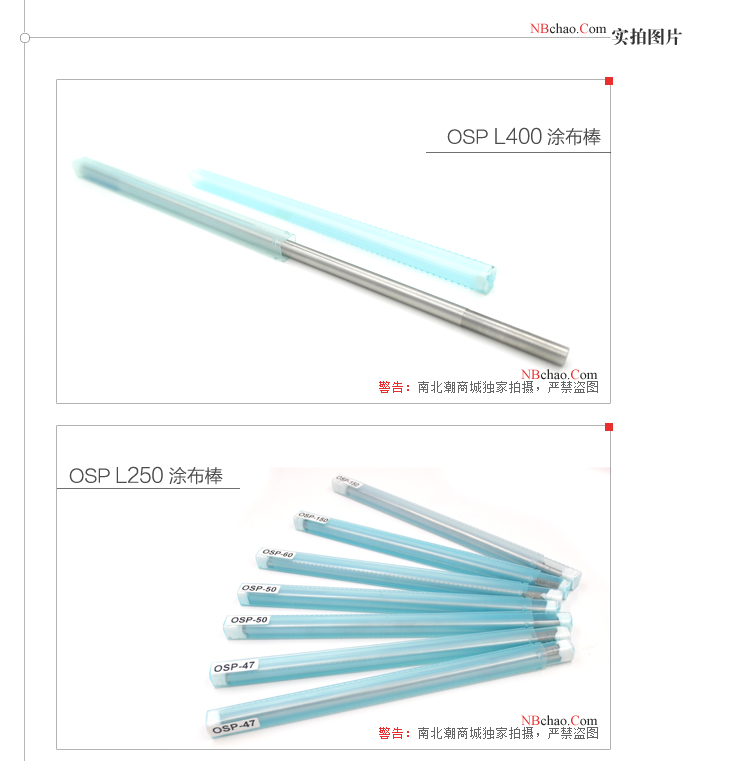

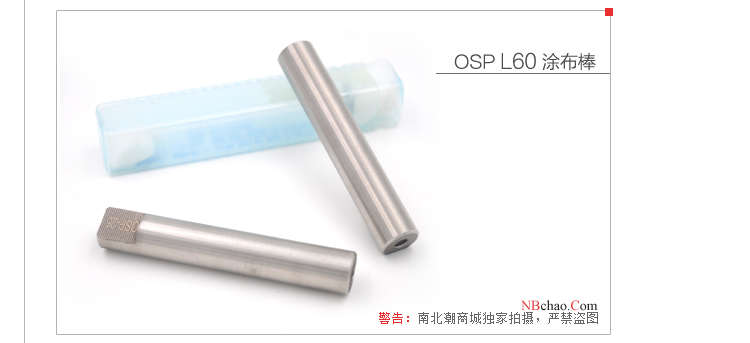

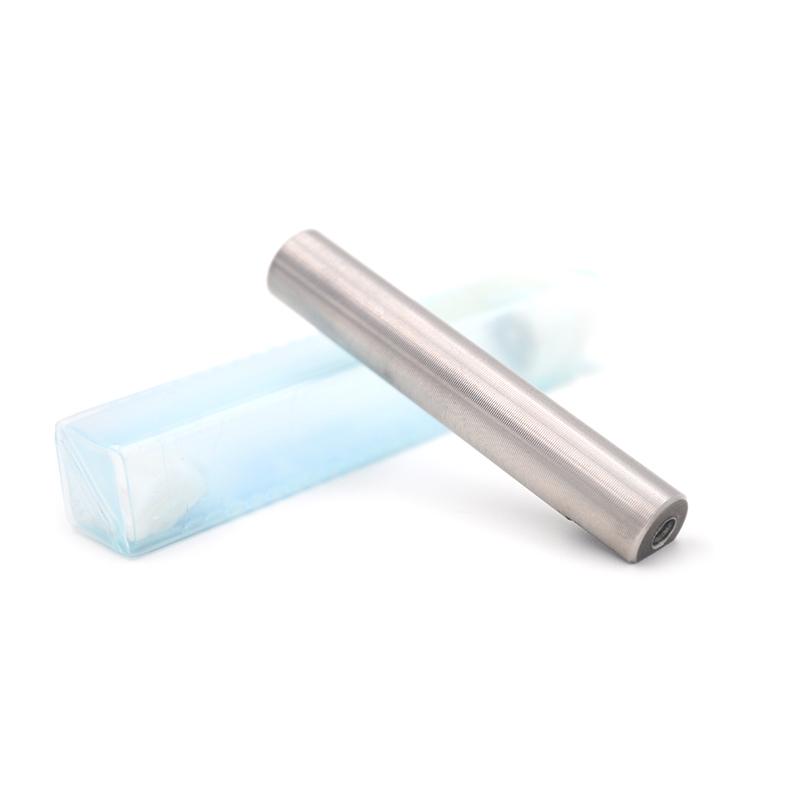

Japan OSP-10/60 stainless steel bar WFT 10μm length 60mm

SEFormed, wet film thickness 10μm, diameter 10mm, Total length 60mm, application width 60mm, grip width 0, material 304 stainless steel.

$116.00/piece

PromotionLoading...

Coupon

Model:

Similar products

OSP OSP-10/60 coating rodSPEC

OSP OSP-10/60 coating rodDetails

