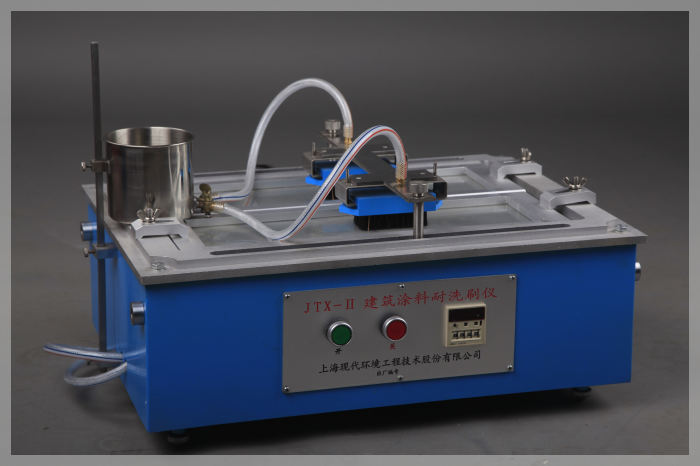

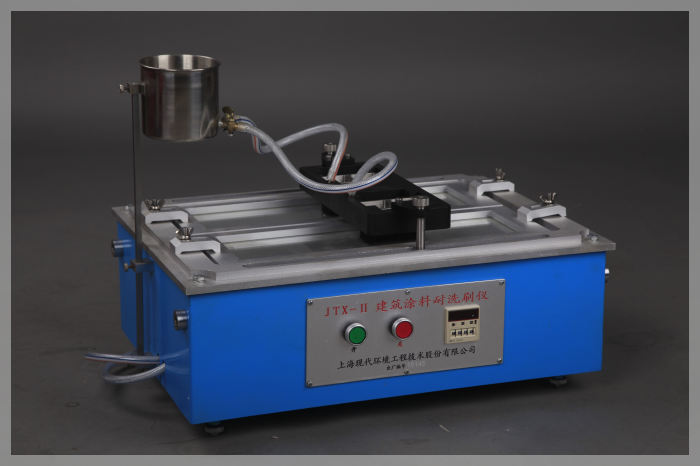

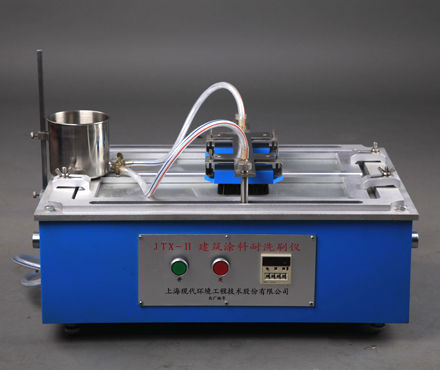

MODERNER JTX-II architectural coatings Scrub washability Testers 37 times/min Frequency reciprocating motion, standard stroke 300mm

Moderner JTX-II Architectural coatings Scrub washability TestersSPEC

Moderner JTX-II Architectural coatings Scrub washability TestersDetails

Moderner JTX-II Architectural coatings Scrub washability TestersPacking list

- SKU

- NB000662

- Brush Specifications

- 38*90mm

- Brush Weight (including brush)

- 450±2g

- Scruf stroke

- 300mm

- Scruf speed

- 37±1cpm

- Counter

- 4 digits

- Test board size

- 430*150*3mm

- Motor Power

- 90W

- Power Supply

- 380v 50Hz

- Dimensions

- 600*430*450mm

- Machine Weight

- Approx. 50kg

Introduction

The brush (including brushes) weighs 450g and reciprocates at a frequency of 37 times/min, with a standard stroke of 300mm.

