JINGKELIAN JKCH dual-use Thickness Gauge, suitable for magnetic/nonmagnetic metal substrates, using magnetic and eddy current thickness measurement

JingKeLian JKCH-1250 Dual-use Thickness GaugeSPEC

JingKeLian JKCH-1250 Dual-use Thickness GaugeDetails

JingKeLian JKCH-1250 Dual-use Thickness GaugePacking list

- SKU

- NB000626

- Principle of thickness measurement

- Magnetic Induction and eddy Current

- Indication Accuracy

- +/- [ (1%~ 3%) H + 1um] (Note: H is the thickness reading)

- matrix thickness

- Minimum thickness: 0.2mm; Minimum measurement surface: 15mm

- Power Supply

- 4 AAA batteries (if not used for a long time, please remove the battery)

- Weight

- 82G (without battery)

- Dimensions

- 112×69×28mm

Overview of JKCH dual-purpose Thickness Gauge

JKCH magnetic and non-magnetic dual-purpose Thickness Gauge adopts magnetic and eddy current thickness measurement methods, which can non-destructively measure the thickness of non-magnetic coatings (such as aluminum, chromium, etc.) on magnetic metal substrates (such as steel, iron, alloys and hard magnetic steel, etc.) , copper, enamel, rubber, paint, etc.) and the thickness of the non-conductive covering layer on the non-magnetic metal substrate (such as copper, aluminum, zinc, tin, etc.) (such as enamel, rubber, paint, plastic, etc.)

Features and applications

The magnetic and non-magnetic dual-purpose Thickness Gauge has the characteristics of small measurement error, high reliability, good stability and easy operation. It is a testing instrument required to control and ensure product quality. It is widely used in manufacturing, metal processing industry, chemical industry and so on. Industrial, commodity inspection and other testing fields.

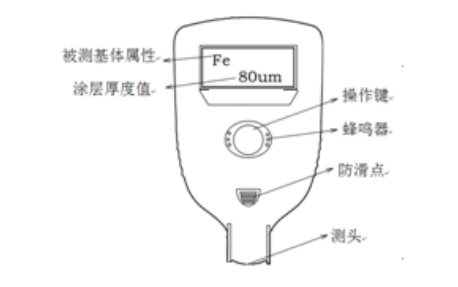

JKCH dual-purpose Thickness Gauge structure diagram

- 1GB/T 44757-2024《Anodizing coating on titanium and titanium alloys》

- 2QJ 990.3A-2011《Inspection methods of coating.Part 3:Measurement of coating thickness》

- 3ASTM B244-2021《Standard Test Method for Measurement of Thickness of Anodic Coatings on Aluminum and of Other Nonconductive Coatings on Nonmagnetic Basis Metals with Eddy-Current Instruments》

- 4ASTM B499-2021《Standard Test Method for Measurement of Coating Thicknesses by the Magnetic Method: Nonmagnetic Coatings on Magnetic Basis Metals》

- 5 B530-2014《》

- 6ISO 2360-2017《Non-conductive coatings on non-magnetic electrically conductive base metals — Measurement of coating thickness — Amplitude-sensitive eddy-current method》

- 7ISO 2178-2016《Non-magnetic coatings on magnetic substrates — Measurement of coating thickness — Magnetic method》

- 8ASTM D7091-2022《Standard Practice for Nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied to Ferrous Metals and Nonmagnetic, Nonconductive Coatings Applied to Non-Ferrous Metals》

- 9ASTM B499-2021《Standard Test Method for Measurement of Coating Thicknesses by the Magnetic Method: Nonmagnetic Coatings on Magnetic Basis Metals》

- 10ISO 19840-2012《Paints and varnishes Corrosion protection of steel structures by protective paint systems》