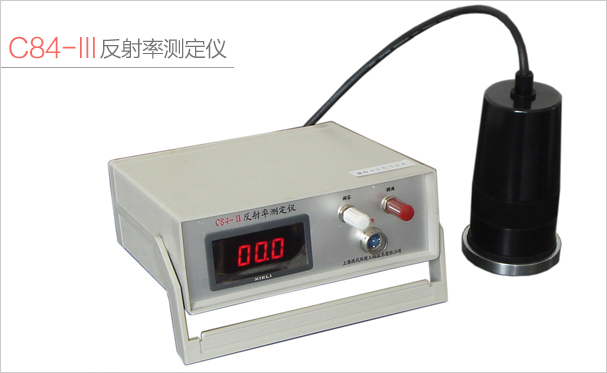

MODERNER C84-III reflectivity meter for white and shallow Paints hiding power measurement and comparison of Coating and Paints

SE-

3NH NR4510 reflectance Tester$ 475.00SE

3NH NR4510 reflectance Tester$ 475.00SE -

PUSHEN Pushen C84-III reflectivity meter$ 616.00SE

PUSHEN Pushen C84-III reflectivity meter$ 616.00SE -

YONGLIDA C84-III desktop reflectivity meter 0~100$ 475.00SE

YONGLIDA C84-III desktop reflectivity meter 0~100$ 475.00SE -

JFL JFL-R Portable reflectance Tester for hiding power of Paints, colorants, etc$ 341.00SE

JFL JFL-R Portable reflectance Tester for hiding power of Paints, colorants, etc$ 341.00SE -

JINGKELIAN C84-III reflectivity meter film hiding power measuring instrument$ 358.00SE

JINGKELIAN C84-III reflectivity meter film hiding power measuring instrument$ 358.00SE

Moderner C84-III reflectivity MeterSPEC

Moderner C84-III reflectivity MeterDetails

Moderner C84-III reflectivity MeterPacking list

- SKU

- NB000658

- Indication interval

- 0~100

- Resolution

- 0.1

- Power Supply

- 220v 50Hz

Introduction

MODERNER C84-III reflectance Tester is mainly used for the determination of the hiding power of white and light paints, and is also commonly used for the comparative test of coatings and paints. The C84-III reflectance Tester complies with international standards ISO 3905, ISO 3906, Chinese standards GB/T 13452, GB 9270, GB 5211.

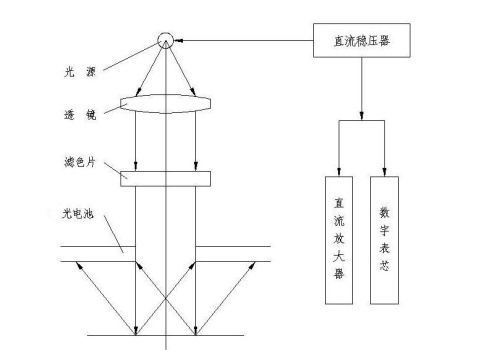

Operating Principle

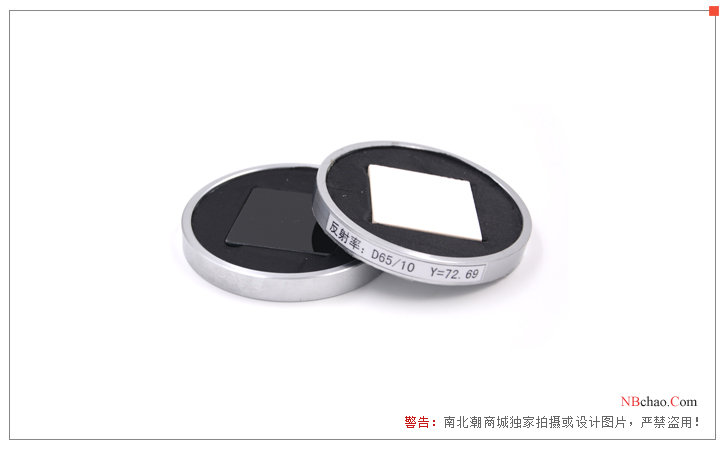

The C84-III reflectance Tester consists of a probe, a main unit, a standard plate (one black and white), and two working ceramic plates.

