JIAHANG JH-1200 chilled down water circulation device, cooling capacity 1200W

JIAHANG JH-1200 Chill down water circulation deviceSPEC

JIAHANG JH-1200 Chill down water circulation deviceDetails

JIAHANG JH-1200 Chill down water circulation devicePacking list

- SKU

- NB006560

- Temperature range

- 5~40℃

- Temperature Fluctuation

- ±0.3℃

- Temperature Resolution

- 0.1℃

- Tank Volume

- 8L

- Temperature control mode

- Combining Hot Gas Bypass and PID

- Circular mode

- Internal/external circulation

- Total Power

- 1200W

- Flow rate of pump

- 20L/min

Description

Jiahang JH-1200 cooling water circulation device adopts non-start-stop refrigeration technology, which is designed and manufactured to provide professional technical indicators and reliability in the industry, and is a high-precision and high-stability cooling equipment; The equipment adopts a fully enclosed refrigeration system, combined with PID temperature control, fast refrigeration, stable temperature, and meets some requirements for precision and constant temperature cooling equipment.

Innovation advantage

1) Adopt electronic expansion valve technology to control temperature, non-compressor start-stop type, reduce the damage to the compressor, and save 20% of electric energy;

2) Automatic detection of high-low water levels, automatic prompting of liquid addition when low a certain value;

3) The imported compressor has low sound and high refrigeration rate.

Features

1. The refrigeration system adopts imported Taikang compressor to ensure the refrigeration capacity and reduce the minimum noise at the same time.

2、PID temperature control technology is adopted. Refrigeration is not a traditional compressor start-stop type, and the use of electronic expansion valve technology greatly improves stability.

3、The refrigeration control system has its own temperature overrun protection and automatic alarm function, which fully prevents the damage of the constant temperature medium caused by low or high temperature value of the bath liquid.

4、With water level observation window and automatic water level detection device, the buzzer will automatically alarm if the water level is too low.

5、The automatic water flow detection device is convenient for automatic switching to internal circulation when the external circulation is blocked.

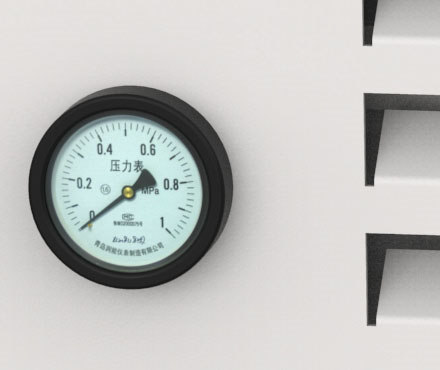

6、High-performance circulating water pump, which can maintain continuous work for a long time, good sealing and no leakage. The Circulating Chiller pressure is 0~1.5par, which can be adjusted by knob and displayed by pressure gauge. Enjoy a more intuitive operating experience.

7、The color LCD screen display shows more data information and dynamic identifiers, so that you can see the running status of the instrument at a glance.

Main application areas

1. Analytical instruments: spectrometer, mass spectrometer, viscometer, polarimeter, fermentation device, rotary evaporator;

2. **: Molecular pump, cryometer, X-ray machine, nuclear magnetic resonance, accelerator;

3. Industrial equipment and others: laser equipment, vacuum coating equipment, biology, molds, machine tools, vacuum furnaces, welding machines, reactors.

- 1GB/T 26808-2011《Thermostatic baths and circulators - Refrigerated baths》

- 2GB/T 18856.4-2008《Test methods for coal water slurry, Part 4: Determination of apparent viscosity》

- 3FZ/T 50010.3-2011《Pulp for viscose fibres, determination of viscosity》

- 4GB 9278-2008《Temperature and Humidity of Coating Specimen State Adjustment and Test》

- 5GB/T 5561-2012《Surface active agents - Determination of viscosity and flow properties using a rotational viscometer》

JH-1200

JH-1200