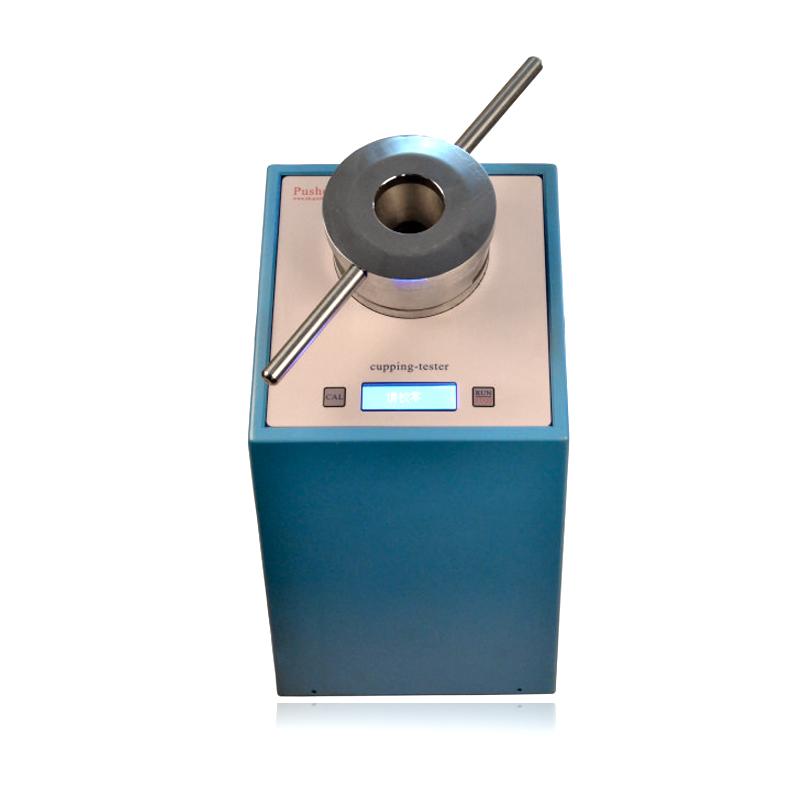

PUSHEN PS 2705 Automatic Cupping Tester

Pushen PS 2705 Cupping TesterSPEC

Pushen PS 2705 Cupping TesterDetails

Pushen PS 2705 Cupping TesterPacking list

- SKU

- NB005855

- Striker Diameter

- Φ20mm

- Impression Accuracy

- ±0.01mm

- Maximum depth of indentation

- 15mm

- indentation rate

- 0.2mm/s

- plate thickness

- ≤1.25mm

- Power Supply

- 220V AC 50Hz

- Standards

- GB/T 9753-2007、ISO 1520-2006

- Dimension

- 230*360*430mm

- Total Mass

- 35kg

PS 2705 Automatic Cupping Tester

It is used to inspect the spread and damage of single and multi-coat coatings on metal substrates.

- Motor-driven punches are extremely reproducible

- There is no need to zero the steel plate, and it will automatically reset to zero after the test, and there is no cumulative error

- High-precision position sensor with indentation accuracy of up to 0.01 mm

- Comes with a 10x illuminated magnifier as required by the standard for easy observation and judgment of test results

- Plates up to 1.25 mm thick can be measured

- Digital display, all functions are controlled by 2 buttons

Procedure

Insert the plate into the opening of the instrument with the coated side facing up

Medium force clamps the plate using a clamping device

Start the cupping instrument and observe the surface of the test plate through a magnifying glass

At a constant speed of 0.2mm/s, the steel ball is automatically topped

When the first crack is observed, stop the cupping instrument immediately

The cupping depth value is read out on the digital display

Perform at least three tests on one test plate

Meets standards

GB/T 9753-2007 Paints and varnishes-cupping tests

ISO 1520-2006

PS 2705

PS 2705