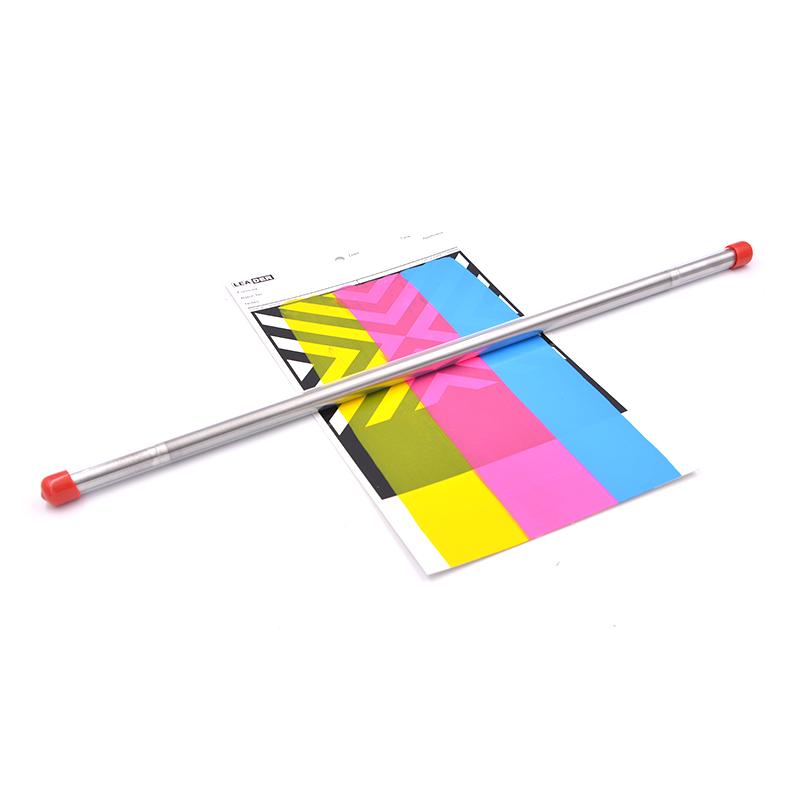

RDS #8 Mayer Rods WFT 18.3μm Length 400mm

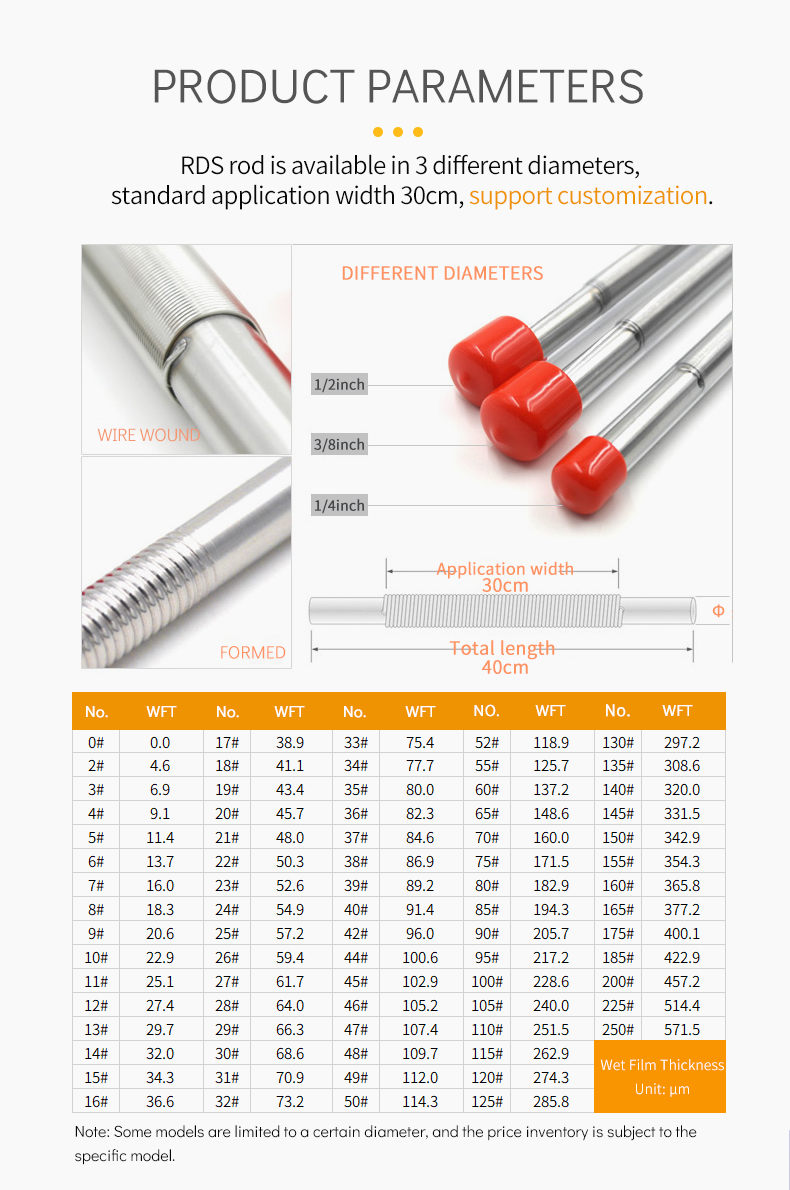

SEWire-wound, wet film thickness 18.3μm, diameter 9.52mm, Total length 400mm, Spreader width 300mm, material stainless steel, Wire diameter 0.20mm.

$162.00/piece

PromotionLoading...

Coupon

Model:

