Pushen ZHY Scratch meterSPEC

Pushen ZHY Scratch meterDetails

Pushen ZHY Scratch meterPacking list

- SKU

- NB005881

- Scribe length

- 100mm

- Scribe traverse speed

- 30mm/s

- Scribe ball diameter

- 1mm

- Load (loading) range

- 50~2000g

- Maximum size of test sample

- 150*70mm

- meet the standard

- GB/T 9279-2007、ISO 1518、ISO 12137-2、ASTM D 2197、ASTM D 5178

- Load (loading) range

- 1 each for 1000g/500g/200g, 2 each for 100g/50g

- Power supply Voltage

- 220V AC 50Hz

- Dimension

- 380*300*180mm

- Calibrated Certificate

- none

- Shipment Weight

- 30kg

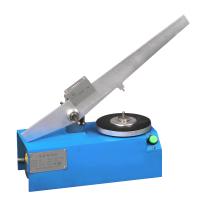

ZHY Automatic Scratch Meter

It is used to test the scratch resistance of metal surface coatings, such as coil paints, can inks, metallic paints, automotive surface coatings, etc.

It is also suitable for the evaluation of scratch resistance of single coat or composite coating of color-coated sheets.

The scratch resistance of the coating is evaluated by the maximum load of the spherical steel needle to cut the coating or not to scratch the coating at a certain weight.

During the test, a hemispherical needle with a diameter of 1 mm is used to slowly touch the surface to make a scratch about 10 cm long.

Depending on the purpose of the test and the load loaded, different degrees of penetration can be observed, ranging from surface traces to effective penetration.

The motor drives the sample to make gentle contact with the needle, which passes over the sample and stops automatically when it reaches the end point.

The contact between the scribe needle and the metal substrate is identified by a voltmeter, which shows that an electric current is passing through the sample when the coating of the sample is cut.

Meets standards

GB/T 9279-2007 Scratch test for basecoat and varnish

ISO 1518,12137-2

ASTM D 2197,D 5178

Technical parameters

Ordering number | 2690 |

Input Voltage | 220V AC 50Hz |

Diameter of the scribing needle | 1 mm |

Load weights | 50-2000 g |

Running the trip | 100 mm |

Template size | 150×70 mm |

Running speed | 30 mm/sec |

Dimensions | 380×300×180 mm |

Shipping weight | 30 kg |

Shipping list

Automatic scratch meter

2 spare stitches

1 load weight 1 each for 1000 g/500 g/200 g and 2 for 100 g/50 g

Instruction manual

- 1ISO FDIS 1518-2010《Paints and varnishes. Scratch test》

- 2 1518-2010《Paints and varnishes. Scratch test》

- 3ISO 12137-2011《Paints and varnishes Determination of mar resistance》

- 4GB/T 17657-2013《Test methods of evaluating the properties of wood-based panels and surface decorated wood-based panels》

- 5ASTM D5178-2021《Abrasion resistance of organic coatings 》

- 6ASTM D2197-16-2022《Evaluation of adhesion of organic coatings by scratch method》

- 7ISO 12137-2-1997《Paints and varnishes - Determination of scratch resistance - Part 2: Method of scribing with tip》

- 8ISO 1518-1992《Paints and varnish scratch test》

- 9GB/T 9279-2007《Paints and varnishes scratch test》

- 10GB 13452.4-2008《Filament Corrosion Resistance Test of Films on Steel Surfaces of Paints and varnishes》