OSP OSP-10/60 coating rodPacking list

- SKU

- NB000065

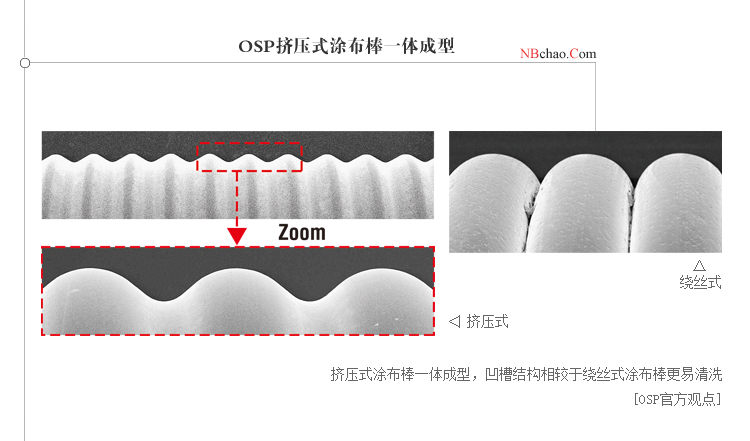

- Production process

- Formed

- WFT

- 10µm

- diameter

- 10mm

- Total length

- 60mm

- Application width

- 60mm

- Grip width

- 0

- material

- 304 stainless steel

OSP-10/60

coating rod

Formed, wet film thickness 10μm, diameter 10mm, Total length 60mm, application width 60mm, grip width 0, material 304 stainless steel.

