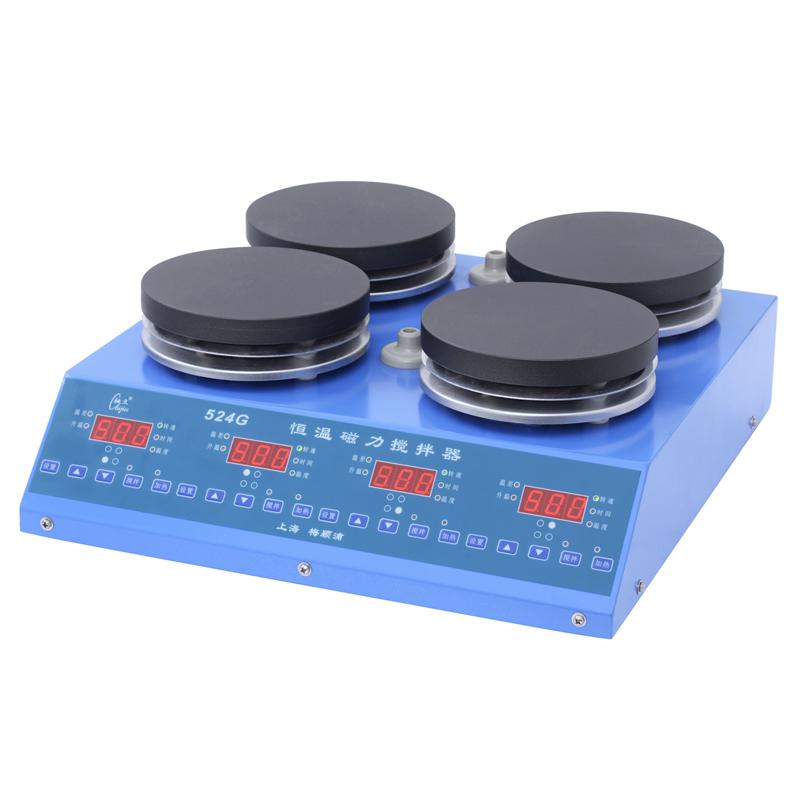

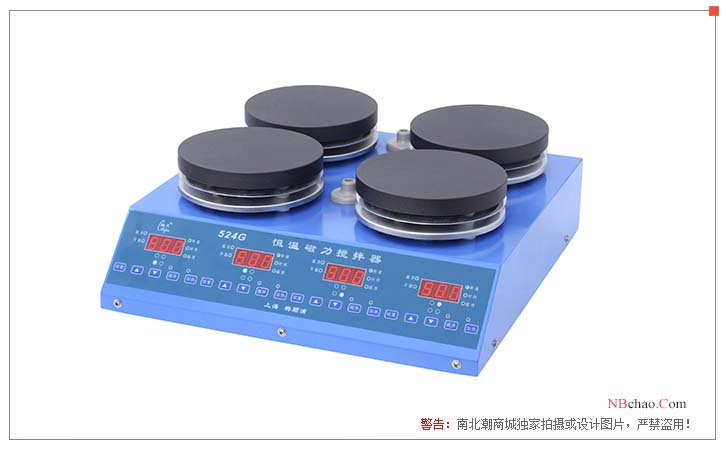

CHIJIU 524G thermostatic Magnetic Stirrer 4 station Stir capacity is 3000mlx4

SEChiJiu 524G Magnetic Stirrer (Multi-station)SPEC

ChiJiu 524G Magnetic Stirrer (Multi-station)Details

ChiJiu 524G Magnetic Stirrer (Multi-station)Packing list

- SKU

- NB005422

- Max. Capacity of stirring

- 3L

- Heating power per station

- 600W

- Temperature range

- RT+~150°C

- Dimensions

- 380*380*145mm

- Power

- AV220V±10% 50Hz

- Timer

- 0~250min

- Motor torque

- 20mN·M

- Stirring speed

- 1500rpm

Product Description

The 524G constant temperature magnetic stirrer sets the stirring speed, heating temperature, Timer Setting, etc., and maintains the drive of the brushless DC motor, the speed is stable, and each station is used independently. More accurate temperature control, better performance.

product display

Temperature Control Features

The 524G constant temperature magnetic stirrer adopts dual automatic temperature control of the Heating Plate temperature and the liquid temperature. Due to the large variables used by the user, such as the flatness of the bottom of the container, the size of the contact area with the Heating Plate, whether the container is glass or stainless steel, the amount of stirring, and the setting High-low temperature and so on. Both will affect the temperature control accuracy, so this machine is set with a temperature difference coefficient from 1 to 300, which can be set by the user. If you use a stainless steel tumbler, you can choose a smaller number, and if you use a glass beaker, you should choose a larger number. If the stirring volume is large and the setting temperature is high, select a larger number; if the stirring volume is small, the setting temperature is low, and select a small number. For example: 1000ml glass beaker (bottom is relatively flat), filled with 800ml silicone oil, the ambient temperature is 25°C, set The fixed temperature is 80°C, the temperature difference coefficient is selected as 99, and the control temperature can be stabilized at 79-80°C (the temperature displayed on the machine is measured at 80°C ± 0.5 with a thermometer)

