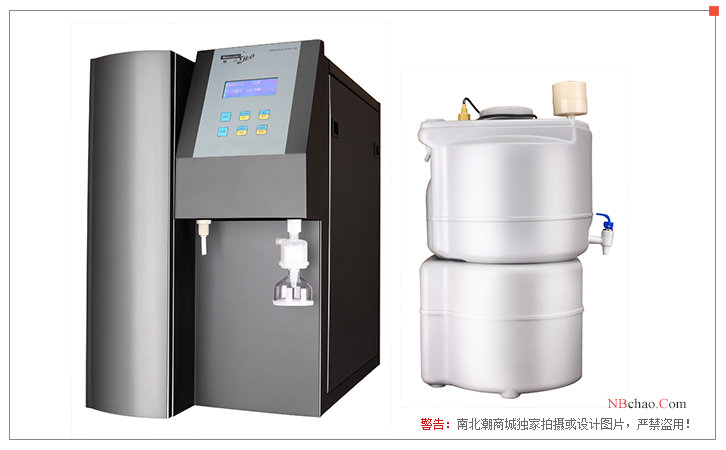

MOLECULAR MU-10L biochemical ultra-pure water machine, water production rate 10L/h

SEMolecular MU-10L Laboratory ultrapure water machineSPEC

Molecular MU-10L Laboratory ultrapure water machineDetails

Molecular MU-10L Laboratory ultrapure water machinePacking list

- SKU

- NB005817

- Inlet source

- Tap water, water pressure 0.1-0 MPa

- Power

- 220V/50HZ 200W

- Flow Rate

- 10L/h

- Flow velocity

- 1.0 L/min

- Host size

- 600*380*450mm

- Pure water storage bucket

- 25L

- Operating Environment

- The water temperature is 5~ 40 ℃, and the northern region needs an antifreeze room.

- Application

- High standard solution, buffer solution preparation, trace element quantitative analysis, atomic absorption, PCR, HPLC, liquid Mass spectrometry, emission Light spectrum, gas chromatograph, ion chromatograph, Electrophoresis, molecular biochemistry, cell fostering, microbial applications, immunology applications, protein purification analysis, TOC detection, DNA/RNA sequencing, etc

Introduction

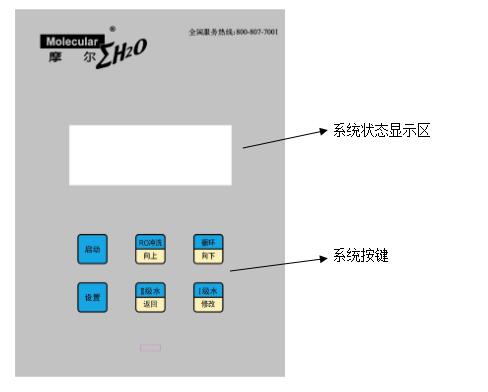

The water production rate of the Moore MU-10L biochemical Ultrapure Water System is 10L/h, and the water intake rate is 1.0L/min. MU-05L laboratory Ultrapure Water System adopts fully automatic microcomputer intelligent control, touch buttons, and human-machine dialogue menu setting interface. In addition, it adopts large-scale integrated circuit and SMC patch assembly technology, color LCD display, and human-machine dialogue menu-style setting interface. Automatic display of machine status, full process monitoring equipment, consumable replacement prompts, multiple water intake modes of random, quantitative and qualitative, water use records, alarm records, current information query, automatic calendar and temperature display, optional connection with PC.

Application purpose

High standard solutions, buffer solution preparation, quantitative analysis of trace elements, atomic absorption, PCR, HPLC, LC-MS, emission spectrometry, gas chromatography, ion chromatography, electrophoresis, molecular biochemistry, cell culture, microbial applications, immunological applications , protein purification analysis, TOC detection, DNA/RNA sequencing and other demands for ultrapure water.

Equipment function configuration

This MU-10L biochemical Ultrapure Water System is easy to operate and maintain, has low requirements on the laboratory environment, and is suitable for normal temperature and high humidity environments.

First-level purification: Use a 5μm coarse filter to remove particles, sand, suspended solids, algae, etc. in the water.