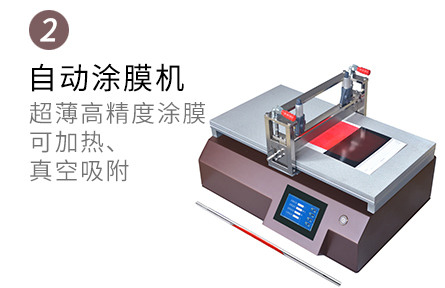

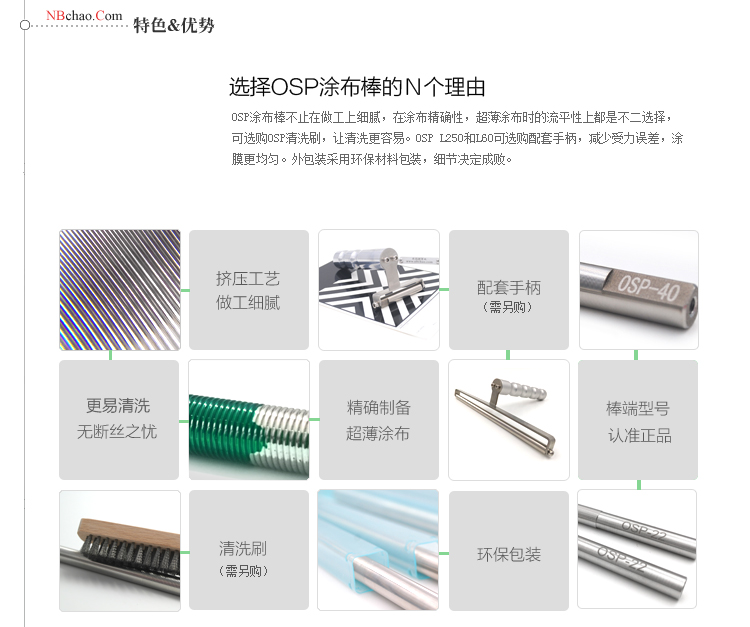

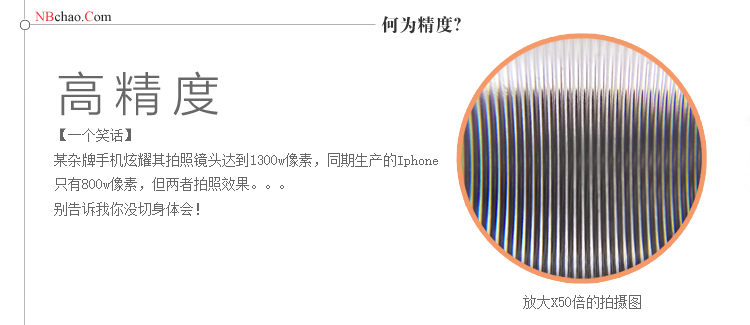

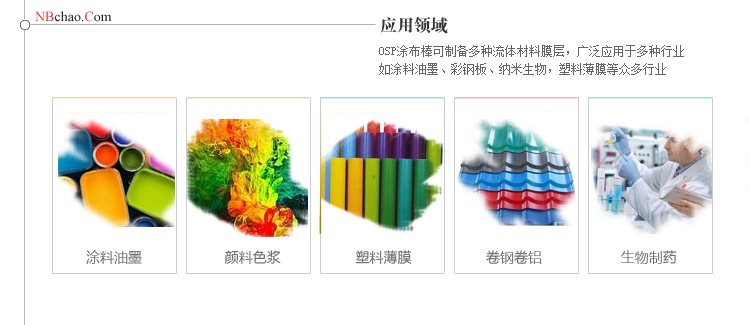

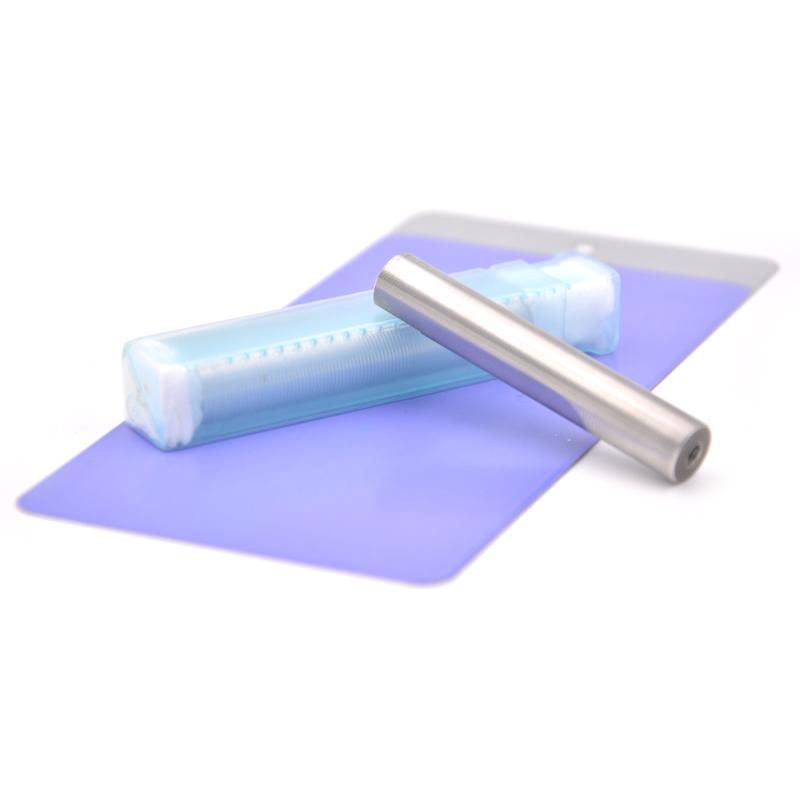

Japan's OSP stainless steel wire rod is an extruded coating rod imported from Japan. It is very popular among users in Japan and South Korea. It is also gradually favored by users in CHINA due to its advantages of easy cleaning and uninterrupted wire. It goes deep into all walks of life and is used for coating wet films with specific thicknesses, for measuring hiding power, color correction and color matching, etc., and OSP stainless steel wire rods also provide customized services, which can be customized to produce rods. OSP-10 stainless steel wire rod can be coated with a wet film thickness of 10 microns.

Optional

| |

|  |

Note: Click on the accessory picture to view Details.

FAQ

QI want to apply a 10 micron thick film on Conductive Glass, which one should I buy? Conductive Glass is very narrow by 1-2 cm.

A

Hello, this wire rod needs a handle.

QDo you have a scraper with a wet film thickness of 10 microns and a length of 60mm?

A

Hello, the Japanese OSP-10/60 model is Spreader width 60mm, film Film thickness 10μm.

QCan this coating rod be prepative of multi-layer ultra-thin film?

A

The wire rod can be prepared for 1.5 micron ultra-thin film. Everyone must know it, but another advantage of it is multi-layer film, which is much better than I-shaped film applicator. But multi-layer film tests the flatness of the previous layers of film drying. Generally, the film thickness (such as less than 10 microns/layer) is too thin to control. The wire rod with Film Applicator is a very good solution, eliminating the problem of uneven pressure and speed of hand scraping.

