CHIJIU MYP12-2 250W programmable Overhead Stirrer Stir power 250W

SEChiJiu MYP12-2 250W Overhead StirrerSPEC

ChiJiu MYP12-2 250W Overhead StirrerDetails

ChiJiu MYP12-2 250W Overhead StirrerPacking list

- SKU

- NB005446

- Power

- AC220±10% 50HZ

- power

- 250W

- Speed range

- 60~1500rpm

- Timer

- 1~ 9999Min/Irregular

Product Description

Chijiu MYP12-2 250W program-controlled electric mixer is driven by a brushless DC motor and controlled by a microprocessor. The speed, time and acceleration of each program are accurate, the structure is compact, and the operation is simple.

product display

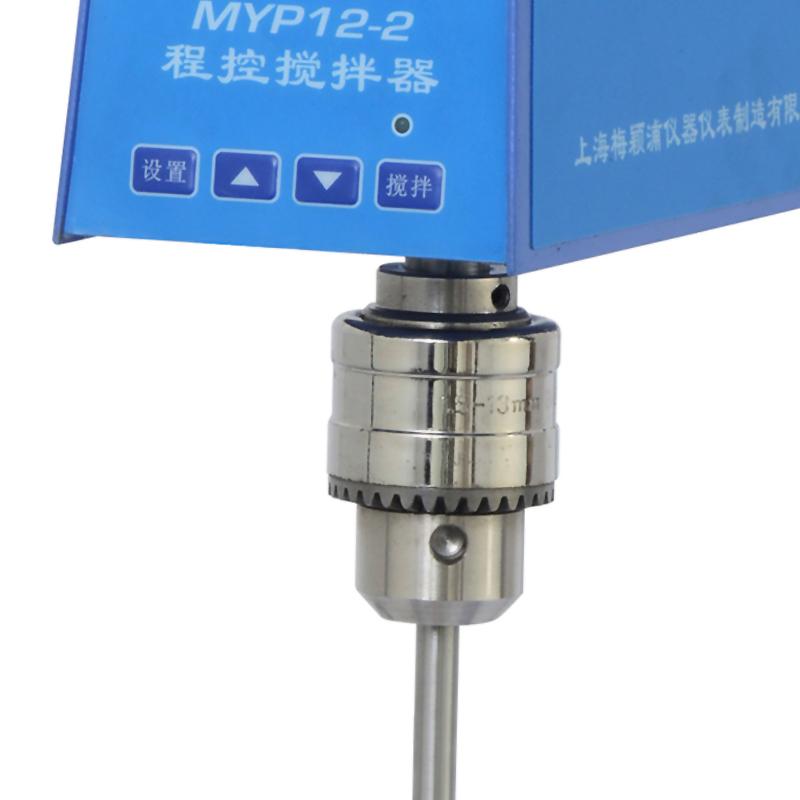

Install

First install the column on the base, then fix the main machine on the column with ten bytes, install the stirring rod, and adjust the height.

