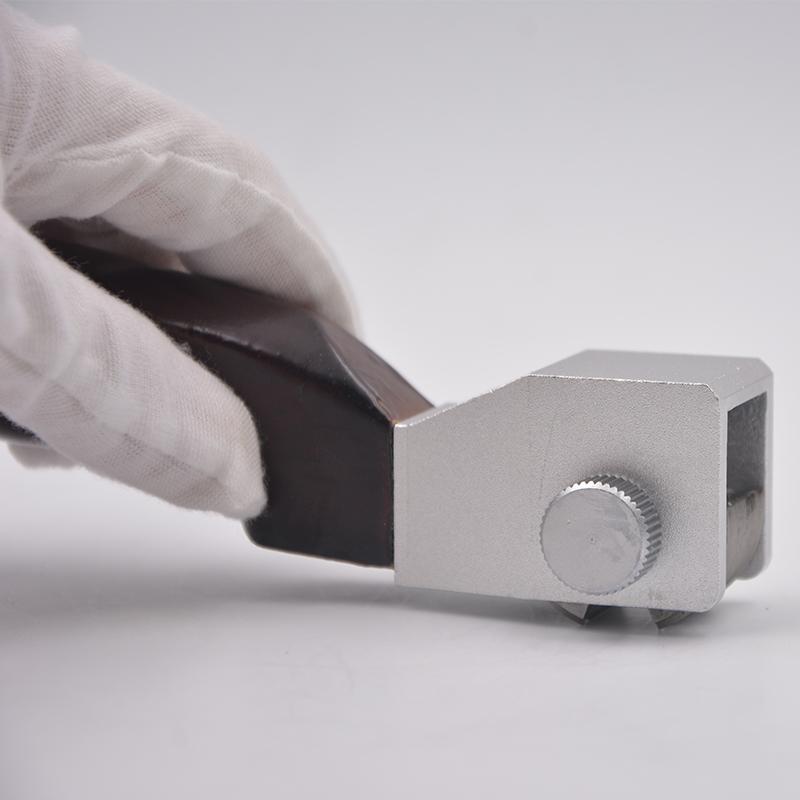

Pushen HGQ 1 * 5 Multi-blade Cross Hatch Cutter Suitable for hard substrates less than 60μm

SEPushen HGQ 1 * 5 Cross Hatch CutterSPEC

Pushen HGQ 1 * 5 Cross Hatch CutterDetails

Pushen HGQ 1 * 5 Cross Hatch CutterPacking list

- SKU

- NB000652

- Number of teeth

- 6 teeth

- Tooth spacing

- 1mm

- application standard

- ISO 2409、ASTM D 3359

- Applicable film thickness environment

- 0 to 60 µm (solid substrate)

The main parameters

Model: 1mm*25 grid (tooth spacing 1mm, number of teeth 6)

Application: hard substrate test piece less than 60μm

Packing: 1 cross grid, 1 roll of 3M adhesive tape, 1 brush, 1 magnifying glass, 1 packing box

application principle

The cross-cutting device, also known as the hundred grid knife, is used to evenly draw a square of a certain size, and evaluate the adhesion of the coating film to the substrate by evaluating the integrity of the coating film in the square.

Applications

The cross-hatching device is used for the determination of the adhesion of the coating cross-hatch method, not only for the laboratory, but also for the construction site under various conditions.

The cross-hatcher complies with the relevant standards of ISO 2409 and ASTM D 3359, and is also applicable to GB/T 9286 "Cross-cut Determination of Paint and Varnish Films"

Relevant test standard requirements

The cross-hatch with 1mm spacing is suitable for hard substrate test pieces with paint film thickness less than 60μm.

The 1.5mm-spaced cross-hatch is suitable for hard substrate test pieces with a paint film thickness of 30 to 90 μm.

The cross-hatch with 2mm spacing is suitable for hard substrate test pieces with a paint film thickness of 60 to 120 μm.

The cross-hatch with 3mm spacing is suitable for hard substrate test pieces with paint film thickness greater than 120μm.

model information

Multi-bladed crosshatcher:

HGQ 1mm*25 grid (tooth spacing 1mm, number of teeth 6)

HGQ 1mm*100 grid (tooth spacing 1mm, number of teeth 11)

HGQ 2mm*25 grid (tooth spacing 2mm, number of teeth 6)

HGQ 2mm*100 grid (tooth spacing 2mm, 11 teeth)

HGQ 3mm*25 grid (tooth spacing 3mm, number of teeth 6)

- 1JJF 2163-2024《Calibration Specification for Paint Film Scribers》

- 2SJ 20910A-2018《General specification for powder spraying coating》

- 3SY/T 4106-2016《Specification of solvent - free polyurethane coatings for steel pipelines and tanks》

- 4 002-2017《Water based polyurethane coatings》

- 5GB 10810.4-2012《Uncut finished spectacle lenses - Part 4: Specifications and test methods for anti-reflective coatings》

- 6GB/T 13217.7-2023《Test method for adhesion to substrate of ink with tape》

- 7GB/T 4893.4-2023《Test of surface coating of furniture—Part 4:Determination of adhesion by cross-cut》

- 8GB/T 42541-2023《Coated steel pipes for gas piping》

- 9GB/T 13448-2019《Test methods for prepainted steel sheet and strip》

- 10HG/T 2006-2006《Thermosetting powder coatings》

HGQ 1 * 5

HGQ 1 * 5