Similar products

RDS 8# 3/8" Applicator rod 3/8 "SPEC

RDS 8# 3/8" Applicator rod 3/8 "Details

RDS 8# 3/8" Applicator rod 3/8 "Packing list

- SKU

- NB000006

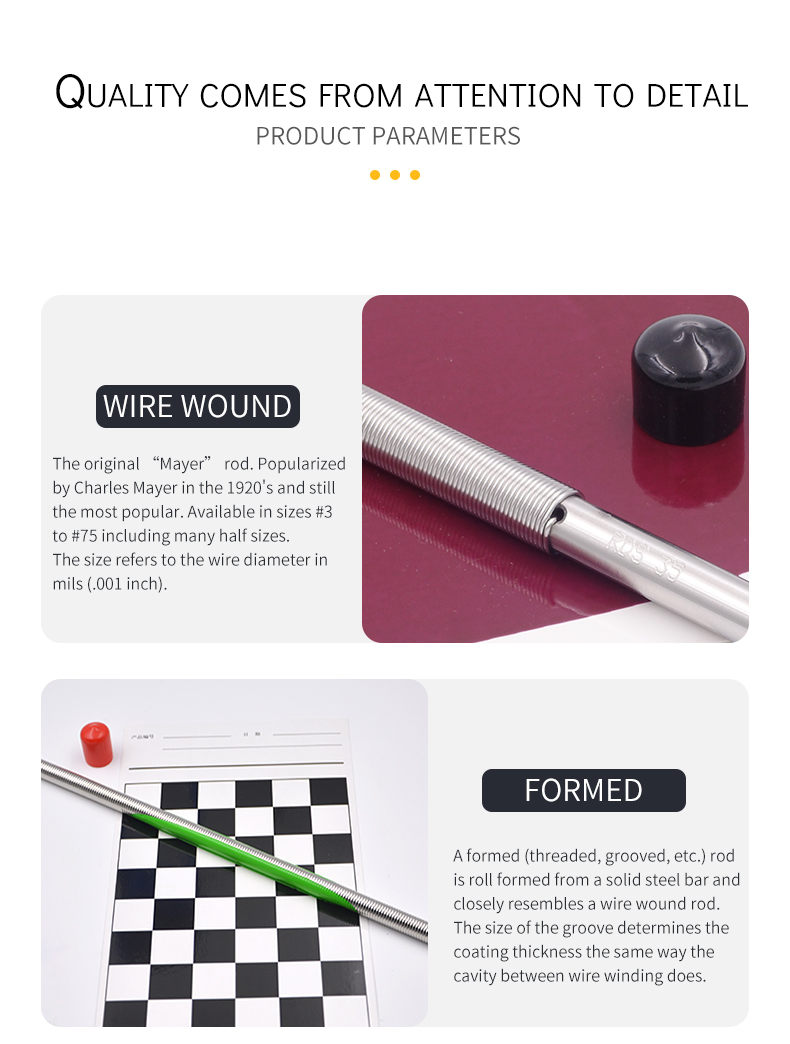

- Production process

- wire-wound