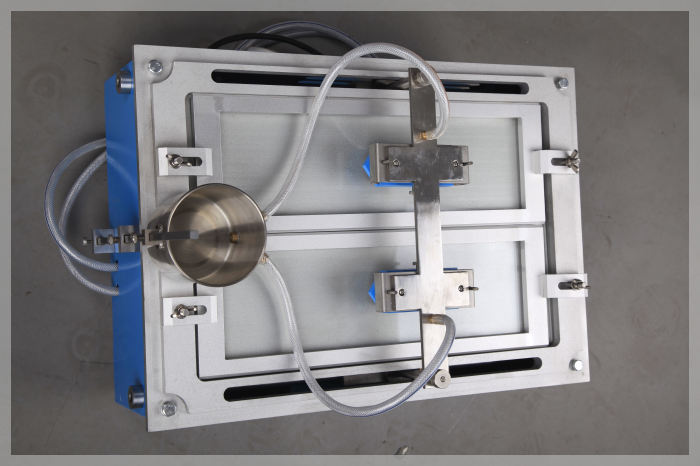

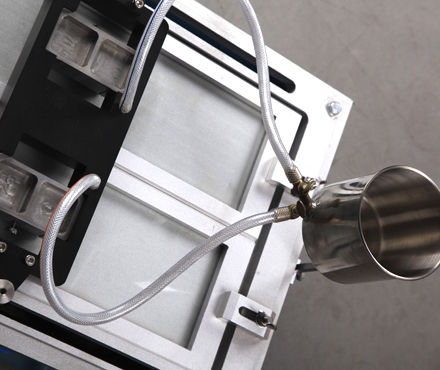

The reservoir on the upper part of the JTX-II Architectural Paint Scrubbing Resistant Scrubbing Instrument for Modern Environments is used to store the soapy water used in the test. During the test, the water output speed should be adjusted according to the requirements of the national standard.

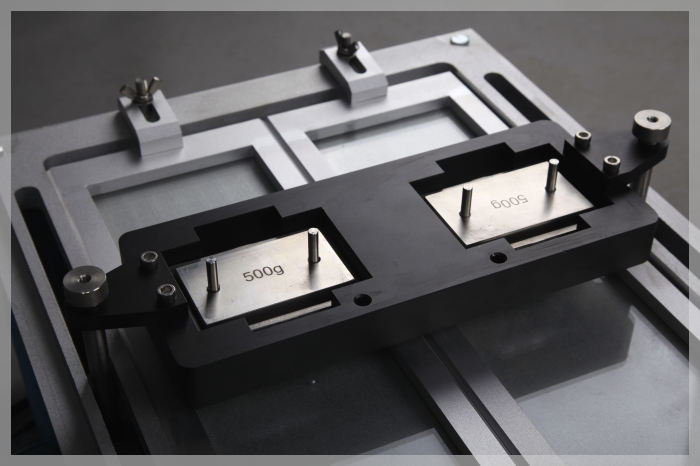

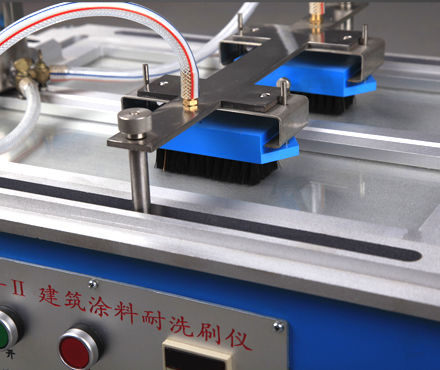

According to the thickness of the test plate, a qualified washer is selected to ensure that the brush clamp with pins is assembled in the brush clamp hole on the beam, and can move up and down freely, so that the weight of the brush 450g is always pressed on the test board.