QDo you have the Mayer Rods involved in GB/T26461?

A

The OSP-10/60 Mayer Rods will do

QIs it feasible to prepare PTFE/PP composite diaphragm with Mayer-Rod?

A

Yes, by diluting to a reasonable PTFE emulsion, Stir a suitable binder uniformly, a single-layer film is prepared on the PP film, and after the composite diaphragm is initially dried, it is placed in a 60 ° C constant temperature bellows for drying, and the solvent evaporates. It is worth PTFE/PP composite diaphragm.

QSpreader and swirl/spin film, pull film what is the difference? Which is good?

A

Swirl/spin film coating can not cover the surface of the substrate Glass, Coating is thrown out of the filamentous film and uneven; pull film uniformity is good, Glass substrate on both sides, transparency is general, film thickness is not easy to control; Spreader Glass surface uniformly covered, good transparency, Coating less, and can control the film thickness well.

QWhat kind of scraper stick can be used for anodized aluminum film 10 microns?

A

This model applies

Knowledge

- 1Bar Spreader Technology: Principles, Applications and Advantages over Miscellaneous coating methods

Standard

- 1GB/T 1727-2021《General methods for preparation of coating films》

- 2HG/T 5370-2018《Waterborne coatings for bicycles》

- 3HG/T 3951-2007《Water based colorants for architectural coatings》

- 4GB/T 13217.1-2020《Test method for colour and tinctorial strength of ink》

- 5GB/T 13217.7-2009《Test method for adhesion to substrate of liquid ink with tape》

- 6GB/T 26461-2011《Gravure ink for paper》

- 7ASTM D823-2018《Paints, varnishes and related products of uniform thickness on the test board》

OSP-10/60

OSP-10/60