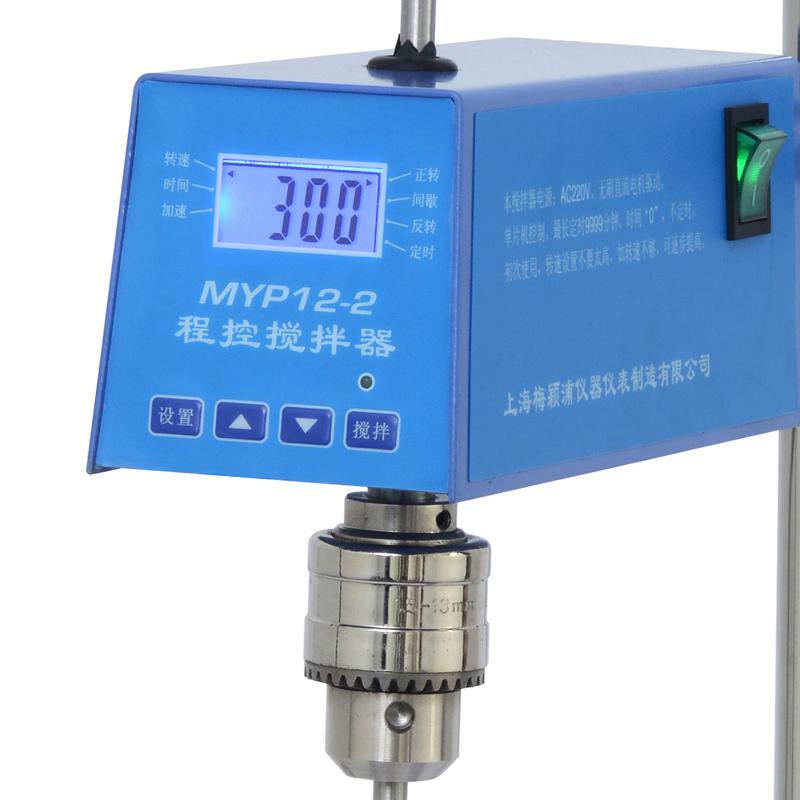

operation panel

The machine is displayed by LCD. There are nouns such as forward rotation, intermittent, reverse rotation, timing, speed, time and acceleration on both sides of the display. After starting up, one or two black arrows will appear on both sides of the LDD. The nouns pointed by the arrows are LCD. The meaning of the numbers.

Four light touch keys below the LCD: set, rise, fall, stir

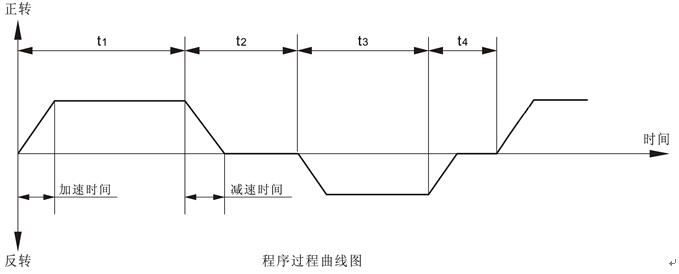

program process

After the agitator is started, the agitator rises to the set speed with an acceleration of n1rpm/s, and after the set time (t1) of forward rotation, the agitator decelerates to stop at n1rpm/s, and after the stop to the set interval time (t2), Accelerate to the set reverse speed at n2rpm/second, after the set time of reverse rotation (t3), decelerate at n2rpm/second to stop, stop to the set intermittent time (t4), repeat to the first step Forward rotation, so cycle until the timing ends.

Instructions

1. Setting, press the setting button, the arrow points to the forward rotation and speed, use the up or down button to set the forward rotation speed, press the setting button again, the arrow points to the time, and set the forward rotation time (time from start to deceleration t1 , the forward rotation time is in seconds. When t1=0, the agitator is not timing forward, that is, it will continue to rotate forward until the work timing is up, and then the work will be completed), and then press the setting button, the acceleration indicator light will be on, and the forward rotation acceleration rate is set n 1rpim/second, press the SET button again, the intermittent and time arrows appear, set the intermittent time (time t2 from the start of forward rotation deceleration to the start of reverse rotation), and then press the SET button to set the reverse rotation speed and reverse rotation time ( The time t3 from the start of the reverse to the deceleration of the reverse, the same reverse time is in seconds, when t3=0, the agitator reverses indefinitely, that is, it keeps reversing until the work timing is up, and the work is completed) Reverse acceleration n2 rpm/second and the second intermittent time (the time t4 from decelerating from the reverse rotation to the start of the forward rotation of the next cycle), and then press the setting button again, the timing arrow appears, and set the Timer Setting of the entire work (the Timer Setting is Minutes as the unit), if you do not need timing, just set the time to "0", then press the setting button, the setting is completed, press the stirring button to start the work, the set data can be saved for a long time. ~

2. Setting range:

A. Forward and reverse speed: 60~1500rpmB, Acceleration n: 1~250rpm/sec

C. t1-t4: 1~250 seconds d. Timing: 1~9999 minutes (0 means no timing)

Acceleration time = deceleration time = set speed/acceleration (seconds)

The deceleration time should be less than the intermittent time

The acceleration time should be shorter than the forward or reverse rotation time, otherwise the set speed cannot be reached

3. For one-way forward rotation, after setting the forward rotation speed, set the forward rotation time to "0" to start one-way forward rotation.

4. One-way program control, after setting the forward rotation speed, set the reverse rotation speed to "0", then forward rotation_gap_forward rotation cycle.

5. One-way reverse, set the forward rotation speed = 0, the forward rotation time is 1, the intermittent time is 1, set the reverse rotation speed, the reverse time is "0", then one-way reverse can be achieved.

Precautions

1. The power socket should have good grounding;

2. All screws should be tightened during installation.

- 1Novel Stir - Non-Splash Stir

- 2How to Prepare High Solids Polyester Resin?

- 3Development and Application of Magnetic Drive Stir

- 4Development and Application of Waterborne Colorful Coatings

吴庆喜; 石军; 吴勇; 胡娟 - 《水性多彩涂料的研制与应用》

- 5Powerbasic Stirrer and Electromagnetic Stirrer

MYP12-2 250W

MYP12-2 250W