- WFT

- 18.3μm

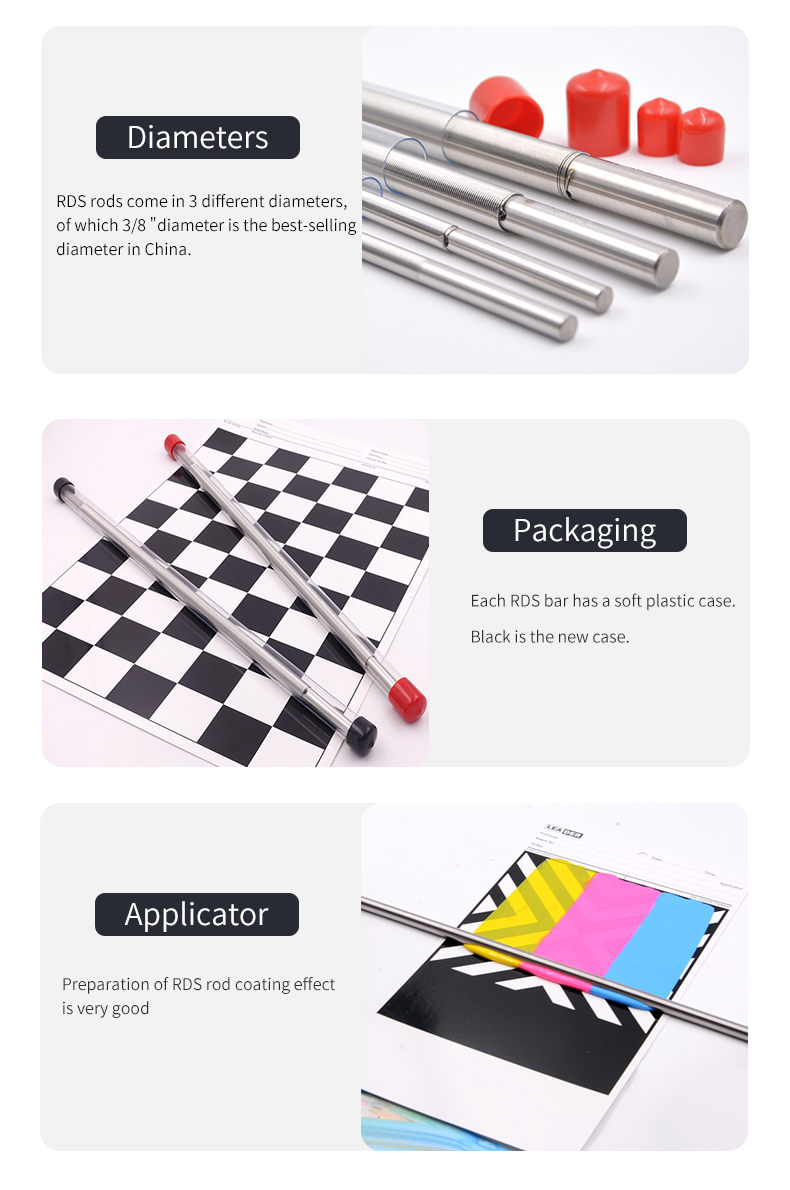

- diameter

- 9.52mm

- Total length

- 400mm

- application width

- 300mm

- Grip Width

- 50+50mm

- material

- stainless steel

- Wire diameter

- 0.20mm

8# 3/8"

