YUEPING NDJ-5 coated with 4 cups Viscometer GB/T1723 standard, the error is only 3% Measurement

SE Boutique-

Qiwei TND-4G Benchtop Tu-4 Viscometer Viscosity cup Chrome/4mm$ 111.00SE

Qiwei TND-4G Benchtop Tu-4 Viscometer Viscosity cup Chrome/4mm$ 111.00SE -

Ander LND-1 Coating-4 Cup, Aperture 4mm Suitable for 150S Coating Viscosity Determination$ 120.00SE

Ander LND-1 Coating-4 Cup, Aperture 4mm Suitable for 150S Coating Viscosity Determination$ 120.00SE -

JINGKELIAN QND-4C Viscosity Cup measurement Coatings, paints and other viscosity Measurement range 10-150s viscosity$ 136.00SE

JINGKELIAN QND-4C Viscosity Cup measurement Coatings, paints and other viscosity Measurement range 10-150s viscosity$ 136.00SE -

JINGKELIAN QND-4A Viscometer (Bakelite Cup) is suitable for measuring viscosity of Coating products under 150 seconds$ 117.00SE

JINGKELIAN QND-4A Viscometer (Bakelite Cup) is suitable for measuring viscosity of Coating products under 150 seconds$ 117.00SE -

JINGKELIAN QND-4D Portable Viscometer GB1723-79 Standard 4mm caliber for Coatings, paints viscosity measurement$ 128.00SE

JINGKELIAN QND-4D Portable Viscometer GB1723-79 Standard 4mm caliber for Coatings, paints viscosity measurement$ 128.00SE

YuePing NDJ-5 Apply 4 cupsSPEC

YuePing NDJ-5 Apply 4 cupsDetails

YuePing NDJ-5 Apply 4 cupsPacking list

- SKU

- NB000578

- outflow time

- 30~100s

- flow hole diameter

- 4mm

- margin of error

- ±3%

- Capacity

- 100ml

- Total height

- 285mm

- Cup body material

- stainless steel

- Filter material

- stainless steel

- Handle material

- stainless steel

- Applicable standards

- GB/T 1723

- Environmental temperature

- 25±1℃

- Certificate

- none

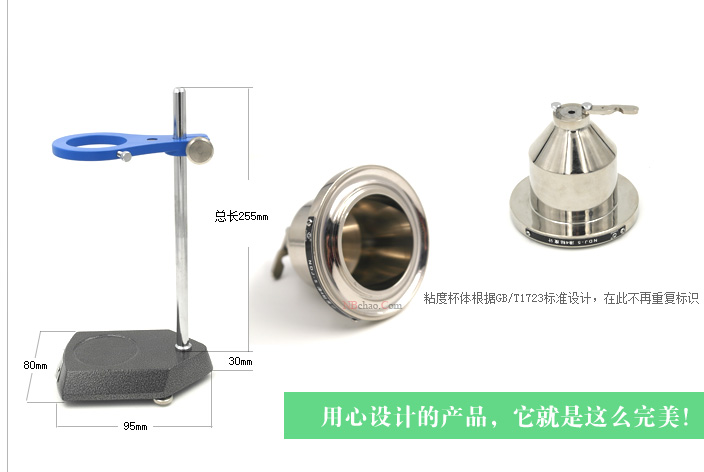

Yueping NDJ-5 viscometer is a viscometer designed in strict accordance with the GB/T1723 standard geometric dimensions, which can measure the fluid viscosity in the range of 30s to 100s for quality inspection. The Viscosity Cup capacity is designed to be 100ml. ) The measurement error is only 3%.

Yueping NDJ-5 Tu 4-cup viscometer is equipped with a Viscosity Cup, bracket and receiving cup. The reasonable design ensures the accuracy of the experimental process and easy operation. Strict quality process when the product leaves the factory, one machine and one certificate, the purchase of Yueping NDJ-5 Viscosity Cup includes a product instruction manual and a factory certificate, please rest assured to buy. NDJ-5's product engineers have spent a lot of effort on some product design details. We only state the details here:

1. Slide the switch to prevent the error caused by fingers getting stuck in the outflow port, and at the same time free your hands, making the measurement more convenient.

2. Built-in bubble level.

3. The height-adjustable bracket is equipped with double fixing screws to ensure that there is no shaking error caused by fingers and fluid flow during measurement.

4. The triangular adjustable price screw + stainless steel support rod is fixed by the bottom screw to ensure the flatness of the bracket during the experiment.

5. The Viscosity Cup is designed in strict accordance with GB/T1723 standard geometric dimensions, and the outer groove can accommodate overflowing fluid, so as not to flow out.

