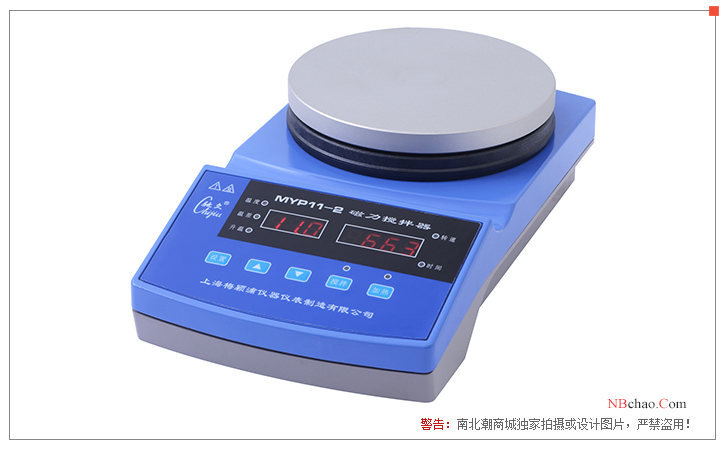

CHIJIU MYP11-2 thermostatic Magnetic Stirrer 5L/300 ℃ Timing

SEChiJiu MYP11-2 Thermostatic Magnetic StirrerSPEC

ChiJiu MYP11-2 Thermostatic Magnetic StirrerDetails

ChiJiu MYP11-2 Thermostatic Magnetic StirrerPacking list

- SKU

- NB005379

- Max. Capacity of stirring

- 5L

- Stirring speed

- 50~1500rpm

- Heating power

- 600W

- Input power

- 620W

- Temperature range

- RT+~300°C

- temperature control Accuracy

- ±0.5℃

- Timer

- 1~9999min

- Pan size

- F145mm

- Dimensions

- 280*160*90mm

- Total Weight

- 2.7kg

- Power

- AC220V ±10% 50/60Hz

- Safety protection temperature

- 350℃

Overview

Chijiu/Meiyingpu MYP11-2 constant temperature magnetic stirrer shell aluminum alloy die-casting, microprocessor control, key operation, with speed display, temperature display, timing and other functions, two digital display windows, can display the stirring speed and liquid temperature at the same time, after switching, it can also display the timing remaining time and Heating Plate temperature at the same time, three-phase brushless DC motor drive, large speed regulation ratio, stable speed, strong stirring force, Heating Plate temperature is automatically adjusted by microprocessor according to different needs, accurate temperature control.

Product display

Features

1. It has fast heating and strong stirring force, precise temperature control and timing function, suitable for unmanned operation

2. There is no need for a separate thermostat or contact thermometer, and the temperature can be accurately controlled by a random platinum resistance sensor

3. It has the function of temperature protection to prevent the Electric Heating Plate from overheating and causing accidents

4. Strong magnetic force and soft start function can prevent stir stir runner jumping.

5. Three-phase brushless DC motor drive, stable speed, large speed regulation ratio, 50rpm can stabilize the speed

6. Two LED digital display windows can display the speed, Timer Setting, liquid temperature and Heating Plate temperature respectively

7. Microcomputer control, setting data can be stored

8. Novel appearance, wide panel, suitable Viewing Angle, easy to operate

9. Precise key adjustment operation.

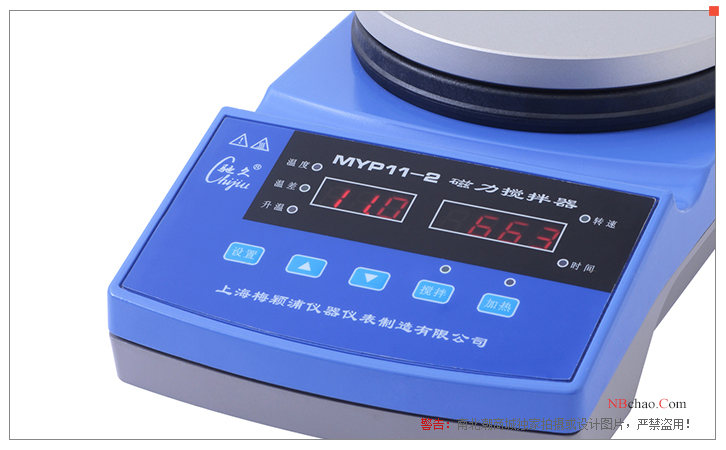

Operator panel

1. Digital display window: the left display window, in the standby state, displays the temperature of the Heating Plate to remind the user whether it can reach it, in the working state, it can switch to display the liquid temperature and the temperature of the Heating Plate, and the right display window, displays the stirring speed and Timer Setting.

2. Indicator light: On both sides of the display window, there are four function indicators of speed, time, temperature and furnace temperature, as well as two working indicators of stirring and heating. The function indicator light indicates what the meaning of the indication digit, and the working indicator indicates the working and stopping status, such as when the heating indicator light is on, the Heating Plate is powered on, and when the stirring indicator light is on, the stirrer function is started......

