TENCAN Powder XQM-60 Vertical Planetary Ball mill 60L

TENCAN Powder XQM-60 Vertical Planetary Ball millSPEC

TENCAN Powder XQM-60 Vertical Planetary Ball millDetails

TENCAN Powder XQM-60 Vertical Planetary Ball millPacking list

- SKU

- NB005985

- Power

- 380V-50HZ

- Motor Power

- 7.5kw

- Total running time

- 1~9999min

- alternate running time

- 1~999min

- Adjustable Rotation speed - revolution

- 27~174rpm

- Adjustable Rotation speed - Rotation

- 40~260rpm

- Noise level

- ≤60±5dB

- Speed regulation mode

- Frequency conversion speed regulation

- Device Weight

- 900kg

- Equipment Volume

- 1600*990*1250mm

- Processing Capacity

- 60L

- Can be equipped with ball mill tank specifications

- 10~15L

- station number

- 4pcs

- Can be equipped with ball mill tank specifications

- 10L

- Transmission mode

- gear drive

- Operating Mode

- Two or four ball milling tanks work simultaneously

- Maximum sample loading

- Two-thirds of the Volume of the ball mill tank

- Ball mill tank Volume

- 5L-50L per can, total Volume 20L-200L

- Feed particle size

- Soil material ≤ 10mm, Miscellaneous material ≤ 3mm

- Minimum discharge particle size

- 0.1μm

- Speed regulation mode

- Frequency conversion stepless speed regulation

Planetary ball mill principle

Tianchuang Powder XQM-60 vertical planetary ball mill has small size, full functions, high efficiency and low noise. It is a satisfactory choice for scientific research institutions, universities and corporate laboratories to obtain research samples (four samples can be obtained simultaneously for each experiment) The equipment is equipped with a vacuum ball mill tank, which can grind samples under vacuum.

Planetary ball mill application

Planetary ball mills are widely used in geology, minerals, metallurgy, electronics, building materials, ceramics, chemical industry, light industry, medicine, environmental protection and other departments. They are suitable for electronic ceramics, structural ceramics, magnetic materials, lithium cobalt oxide, lithium manganate, catalysts, etc. Phosphor powder, long afterglow luminescent powder, rare earth polishing powder, electronic glass powder, fuel cell, zinc oxide varistors, piezoelectric ceramics, nanomaterials, wafer ceramic capacitors, MLCC, thermistors (PTC, NTC), ZnO Voltage Production field of sensitive resistors, dielectric ceramics, alumina ceramics, zirconia ceramics, phosphor powder, zinc oxide powder, cobalt oxide powder, Ni-Zn ferrite, Mn-Zn ferrite and other products.

Planetary ball mill features

The planetary ball mill is stamped with high-precision molds, which is generous and refined, high-end and stable; the machined parts adopt CNC processing technology, the planetary disk is integrally cast and formed, and the transmission gears are made of precision gears made of special materials to ensure smooth and quiet operation of the equipment at high speed; the grinding jar is tightly pressed The device is easy to operate, safe and reliable.

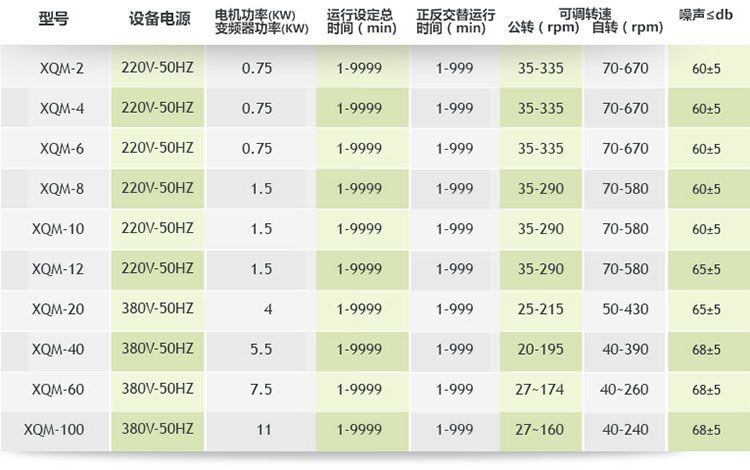

Specifications

XQM-60

XQM-60