JINGKELIAN QGZ-6 12 24 Film Drying Time Recorder Scribing radius: 0.25/0 5/1.0/1.5mm

SEJingKeLian QGZ-6 12 24 Drying Time RecorderSPEC

JingKeLian QGZ-6 12 24 Drying Time RecorderDetails

JingKeLian QGZ-6 12 24 Drying Time RecorderPacking list

- SKU

- NB000630

- Number of strokes

- 4 stitches

- Scratch Specifications

- R 0.25/0.5/1.0/1.5mm

- itinerary

- F100mm

- trajectory period

- 6/12/24h/T

- Execution standards

- GB/T1728-79

- Measurement error

- ±0.5%

Application of paint film drying time Tester

QGZ-(6, 12, 24) paint film drying time Tester is a new type of instrument for measuring paint drying time. For the coating film formed by various paints, it can automatically and continuously display the state of each stage of the drying process in the form of drawing a circular trajectory, and can intuitively analyze and observe the time spent in each stage. It is a satisfactory instrument for paint testing and paint formulation research.

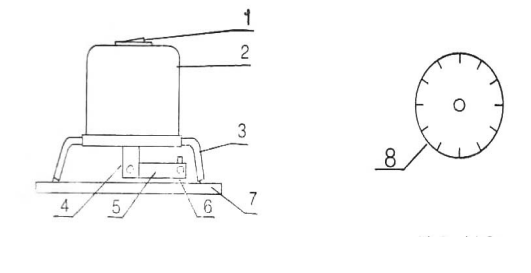

Structure of QGZ-6 12 24 paint film drying time Tester

It consists of a switch (1), an outer cover (2), a motor (inside the cover), a foot (3), a connecting shaft (4), a rotating arm (5), a marking needle (6), a test plate (7), and a time dial (8) Composition.

Requirements for the use of automatic paint film drying time Tester

1. Test plate: glass plate (200*200*2~3). Or smooth tin plate (200*200*0.2~0.3) or agreed test plate material.

2. Test environment: According to the requirements of GB1727-79, the coated test panel is placed horizontally, away from airflow and direct sunlight, and the drying test is carried out at a temperature of 25±1°C and a Relative Humidity of 65±5%. Carry out the drying test according to other agreed conditions.

Principle of Paint Film Drying Time Meter

Place the paint film drying time Tester on the prepared coating film test plate, turn on the power supply, synchronize the motor, and drive the rotating arm (5) equipped with the scribing needle (6) through the connecting shaft (4). (The rotating arm is in a free-falling state) Rotate at a constant speed at a speed of one cycle/6 hours, one cycle/12 hours, one cycle/24 hours, and the scribing needle will draw a circular track with a diameter of 100mm on the coating film. As the coating film dries gradually over time, the plow mark on the coating film that the needle scratches changes from wide to narrow, from deep to shallow, until finally no trace can be drawn, thus showing the whole process of drying.

- 1ASTM D5895《Standard Test Methods for Evaluating Drying or Curing During Film Formation of Organic Coatings Using Mechanical Recorders》

- 2ISO 9117-4《Paints and varnishes - Drying tests - Part 4: Test using a mechanical recorder》

- 3DIN EN ISO 9117《Paints and varnishes - Drying tests - Part 4: Test using a mechanical recorder (ISO 9117-4:2012)》

- 4HG/T 5173-2017《Waterborne primer for application on rusty substrates》

- 5JG/T 210-2018《Primer for interior and exterior wall》

- 6JC/T 975-2005《Waterproofing coatings for concrete bridge and road surface》

- 7JG/T 298-2010《Putty for interior》

- 8JC/T 2090-2011《Polymer modified cement slurry for waterproof》

- 9ASTM 《Standard Specification for Aluminum Particle-Filled Basecoat/Organic or Inorganic Topcoat, Corrosion Protective Coatings for Fasteners》

- 10JT/T 821.1-2011《Anti-corrosive coatings for concrete bridge surface.Part 1: Solvent based coatings》

QGZ-6 12 24

QGZ-6 12 24