qinsun Leather Rub Resistance TesterSPEC

qinsun Leather Rub Resistance TesterDetails

qinsun Leather Rub Resistance TesterPacking list

- SKU

- NB006202

- friction hammer

- Diameter 16mm or 25mm

- Power supply Voltage

- 220V

- Standards

- SatraTM167,BS1006:x12:1990

Standards:

SatraTM167,BS1006:x12:1990

Scope of application:

The instrument is used to detect the dry/wet friction friction decolorization test of leather, and is also suitable for the color fastness test of colored fabrics such as cotton, chemical fiber, and blend.

Product Details:

This Tester is used to determine the color fastness that may occur from the stained surface to other surfaces due to friction. The machine gets its name from the term "friction decolorization", which refers to the transfer of pigments or other substances from the test piece to a dry/wet cloth that rubs against each other.

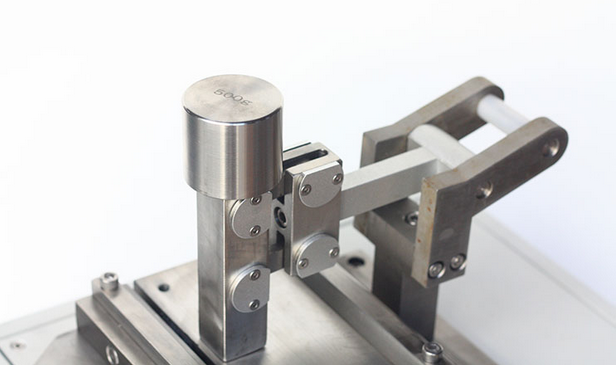

The machine consists of a base plate on which a specimen to be tested is fixed. The test head can be moved back and forth along the specimen. The standard friction cloth is installed on the test head, and the movement of the test head is controlled by the crankshaft transmission of the handle, and a certain load is applied to the test head during the movement. Dyed leather is usually tested with a white bleached fabric and a black cloth that does not fade for white leather. In the test, one revolution per second, usually 10 revolutions to complete the entire test. Color transfer was assessed using a grayscale scale.

Features

It is used for dry and wet friction decolorization tests of leather, suitable for recurrent or periodic tests.

A. Friction head diameter: 16mm or 25mm;

B. The supply pressure is: 9N;

C. Electric drive, need working Voltage 220V;

D. Equipped with an electronic counter, it completely simulates the test results of ten times of manual friction, and the data is highly reproducible;

E. Fixtures equipped with standard friction fabrics;

F. The specimen clamp spring is made of steel to ensure that the specimen is fastened quickly;

G. Equipment control mode: AATCC, ISO and other standards are set internally, and you can also set the program by yourself;

H. It has the function of automatic alarm after the test is completed.

The leather friction decolorization testing machine is suitable for testing the damage and decolorization degree of dyed leather, textile and other materials after friction.

Procedure:

1. Place the air-conditioned specimen on the test bench and stretch it by 10% in the direction of friction.

If the specimen cannot be elongated by 10%, stretch the specimen to a better allowable elongation.

b. If the specimen cannot be kept stable during friction after 10% elongation, continue to stretch the specimen until the specimen cannot be elongated.

(Note: Record the elongation of the specimen in the test report)

2. Test the general leather sample, load the load block, so that the total weight of the test head is 1000g. Suede and similar leathers (including frontal garment leather), due to the influence of large friction, do not load the weight block during the test, and the total mass of the test head is 500g.

3. Fix the prepared test felt pad on the test head, so that the test head is in horizontal contact with the leather sample. Select the following friction times: 5, 10, 20, 50, 100, 200, 500.

4. If necessary, replace the test felt pad with a new one, re-select the number of tests, test the untested parts of the sample or a new sample.

5. Remove the sample and felt pad, and evaluate the color change of the leather color and the staining of the felt pad according to the specified gray sample card for the color change of the friction area of the sample and the staining of the felt pad. Record any visible changes in the surface of the specimen (changes in gloss, changes after polish application, changes in fluff, damage to the coating, etc.).

- 1Test method for color fastness

- 2 What are the common equipment for leather physical testing?

- 3What are the two commonly used equipment for leather physical testing?