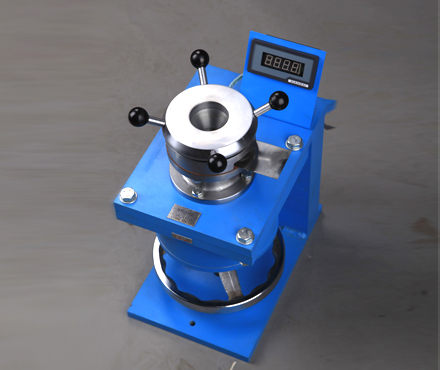

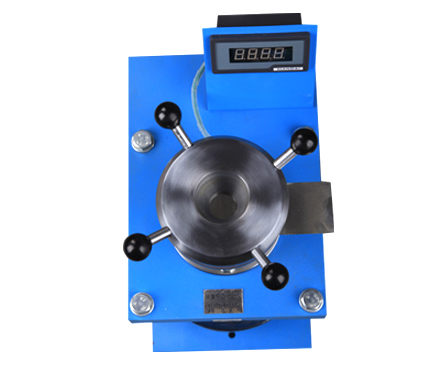

MODERNER TCB Dry-Film anti-cracking performance of Paints, varnishes or related products

Moderner TCB cupping deviceSPEC

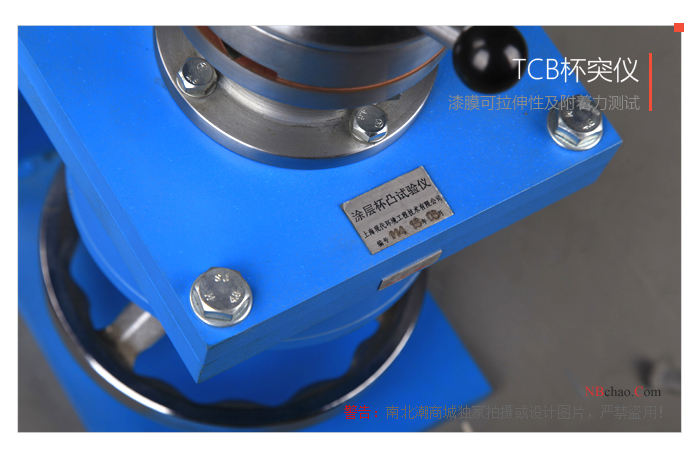

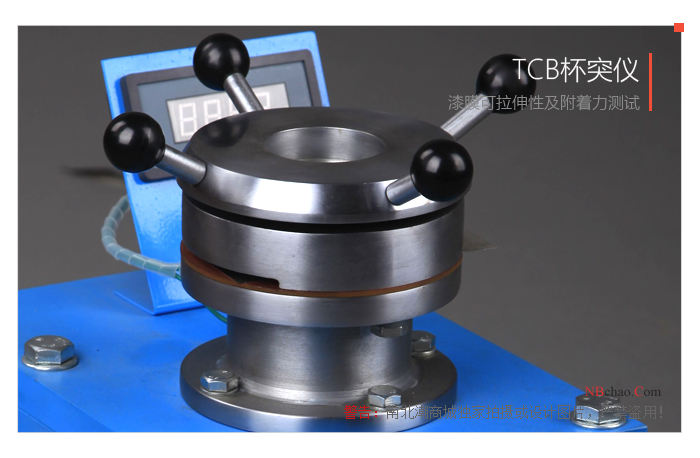

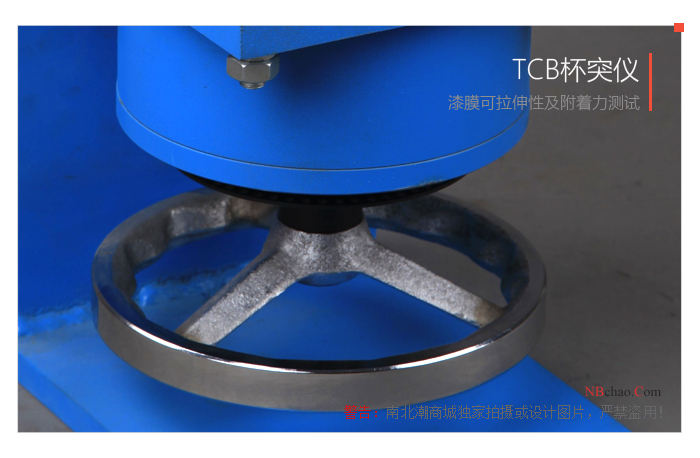

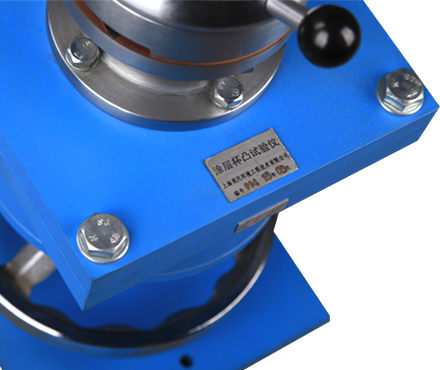

Moderner TCB cupping deviceDetails

Moderner TCB cupping devicePacking list

- SKU

- NB000634

- Striker Diameter

- Φ20mm

- Impression Accuracy

- ±0.05mm

- Maximum depth of indentation

- 10mm

- Digital resolution

- 0.01mm

- Test board size

- 70*70mm

- Standards

- ISO1520, GB9753 standards

- plate thickness

- δ =0.30-1.25mm

Introduction

Cupping Tester, also known as coating cupping Tester, can be used to determine the stretchability or adhesion of paint films. It is designed and manufactured in strict accordance with the ISO 1520 "Paints and Varnishes - Cupping Test" GB9753 standard for MODERNERs. The cupping Tester mainly evaluates the resistance to cracking or separation from the metal substrate of coatings of paints, varnishes and related products after they are gradually deformed under standard conditions. Conduct the test according to the specified indentation depth and evaluate whether it passes or fails. The depth of indentation can be gradually increased to determine the minimum depth at which the coating first appears to crack or begins to separate from the underlying material. The measured data will be displayed on the LCD of the cupping instrument, and the indentation accuracy reaches 0.05.

product picture

Test procedures and methods of use

1. Test panel preparation: Dry the coated test panel according to the drying conditions and drying time specified in the sample standard, and then condition it at a temperature of 23±2℃ and a Relative Humidity of (50±5)% for at least It can be put into testing within 16 hours (except for special provisions).

Note: If the test panel is coated, it can only be sprayed on one side. The back side needs to be conductive and polished with 0# sandpaper before cleaning.