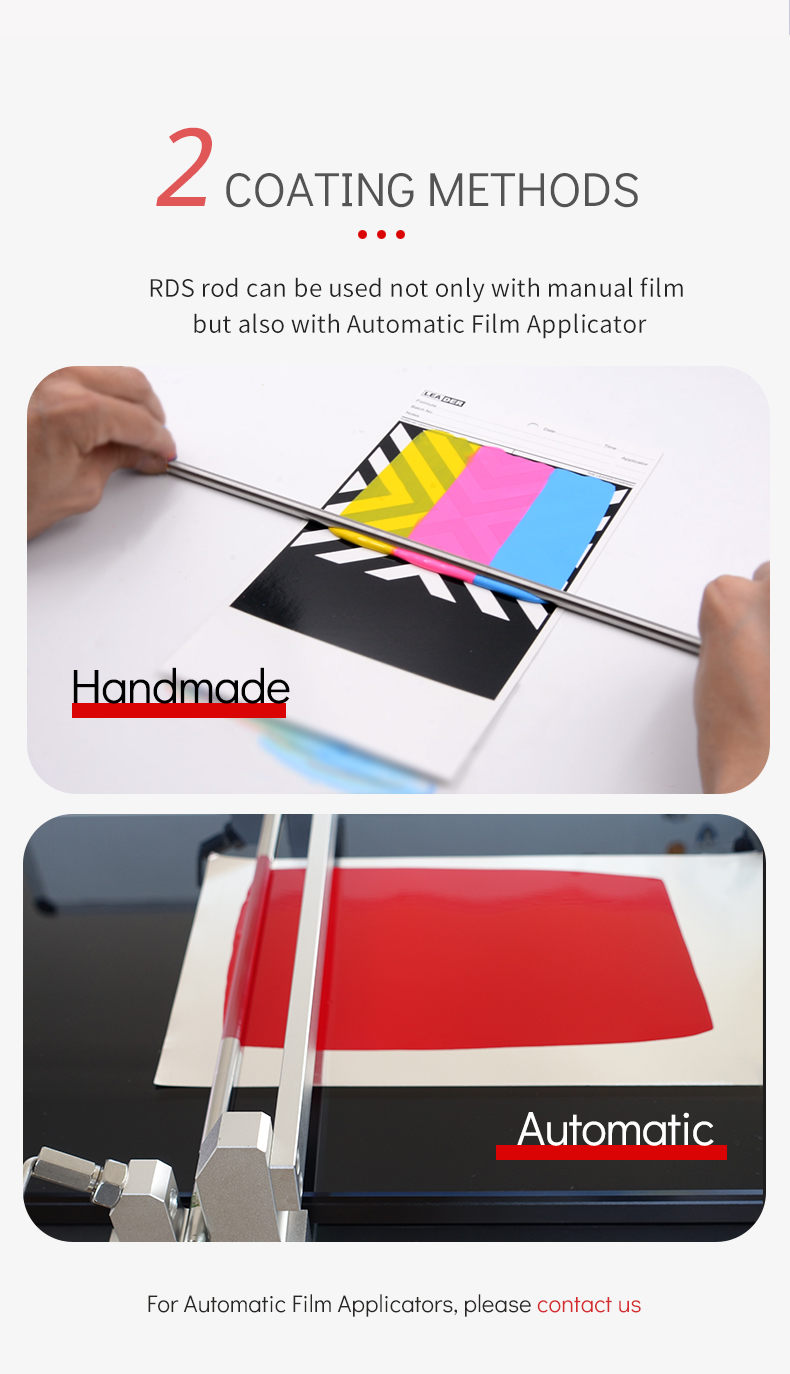

Applicator rod 3/8 "

Wire-wound, wet film thickness 18.3μm, diameter 9.52mm, Total length 400mm, Spreader width 300mm, material stainless steel, Wire diameter 0.20mm.

FAQ

QHelp recommend the wire rod: Solid content is about 50%, powder pulp, generally very thin, is No. 8 rod okay?

A

The wet film thickness of RDS8 rod is 18.3μm.

QHow long does it usually take to replace the wire rod?

A

Wire rod replacement mainly depends on your Frequency of use and maintenance, Miscellaneous users have half a year to a year.

QHow thick is the No. 8 coating bar of RDS than the No. 6 film?

A

The wet film thickness of No. 6 rod is 13.7 μm, and the wet film thickness of No. 8 rod is 18.3 μm.