3. Buttons: the setting key is used for setting and switching, the up key and the down key are used to modify the setting value, the stirring key is used for stirring start and stop, and the heating key is used for heating start and stop.

use

1. Before use, insert the power cord and temperature sensor into the corresponding jack behind the machine, then place the stirrer steadily, put the beaker in the middle of the Heating Plate, put a stirring bar in the beaker, insert the temperature sensor into the beaker liquid, fix it on the bracket if necessary, connect the power supply, turn on the power switch (the power switch is located on the lower left side of the panel), the speed and furnace temperature indicator light is on, the right display window shows the speed set by the factory (or the set speed when used last time), and the left display window shows the real-time temperature of the Heating Plate.

2. Setting: When using, the user can set the stirring speed and temperature according to the demand, press the setting button to make the right display window digital jump, press the rising or descending key to set the required stirring speed, and then press the setting key, the time indicator light is on, and the same method sets the time that needs to be timed, (if you don't need timing, you can set it to "0") ), then press the setting button, the furnace temperature indicator light is on, the left display window shows 350 (factory set Heating Plate temperature), no special circumstances, no need to set (note), press the setting key again, the temperature indicator light is on, the left display window shows the factory set liquid temperature (or the set temperature when last used), set the liquid temperature with the same method as above, and then press the setting key, the setting is completed, and all the set data can be saved by power-off. (Note: If it is not activated after setting, the setting will be invalid.) The timer time needs to be set before starting after the power is turned on, and if it has been started, the setting will be invalid. )

Note: The furnace temperature, also known as the safety temperature, is set to 350°C at the factory, and when working, the microprocessor can automatically adjust it at any time according to the actual needs, so as to accurately control the liquid temperature, so it generally does not need to be reset, but if the ignition point of the experimental sample is very low, the furnace temperature should be set to be lower than the ignition point of the sample to prevent accidental fire.

3. Work operation: After the setting is completed, press the stirring button first, the indicator light is on, the stirring function starts, the stirrer gradually accelerates to the set speed, press the heating Jian, the indicator light is on, the heating function is started, the heating indicator light is on, the temperature indicator light is on, and the left display window shows the liquid temperature.

During work, press the setting button to scroll to switch the display speed, timing remaining time, temperature, and hob.

In the work, press the up or down button to directly modify the stirring speed, the modified set speed is displayed when the button is pressed, and the real-time speed is displayed one second after release, and the modified set speed is stable after reaching the modified set speed, and the modified set speed is saved before the power failure.

At the end of the working timer of the agitator, it will make a "tick" sound prompt, and stop working and be in standby mode.

4. Chijiu/Meiyingpu MYP11-2 constant temperature magnetic stirrer can not be used as an electric furnace alone, when the stirrer is working, it is necessary to start the stirring function first, and then the heating function can be started, if the stirring stops, the heating will automatically stop. If the temperature setting is high, the stirring speed should not be too low, in order to facilitate the air flow in the machine, reduce the overheating of the electronic components in the machine, do not connect the external sensor, can not be heated, at this time, if you press the heating button, the stirrer will alarm and stop. At this point, the power switch should be turned off, and then the power should be turned on again.

Precautions

1. The power socket should be well grounded.

2. When the stirrer is heating and stirring, the temperature of the Heating Plate is very high, do not touch it, in case of burns, and the power cord and sensor lead should also be kept away from the Heating Plate.

3. When operating and stirring, the liquid should be prevented from spilling on the instrument, and the surface of the instrument should be cleaned after each use. Damage caused by corrosion is not covered by the warranty.

- 1Study on micromixing measurement in magnetic stirred reactor

孟睿; 孙怀宇 - 《磁力搅拌反应器中微观混合测量的研究》

- 2Application of Magnetic Stirrer in cathode coating process

成祥源 - 《磁力搅拌器在阴极涂覆工艺上的应用》

- 3Magnetic Stirrer failure analysis and solutions

丁云兵 - 《磁力搅拌器的故障分析和解决措施》

- 4Application of Magnetic Stirrer in Titration Operation

刘耿业

- 5Talking about the control and realization method of intelligent magneticstirrer

姜志宏; 师宇杰 - 《智能型磁力搅拌器的控制方法及实现》

- 6Chijiu MYP11-2 magneticstirrer operation manual

- 7Preparation process of antifouling emulsion paint

- 8Lithium-ion battery separator performance testing scheme [with instrument list]

- 9What are the effects of object magnetism on the accuracy of Electronic Balance weighing?

刘炜 - 《物体磁性对电子天平称量准确度的影响》

- 10Synthesis of Polyvinyl Acetate Coatings

- 1GB/T 5541-2017《Disperse dyes—Determination of stability of dispersion at high temperature—Filter test of double filter papers》

- 2GB/T 6368-2008《Surface active agents - Determination of pH of aqueous solution - Potentiometric method》

- 3GB/T 33546-2017《General technica standard of electromagnetic stirrer》

MYP11-2

MYP11-2