2. Ambient temperature: The test should be conducted in an environment with a temperature of 23±5℃ and a Relative Humidity of (50±5)% (except for special regulations).

3. How to use:

(1) Turn the handwheel of the cupping instrument in the "down" direction (clockwise) to the end, loosen the upper test plate pressing head of the testing machine, insert the test plate with the coated side up into the gap, and connect the punching head and Align the center of the test plate, tighten the test plate clamping head, and firmly fix the test plate on the stamping die.

(2) Turn on the power switch on the rear panel of the device, and 00.00 should be displayed on the display.

(3) Rotate the handwheel in the "up" direction (counterclockwise) to raise the punch head. When the rotation is close to 3 turns, you should slow down and rotate at a speed of about 3 seconds. When the stamping head first contacts the sample, the counter conducts electricity and starts counting, and the counter reading machine is the indentation depth.

(4) Continue to rotate the handwheel until the specified depth is reached, and observe the test plate to determine whether the sample is qualified; you can also gradually increase the indentation depth to determine the minimum depth when the coating first cracks or begins to separate from the base material.

4. Things to note during the test:

(1) During the indentation process, reverse rotation is not allowed, otherwise the counting will be inaccurate.

(2) Use corrected normal vision or a magnifying glass with permission to check whether the coating of the test plate is cracked or separated from the substrate. If a magnifying glass is used, this should be stated in the test report to avoid misunderstandings with visual inspection results.

(3) When measuring the minimum depth that causes damage, when the coating surface cracks or separates from the substrate for the first time, stop rotating the handwheel, read the depth of indentation (accurate to 0.1mm), and repeat the test. to verify the results until the results are consistent.

TCB

TCB