Defelsko PosiTector 6000 F1 Coating Thickness Gauge Iron metal substrate nonmagnetic coating

SEDefelsko PosiTector 6000 F1 Coating Thickness GaugeSPEC

Defelsko PosiTector 6000 F1 Coating Thickness GaugeDetails

Defelsko PosiTector 6000 F1 Coating Thickness GaugePacking list

- SKU

- NB000595

- Measurement principle

- Magnetic Induction

- Measurement range

- 0~1500μm

- margin of error

- ±1%

- Resolution

- 0.1μm

- probe

- F probe (universal)

- statistical function

- Measurement times, MAX Maximum, MIN Minimum, Average, Standard deviation

- icon function

- without

- Power Supply

- 3 * AAA alkaline battery

- Standards

- ISO 2178/2360/2808、PrEN ISO 19840、ASTM B499/D1186/D1400/D7091/E376/G12、BS3900-C5、SSPC-PA2等

- Calibrated Certificate

- Yes.

- Language

- Chinese, English

- Display screen

- 2.8-Inch color touchscreen

- Interface

- USB

- supporting software

- PosiSoft Software Suite

- Machine Weight

- 137G (without battery)

- Machine size

- 127*66*25.4mm

- Data storage

- 1000 Measured values

- Test environment

- Ferrous metal substrate nonmagnetic coating environment

- Defelsko calibrated standard

- STDS1、STDA1

- screen image saving

- One hundred.

- Protection level

- IP65

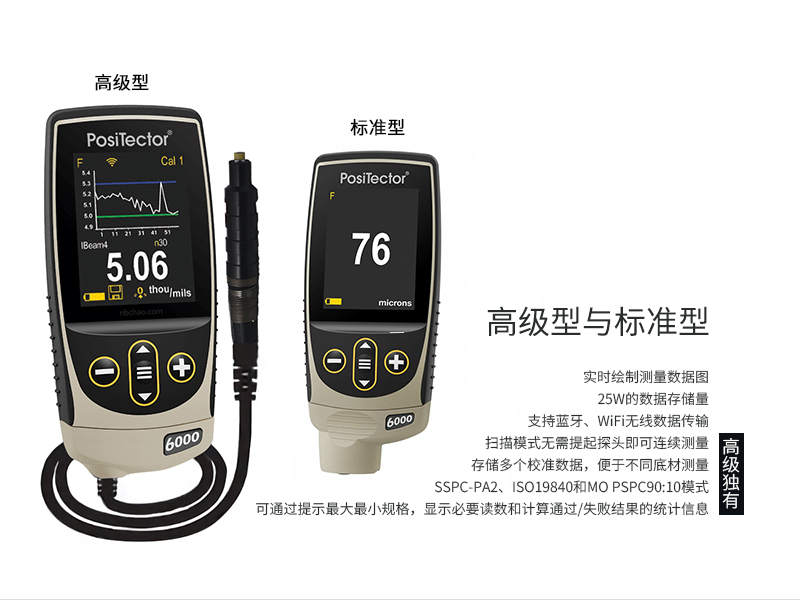

Introducing the Defelsko Coating Thickness Gauge PosiTector 6000 F1

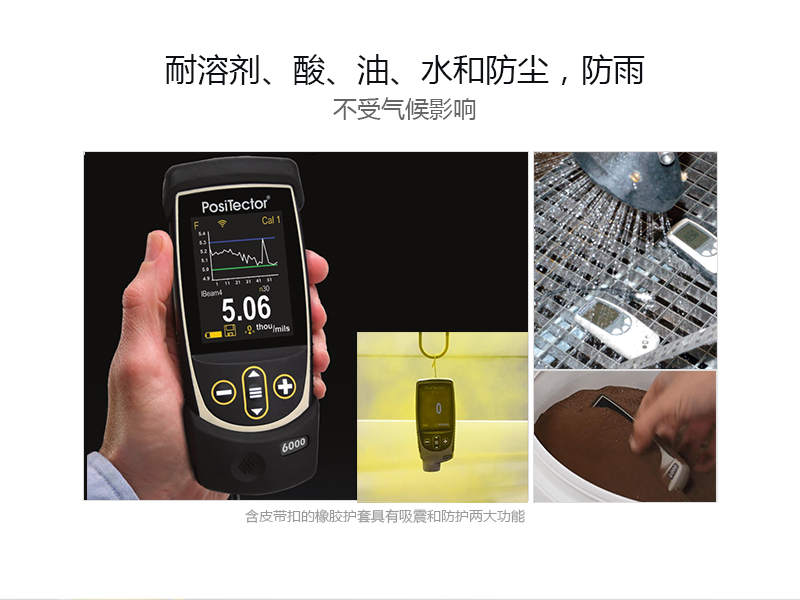

The Defelsko PosiTector 6000 F1 Coating Thickness Gauge is a general-purpose conjoined probe type coating Thickness Gauge for non-magnetic coatings on ferrous metal substrates (e.g., steel) with a thickness range of 0~1500 microns.The PosiTector 6000 F1 Coating Thickness Gauge is designed to test and operate the entire gauge with three buttons, menu-based navigation simplifies operation, and the rubber boot provides waterproof, dustproof, and oil-proof features to ensure the longevity of the Coating Thickness Gauge.

1. Single-function type:

Substrate: Ferrous metal (steel)

Coating: Non-magnetic coating

F1 – ferrous metal substrate (steel, iron, etc.) – conjoined probe type

2. Monochrome display, capable of storing 250 readings, can be browsed or downloaded

Recommended reading

★《How do you choose the Defelsko PosiTector 6000 Coating Thickness Gauge?》

★Defelsko PosiTector 6000 Series Coating Thickness Gauge Details (Text Version)

- 1HG/T 3240-2007《Micro-computer film-thickness tester》

- 2QJ 990.3A-2011《Inspection methods of coating.Part 3:Measurement of coating thickness》

- 3NF EN ISO 2808-2007《Paints and varnishes - Determination of film thickness.》

- 4GB/T 42541-2023《Coated steel pipes for gas piping》

- 5GB/T 7991.5-2014《Test method of viterous and porcelain enamels—Part 5:Determination of thickness by electromagnetic mothod》

- 6JJG 818-2018《Magnetic and Eddy Current M easuring I nstrument for Coating Thickness》

- 7GB/T 1727-2021《General methods for preparation of coating films》

- 8HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 9ASTM B499-2021《Standard Test Method for Measurement of Coating Thicknesses by the Magnetic Method: Nonmagnetic Coatings on Magnetic Basis Metals》

- 10ISO 2178-2016《Non-magnetic coatings on magnetic substrates — Measurement of coating thickness — Magnetic method》

PosiTector 6000 F1

PosiTector 6000 F1