The probe adopts the principle of 0° irradiation and 45° reception. When the reflected light of the sample acts on the surface of the photocell, a telecommunication signal is generated and input to the DC amplifier for amplification, and the reading is displayed (see the optical path schematic diagram for details).

The C84-III reflectance meter indicates a value that is proportional to the intensity of the light reflected from the surface being measured.

Parameters

Indication range: 0~100

Display accuracy: 0.1

Power supply: 220v 50Hz

Live shot

How to use:

1) Connect the probe to the electric control box and turn on the power supply. Place the probe on a black standard plate and turn on the machine to warm up for 3 minutes. When connecting, it should be noted that the groove on the plug should be aligned with the protrusion on the socket of the electric control box, and the plug should be pinched when unplugged, and the metal sliding sleeve of the plug should be pulled back, and then the plug should be unplugged, and the wire should never be pulled directly.

2) Calibration: Put the probe on the black standard board, adjust the "zero" knob of the host, so that the number of the host is displayed as 00.0.

3) Calibration standard value: Put the probe on the white standard plate and adjust the "full" knob of the host to make the value displayed by the host consistent with the calibration value of the white standard plate. The allowable variation ± 0.1. Repeat the adjustment once (zero, full).

4) Measure the RB value: Move the probe to the black working ceramic plate where the specimen is placed, and the value displayed by the display is the RB value.

5) Measure the Rw value: Move the probe to the white working ceramic plate where the sample is placed, and the value displayed by the display is the Rw value.

6) Calculate and obtain the RB/Rw value of the coverage rate.

Precautions

1. In order to ensure the measurement accuracy, the measurement ambient temperature should be close to 25°C, and the C84-III reflectance Tester should be calibrated frequently.

2. In order to overcome the light fatigue of the photocell, the probe should be placed on the black standard plate during the test interval. Reduce the plug insertion and unplugging to avoid damaging the plug and causing poor contact.

3. The white standard plate should be kept away from pollution, otherwise it will affect the measurement reading.

4. If there is any stain on the white standard board, it can be removed with a high-grade drawing eraser.

5. The preparation of samples should be carried out in accordance with the relevant national standards.

Use, maintenance and troubleshooting

1) Use and maintenance:

The C84-III reflectance Tester adopts a highly sensitive photoelectric conversion device, which ensures that the illumination part and circuit part of the instrument are not affected by the external environment. Dust or moisture adsorbed on the translucent glass in the probe will affect the measurement reading, and should be wiped off with a lens cloth in time. The black and white standard board should be wiped clean before each use. If there are corrosive gases in the environment, the optoelectronic components in the instrument can be damaged.

It is better if the probe can be stored in a drying tank when not in use.

2) Troubleshooting:

phenomenonFailure analysisdisposeThe digital meter is on and the LED is not

| phenomenon | Failure analysis | dispose |

| The digital meter is on and the LED is not | 1. The probe lead is broken 2. The LED is damaged | Check the leads Replace the light-emitting diode |

| The numerical display of the numerical table is unstable | 1. The emission of LEDs is unstable 2. The Voltage regulator is unstable | Replace the light-emitting diode Check the regulated power supply |

The reflectance Tester is a special instrument, and when the fault cannot be eliminated, it should be handed over to the instrument maintenance personnel or contact the instrument manufacturer, and it should not be dismantled and repaired at will.

3) The C84-III reflectance Tester should be sent for inspection regularly to ensure the accuracy of use (1 time per year is recommended).

- 1ASTM 《Standard Test Method for Hiding Power of Paints by Reflectometry》

- 2JG/T 235-2014《Architectural reflective thermal insulation coating》

- 3JC/T 1040-2020《Exterior reflective thermal insulating coatings on buildings》

- 4GB/T 7048-2012《Colour carbon black - Determination of blackness》

- 5GB/T 34676-2017《Interior wall coatings for children's room decorating》

- 6GB/T 23997-2009《Solvent-thinned polyurethane wood coatings for indoor decorating and refurbishing》

- 7JJF 1232-2009《C.S. for Reflectometers》

- 8GB/T 9780-2013《Test method for dirt pickup resistance and stain remvoal of film of architectural coatings and paint》

- 9GB/T 9757-2001《Solvent-thinned coatings for exterior wall》

- 10ASTM D2805-2023《Standard Test Method for Hiding Power of Paints by Reflectometry》

C84-III

C84-III