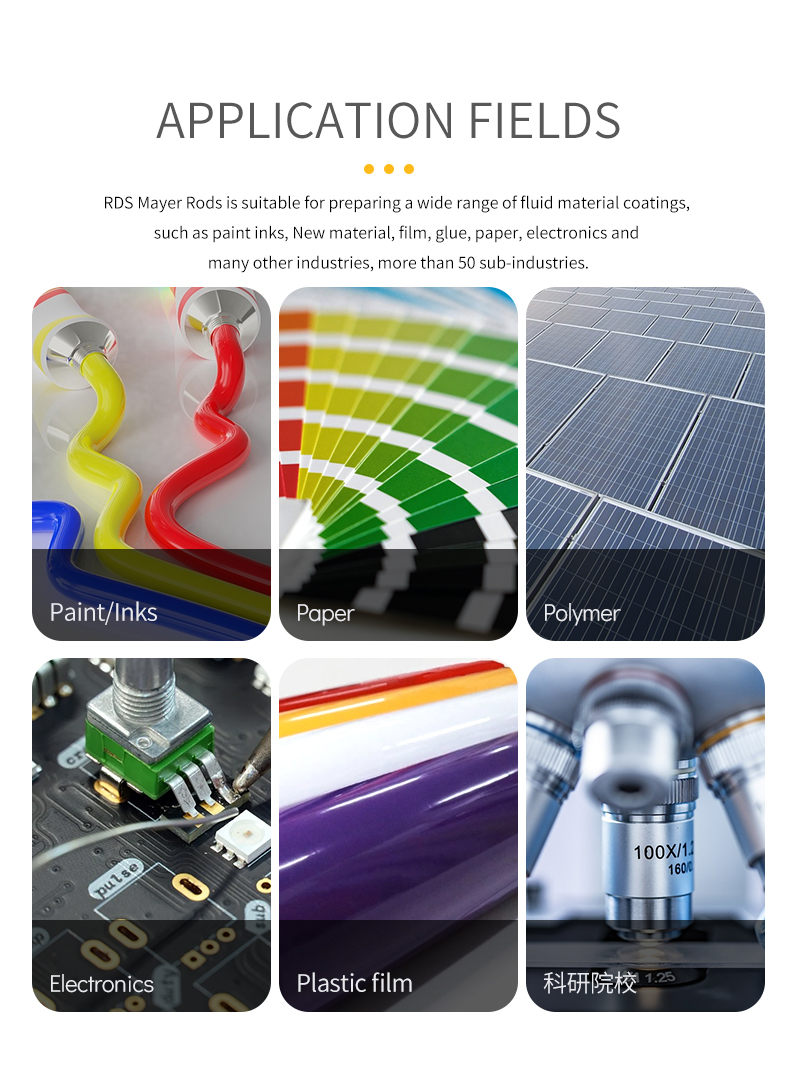

QWhat is the purpose of Mayer Rods 8?

A

Wire rod film applicator is based on wet film thickness, please convert to wet film thickness microns first.

QWhich micron Wire-wound drawdown bar is used for general oily inks?

A

I don't know, but most people go for the small bar.

QI would like to ask if there is a Spreader with a moisture content between 15-20g, and which model of RDS should I use?

35-40% dry weight is about 6g.

A

40% solid content, wet film thickness 16 microns If you press 35% solid content, use wet film thickness 18 microns

Just 7 and 8.

QI scrape 18um film, which type of wire stick should I buy?

A

Hello, use the RDS8 stick.

QI would like to ask if there is a Spreader with a moisture content between 15-20g, and which model of RDS should I use?

A

Hello, 40% solid content, wet film thickness 16 microns, if you press 35% solid content, use wet film thickness 18 microns, on No. 7 and No. 8.

QWire bar coater, wet film thickness 15-25μm, length 400mm or more, which model of RDS is suitable?

A

Hello, RDS Mayer Rods No. 8 stick, film Film thickness 18.3μm.

QHello, my American RDS rod 8 #scraper is always silk horizontal, what's the matter?

A

Hello, scratches on the wire rod are related to many factors: Printing ink viscosity, whether there are impurities in Printing ink, operation method, uniformity of scraping force, scraping backing plate, and whether the scraping rod is clear and clean. You can do the following factors to exclude.

