MODERNER T-4 coated 4 Viscosity Cup aluminum alloy material

SE-

JINGKELIAN QND-4B Coated 4 Viscometers (Aluminum Cup)$ 132.00SE

JINGKELIAN QND-4B Coated 4 Viscometers (Aluminum Cup)$ 132.00SE -

JINGKELIAN QND-4C Viscosity Cup measurement Coatings, paints and other viscosity Measurement range 10-150s viscosity$ 137.00SE

JINGKELIAN QND-4C Viscosity Cup measurement Coatings, paints and other viscosity Measurement range 10-150s viscosity$ 137.00SE -

JINGKELIAN QND-4A Viscometer (Bakelite Cup) is suitable for measuring viscosity of Coating products under 150 seconds$ 118.00SE

JINGKELIAN QND-4A Viscometer (Bakelite Cup) is suitable for measuring viscosity of Coating products under 150 seconds$ 118.00SE -

JINGKELIAN QND-4D Portable Viscometer GB1723-79 Standard 4mm caliber for Coatings, paints viscosity measurement$ 129.00SE

JINGKELIAN QND-4D Portable Viscometer GB1723-79 Standard 4mm caliber for Coatings, paints viscosity measurement$ 129.00SE -

JFL QND-4 coated four cups$ 128.00SE

JFL QND-4 coated four cups$ 128.00SE

Moderner T-4 Viscosity CupSPEC

Moderner T-4 Viscosity CupDetails

Moderner T-4 Viscosity CupPacking list

- SKU

- NB000618

- outflow time

- 30~100s

- flow hole diameter

- 4mm

- Capacity

- 100ml

- Cup body material

- aluminum alloy

- Filter material

- stainless steel

- Handle material

- aluminum alloy

- Applicable standard

- GB/T 1723

- Environmental temperature

- 25±2℃

- Certificate

- none

- Correction factor

- 0.97~1.03

- Inner cone angle

- 81°

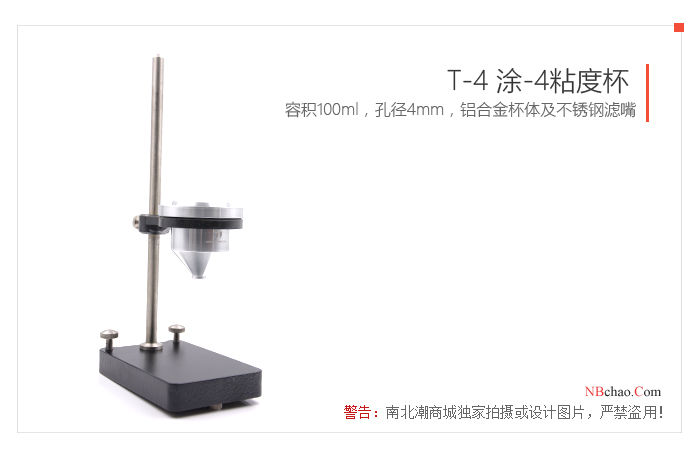

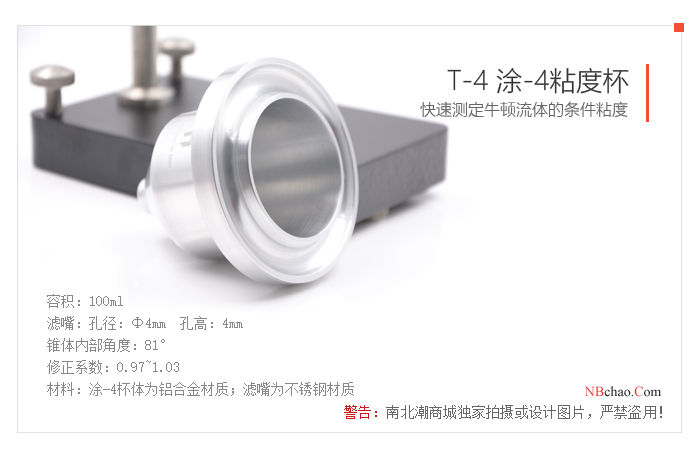

T-4 Viscosity Cup is a coating 4 Viscosity Cup developed by MODERNER according to the standard. The volume of the cup is 100ml, the hole diameter is 4mm, the cup body is made of aluminum alloy and the filter is made of stainless steel. It is equipped with a bracket to achieve more stable viscosity measurement.

Applicable scope of T-4 Viscosity Cup

T-4 Viscosity Cup is widely used for viscosity measurement of fluids such as coatings/paints/inks. Tu-4 cup produced in MODERNER is especially suitable for paint manufacturers and users to quickly measure the conditional viscosity of Newtonian fluid or near-Newtonian fluid in the laboratory or workshop.

T-4 Viscosity Cup product map

How to use and maintain

1. Before each measurement, wipe the inside of the sticky T-4 Viscosity Cup with a silk cloth dipped in solvent and dry it. The leak nozzle should be clean when observing the light.

2. Adjust the horizontal screw to make the end face of the T-4 Viscosity Cup level.

3. Place a container under the leak nozzle, block the leak nozzle hole with your hands, slowly fill the sample into the viscometer, slide and push it along the edge of the viscometer with a flat glass, and scrape off the excess sample. Release the finger to let the sample flow out, that is, start the stopwatch, and stop the stopwatch when the sample flow is first interrupted. The total time for the sample to flow out of the T-4 Viscosity Cup is the conditional viscosity of the sample. The difference between the two measured values should be less than 3% of the average value.

4. The temperature of the sample is 25°C±0.5°C during the measurement, and it should be measured in a constant temperature room. If the test is not carried out in a constant temperature room, a thermometer should be placed in the sample stream, and the temperature shown should be kept the same as the temperature before the outflow more than 0.5°C.

5. After the test, the T-4 Viscosity Cup should be wiped clean with solvent and coated with anti-rust oil. Do not use any sharp metal objects when wiping to avoid scratching the surface.

Note: After the T-4 Tu 4 Viscosity Cup has been used for a period of time, it should be calibrated according to the provisions of the national standard GB/T1723-93.

- 1GB/T 17001.3-2025《Anti-counterfeiting printing ink—Part 3:Thermochromic anti-counterfeiting printing ink》

- 2JB/T 3078-2015《Varnishes used for electrical insulation.Silicone impregnating varnishes》

- 3KS A0531-1993《Viscosity of Liquid - Methods of Measurement》

- 4GB/T 1727-2021《General methods for preparation of coating films》

- 5GB/T 17001.6-2022《Anti-counterfeiting printing ink—Part 6:Infrared excitation fluorescence anti-counterfeiting printing ink》

- 6HG/T 5187-2017《Automobile axle spring anticorrosive primer》

- 7HG/T 3369-2003《Micaceous ironoxide phenolic anticorrosive paint》

- 8HG/T 3349-2003《Various colour phenolic enamel》

- 9CY/T 205-2019《Screen printing - Pigment dispersion paste for textile printing process control requirements and test methods》

- 10GB/T 13217.4-2020《Test method for viscosity of ink》

T-4

T-4