQC model selection table

Take you into the Dutch TQC

- 1 《Standard Test Method for Viscosity by Dip-Type Viscosity Cups》

- 2GB/T 33374-2016《Ultraviolet curable coatings—Determination of volatile content》

- 3GB/T 1727-2021《General methods for preparation of coating films》

- 4ASTM D5125-2020《Standard Test Method for Viscosity of Paints and Related Materials by ISO Flow Cups》

- 5ISO 2431-2016《Paints and varnishes — Determination of flow time by use of Flow Cups》

- 6JJG 743-2018《Flow Cup Viscometers》

- 7ASTM D5125-2020《Viscosity Determination of Coatings and Related Materials by ISO Flow Cup》

- 8ISO 2431-2019《Paints and varnishes flow time with Flow Cup》

- 9GB/T 22235-2008《Determination of liquid viscosity》

- 10GB 1727-1992《Paint film general preparatory method》

VF2090

VF2090