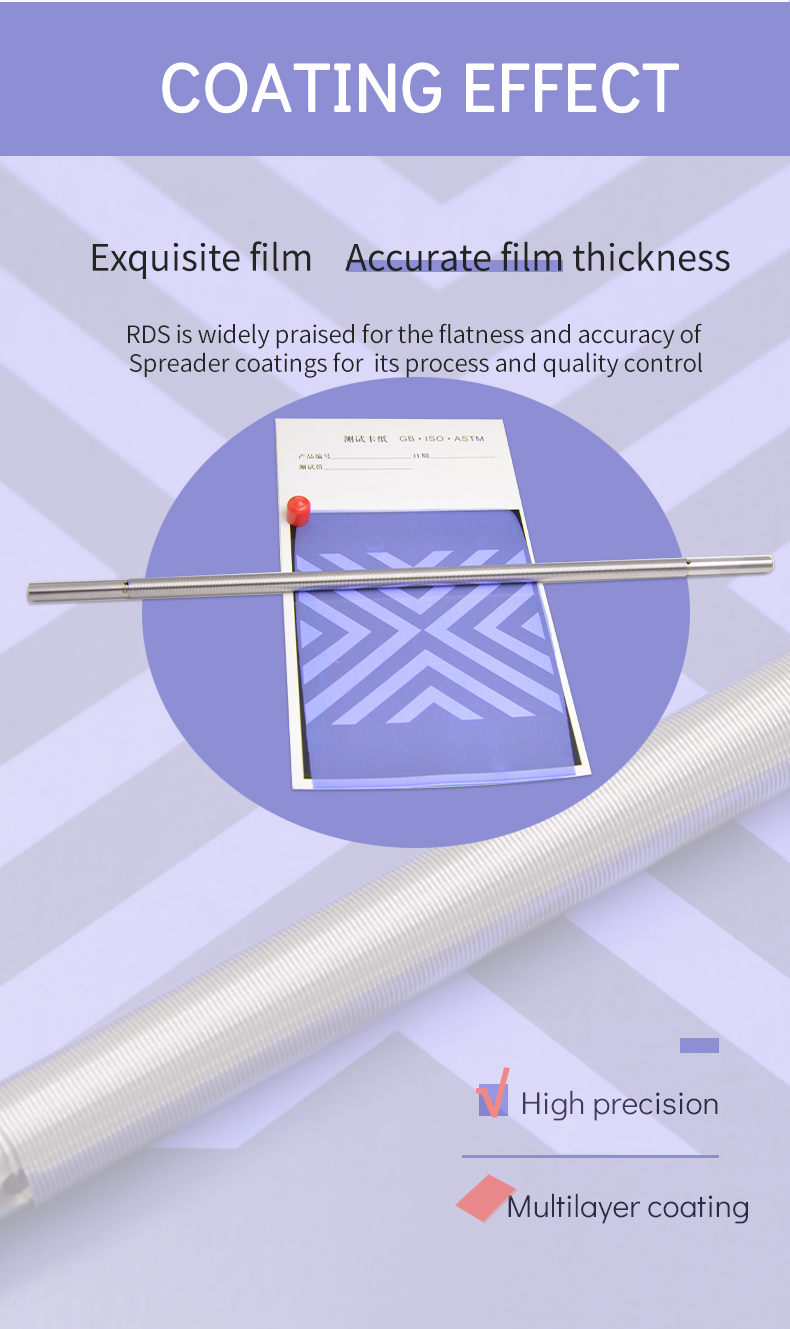

Knowledge

- 1Bar Spreader Technology: Principles, Applications and Advantages over Miscellaneous coating methods

- 2Application of Mayer Rods in protective coating prepative

- 3Application of Mayer Rods in Water-based ink Moulding

- 4Technical method and application of preparing nanometer silver wire thin films with Mayer Rods

Standard

- 1GB/T 1727-2021《General methods for preparation of coating films》

- 2GB/T 7044-2022《Colour carbon black》

- 3HG/T 5370-2018《Waterborne coatings for bicycles》

- 4HG/T 3951-2007《Water based colorants for architectural coatings》

- 5GB/T 13217.1-2020《Test method for colour and tinctorial strength of ink》

- 6HG/T 3948-2007《Hot Melt Adhesives for Sanitary napkin & Panty liner》

- 7ASTM D4147-2023《Standard Practice for Applying Coil Coatings Using Wire-Wound Drawdown Bars》

- 8GB/T 13217.1-2009《Test method for colour of liquid ink》

- 9GB/T 13217.7-2009《Test method for adhesion to substrate of liquid ink with tape》

- 10GB/T 21867.3-2008《Pigments and extenders - Methods of assessment of dispersion characteristics - Part 3:Assessment from the change in gloss》

8# 3/8"

8# 3/8"