6. The chassis has a gravure design, which is well fixed to accept the cup.

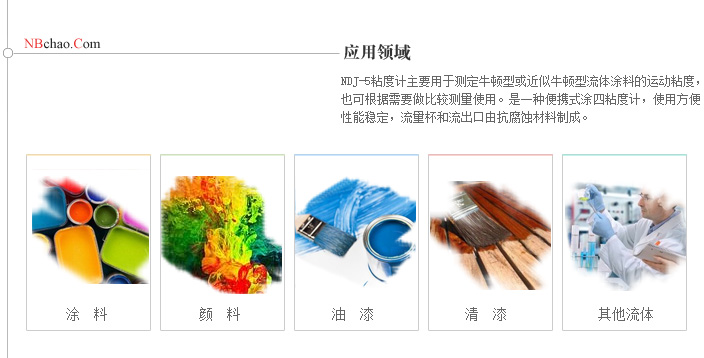

NDJ-5 Tu 4 viscometer application

Yueping NDJ-5 viscometer is mainly used to measure the kinematic viscosity of Newtonian or near-Newtonian fluid coatings, and can also be used for comparative measurement as required. It is a portable viscometer with convenient use and stable performance. The Flow Cup and outlet are made of corrosion-resistant materials.

Tu 4 cup viscometer principle

The viscosity measured by the Yueping NDJ-5 viscometer is the conditional viscosity, which is the time for a certain amount of sample to flow out of a hole with a specified aperture at a certain temperature, expressed in seconds. Use the following formula to convert the sample outflow time in seconds (S) into kinematic viscosity (mm2/s).

γ=(t-6.0)/0.223 (30s≤t≤100s)

Among them, t——outflow time (s), γ——kinematic viscosity (mm2/s)

Tu 4 cup viscometer technical characteristics

1. Yueping NDJ-5 viscometer is made of stainless steel, with a capacity of about 100ml. Its geometric size and inner wall roughness meet the requirements of "GB/T1723 Paint Viscosity Measurement Method", and its bottom is a stainless steel outflow hole.

2. Correction coefficient K: Multiply the viscosity measured by the corrected viscometer by the K value, which is the condition measured by the viscometer. The correction coefficient K should be within the range of 1±0.03, otherwise the viscometer should be replaced. The viscometer should be calibrated periodically according to the frequency of its use.

3. The difference between the measured value of the outflow time of the standard viscosity liquid with known kinematic viscosity from the Yueping NDJ-5 viscometer and the computer should be within ±3% of the calculated value.

Tu 4 viscometer installation method

1. Place the Flow Cup in the ring of the cross arm.

2. The viscometer stand consists of a level-adjustable platform and a cross. A circular blister is attached to the cross arm of the cross. Adjust the horizontal bolt of the platform to center the blister.

Tu 4 Cup Viscometer Instructions for Use

1. Before or after measurement, use gauze dipped in solution to wipe the viscometer clean and dry it in the air or with cold wind. No residual liquid is allowed to adhere to the cup or flow out of the tube hole. The inner wall and outflow hole of the cup should be kept clean, and the original smoothness should be maintained when observing the light.

2. The test should be carried out in a constant temperature room at 25±1°C, and the bracket platform should be adjusted to maintain water

flat position.

3. Stir the test solution evenly, and keep it at a temperature of 25±1°C after filtering through a sieve with no less than 567 holes/cm.

4. Inject the test solution into the viscosity agent, block the outflow hole with your fingers (if there is a stopper on the corrosive liquid cup), slowly pour the tested solution into the cup until the liquid surface protrudes from the upper edge of the cup, if there is any Bubbles, when the bubbles float to the surface, use a clean flat glass plate to push it along the edge once, and divide it to remove the protruding liquid surface and bubbles, so that the level of the measured liquid and the upper edge of the flow are on the same level.

5. Let go of your finger (or push away the stopper), the test solution will flow out vertically, take it up with the cup, and start the stopwatch at the same time, the test solution will flow out into a line, stop the stopwatch when it is disconnected, and the measured time represents its viscosity. The unit is seconds.

6. Secondary parallel test, the error shall not exceed 3% of the average value.

7. The first method should be used to clean after each use.

- 1GB/T 17001.3-2025《Anti-counterfeiting printing ink—Part 3:Thermochromic anti-counterfeiting printing ink》

- 2JB/T 3078-2015《Varnishes used for electrical insulation.Silicone impregnating varnishes》

- 3KS A0531-1993《Viscosity of Liquid - Methods of Measurement》

- 4GB/T 1727-2021《General methods for preparation of coating films》

- 5GB/T 17001.6-2022《Anti-counterfeiting printing ink—Part 6:Infrared excitation fluorescence anti-counterfeiting printing ink》

- 6HG/T 5187-2017《Automobile axle spring anticorrosive primer》

- 7HG/T 3369-2003《Micaceous ironoxide phenolic anticorrosive paint》

- 8HG/T 3349-2003《Various colour phenolic enamel》

- 9CY/T 205-2019《Screen printing - Pigment dispersion paste for textile printing process control requirements and test methods》

- 10GB/T 13217.4-2020《Test method for viscosity of ink》

NDJ-5

NDJ-5