Instructions

1. Place the stirrer stably, connect the power cord, connect the temperature sensor to the two terminal posts at the back of the machine, place the beaker containing the liquid medicine in the middle of the Heating Plate, and put a stirring bar, insert the temperature sensor into the liquid medicine, insert Connect the power plug, turn on the power switch (the power switch of the machine is behind the machine), the speed indicator light is on, and the number shows the original set speed;

2. Rotational speed setting: The four stations of this machine are operated independently, and the operation of one of the stations is taken as an example, and the rest are the same. Press the setting button once, the number will flash, use the up or down button to set the desired speed, when the speed is higher than 999, the decimal will light up, indicating that the displayed number × 10 times;

3. Time setting: press the setting button once, the time indicator light is on, use the up or down button to set the required time, if no timing is required, set the time to "0"

4. Temperature setting: Press the setting button once, the temperature indicator light will be on, and use the up or down button to set the required liquid temperature;

5. Temperature difference coefficient: press the setting button, the temperature difference indicator light is on, use the up or down button to set the required temperature difference coefficient, the first setting can be slightly smaller, if you find that the temperature rises too slowly or cannot reach the set temperature, you can reset it Set larger;

6. Press the setting button twice, the speed indicator light is on, showing the set speed, and the setting is completed;

7. Press the stirring button once, the stirring indicator light will be on, and the stirrer will run from slow to fast and reach the set speed;

8. Press the heating button once, the heating indicator light is on, heating starts, and the red temperature rise indicator light is on, indicating that the Heating Plate is powered on and heating;

9. The machine can only be heated when it is stirring. When the heating indicator is on, press the heating button again to stop heating. If you press the stirring button again, both stirring and heating will stop;

10. Display the current status: press the setting button, when the speed, time, temperature, and temperature difference indicators are on, it will display the current speed, remaining time, liquid temperature, etc. When the heating indicator light is off, the set temperature is displayed;

11. When the stirring is stopped, press the stirring key again, and the stirrer will run according to the data set last time;

12. When the machine is in the working state, press the up or down key to adjust the stirring speed. When the key is pressed, the digital display is the required speed for adjustment. After the key is released, the original display state will be restored. The adjusted stirring speed in the working state, The machine cannot be stored, and when it is turned on next time, it will work at the original stirring speed setting.

13. Except that the stirring speed of this machine can be adjusted under the working state, when other data needs to be newly set, the stirring key needs to be turned off first, and the data can be reset when pressing the setting key to an indicator light that needs to be reset;

14. When the agitator reaches the set time, there will be an alarm sound;

15. When the stirrer stops running, the power consumption is very small. If the time is short, it is not necessary to unplug the power supply.

Precautions

1. The power outlet should be well grounded;

2. When the machine is in use, the liquid medicine in the beaker should not be too full, so as not to overflow when stirring;

3. The temperature of the Heating Plate is very high when it is working, so the power cord and temperature sensor leads should be kept away from them, let alone touched;

4. If the machine is not used for a long time, it should be unplugged;

- 1Study on micromixing measurement in magnetic stirred reactor

孟睿; 孙怀宇 - 《磁力搅拌反应器中微观混合测量的研究》

- 2Application of Magnetic Stirrer in cathode coating process

成祥源 - 《磁力搅拌器在阴极涂覆工艺上的应用》

- 3Magnetic Stirrer failure analysis and solutions

丁云兵 - 《磁力搅拌器的故障分析和解决措施》

- 4Application of Magnetic Stirrer in Titration Operation

刘耿业

- 5What are the effects of object magnetism on the accuracy of Electronic Balance weighing?

刘炜 - 《物体磁性对电子天平称量准确度的影响》

- 6Comparative Analysis of Mechanical Drive and Magnetic Drive Stirs

聂鹏飞 - 《磁力传动技术在脱硫侧进式搅拌器上的应用》

- 7Talking about the use of magneticstirrer in rapid paraffin section

张穗; 程云方 - 《磁力搅拌器在快速石蜡切片中的应用》

- 8Structural Design of Magnetic Drive Stir

聂鹏飞 - 《磁力传动技术在脱硫侧进式搅拌器上的应用》

- 9Graphic Design and Application of Ultra-thin Magnetic Stirrer

陈竹; 解永平; 隋玉增 - 《超薄磁力搅拌器的设计与实现》

- 10Development process of graphic analysis magneticstirrer

524G

524G