Second-level purification: Use high-quality coconut shell activated carbon to adsorb and remove residual chlorine, microorganisms, and colored and odorous substances in the water

The third level of purification: adopts precision filtration security device to improve the quality of reverse osmosis water and protect the reverse osmosis membrane.

The fourth level of purification: using high-quality original American Dow reverse osmosis membrane, the desalination and sterilization rate reaches more than 99%. Especially suitable for situations where tap water quality is poor.

Fifth-level purification: equipped with an integrated ultra-purification package Molup pack developed by Mol, with an ion removal rate of 99.999%.

The sixth level of purification: Rohm and Haas ultrapure polishing columns are used to effectively remove ions in the water, making the water quality reach ultrapure water.

The seventh level of purification: uses 254nm/185nm ultraviolet for cycle sterilization and removal of organic matter.

The eighth level of purification: uses 0.2μm German Sartorius tangential flow microfiltration membrane to intercept and remove bacteria.

Other instructions: 1. The pretreatment adopts a visible transparent cylinder to facilitate observation and replacement.

2. RO membrane intelligent anti-Graduation scheduled flushing and manual forced flushing.

3. Automatic internal circulation rinsing to maintain ultra-pure water quality.

4. Equipped with PE controllable pure Water Tank (including air filter).

5. Equipment used: DOW reverse osmosis membrane, Sartorius microfiltration membrane, Molup pack ultrapure column, ROHMHAAS polished ultrapure column, 185/254nm UV lamp, KEMFLO filter element and carbon filter. SMC solenoid valves, E-CHEN booster and delivery pumps, DMT pipe valves and fittings, magnetic resistors, Siemens electronic control components, liquid level controllers, and intelligent controllers.

Structure diagram

Product display picture

Pure water quality

The first type of water quality: GB Grade III pure water: used for cleaning experimental vessels and the most basic experiments.

The second type of ultrapure water quality:

1) Specific resistivity 18.25MΩ.cm@25℃; total organic carbon TOCâ¤1ppb

2) Absorbance (254nm, 1cm optical path): <0.001; microorganisms â¤1cfu/ml

3) Heat source <0.001EU/ml

4) Cation content (unit ppb): Fe<0.002, Cu<0.002, Al<0.003, Ni<0.001, Zn<0.005, Cr<0.001, Na<0.02, K<0.02

5) Anion content (unit ppb): Clâ<0.01, NO2â<0.02, NO3â<0.02, SO42â<0.01

- 1One article explains the development process of ultra-pure water machine

- 2How does the ultra-pure water machine save space?

- 3What is the impact of different waterways of ultra-pure water machines?

- 4What convenience does the laboratory ultra-pure water machine bring to users by using two-stage reverse osmosis purification technology?

- 5Explore new solutions for laboratory ultrapure water

- 6The feasibility study of preparing laboratory pure water by secondary electroosmosis

张云虎;林龙顺;徐德兴 - 《现代医学仪器与应用》

- 7How to reduce the operating cost of ultrapure water?

- 8Several steps for correct selection of laboratory ultra-pure water machine

- 9A little knowledge of winter maintenance of ultra-pure water machine

- 10Molar reverse osmosis membrane performance parameters and cleaning and maintenance

- 1GB/T 31531-2025《Determination of quinoline and isoquinoline in dyestuffs and textile dyeing and finishing auxiliaries》

- 2GB/T 44184-2024《Stability tests for nitrocellulose mixtures》

- 3JG/T 572-2019《Fire retardant coating for timber structure in building》

- 4HG/T 3982-2007《Electrodeionization equipment for pure-water preparation》

- 5CJ/T 168-2002《Pure water system》

- 6GB/T 41899-2022《General quality requirements for coated tinplate and ECCS used in food container》

- 7GB/T 33401-2016《Determination of the urea in liquid fluorescent whitening agent products》

- 8HG/T 5776-2020《Water-based coatings for surface of rubber sealing products》

- 9CY/T 205-2019《Screen printing - Pigment dispersion paste for textile printing process control requirements and test methods》

- 10GB/T 9779-2015《Multi-layer coatings for architecture》

MU-10L

MU-10L