Parameters

| Model | JTX-II |

| Brush Specification (mm) | 38x90 |

| Brush weight (including brushes) (g) | 450±2 |

| Brush reciprocating stroke(mm) | 300 |

| Brush running frequency (times/min) | 37±1 |

| Counter (bits) | 4 |

| Test board size (mm) | 430x150x3 |

| Motor power(W) | 90 |

| power supply | 380v 50Hz |

| Dimensions | 600x430x450 |

| Weight (kg) | Approx. 50kg |

Actual picture of the product

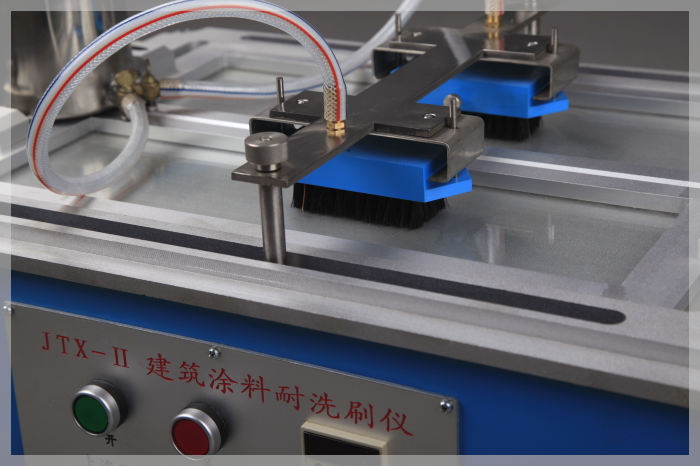

Use the operating instructions

1) Soak the brush in water at 20°C for 30 minutes at a depth of 12mm, then take out the brush and press it dry, and soak it in 0.5% soap for 10 minutes.

2) Put the test plate in the working plate, and then clamp the test plate with quick fixtures on both sides (the height of the rubber chuck can be adjusted according to the thickness of the test plate), and the test plate shall not have a series of movement in the work.

3) Load the brush into the brush base, tighten the fixing bolt to fix the brush from loosening, and then connect it with the beam brush holder, and control the gap between the brush and the beam frame at 3~5mm to ensure that the brush moves freely.

4) Put the washing medium (dissolve the washing powder in distilled water and prepare it into a 0.5% solution, its PH value is 9.5~10.0, and the washing medium can also be other media specified in the product standard) into the water storage cylinder.

5) Turn on the power, the counter shows "0", press the preset key to reach the required number of times, then press the start switch, the brush starts to move, the counter counts by itself, and the washing medium should be continuously injected during the washing process to keep the test plate wet. The dropping acceleration should be in line with the national standard GB9266 and 0.04g per second.

6) Observe whether there is wear and exposure at the middle 10 cm of the test board, and if you want to stop halfway (not to the preset value), press the stop switch (try to stop the brush at both ends), stop washing, and just press the start switch if you want to continue washing.

7) When the test piece is not exposed, the counter has reached the predetermined value and stops, if you want to continue the test, you need to press the counter reset switch (RESET) first, and the counter will show back to zero, otherwise it will not start, and then press the start switch, and the counter will start counting again, and the number of washing and brushing will be accumulated.

8) If it is used to inspect the product, you only need to dial the preset value to the qualified value, start the machine, and automatically stop when the predetermined value is reached, and check whether the test board is exposed, so as to judge whether the product is qualified.

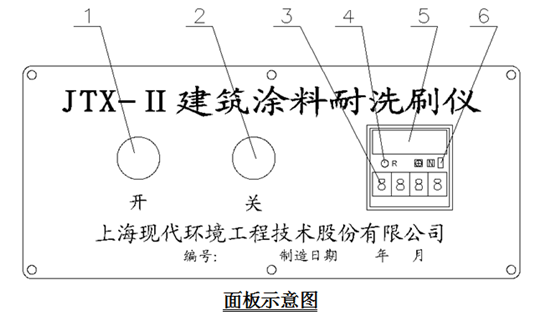

9) See the panel diagram for panel operation.

1 - start button; 2 - stop button; 3 - set number; 4 - reset button RESET; 5 - counter display window;

6 - Counting status selection switch: ⊕ — Additive counting with power failure memory;+ — Additive counting without power failure memory;

- — Subtractive counting without power failure memory;N — When the count reaches the preset number, the relay contact is transpositioned and the counting cannot be continued

Precautions

1. The motor needs to run clockwise (the brush stops at the side position when it stops), and the motor needs to run counterclockwise (the brush stops near the middle position when it stops), which will cause noise and shaking. In the case of counterclockwise operation, it is necessary to change the phase of the power supply inlet.

2、JTX-II Architectural Coatings Scrubbing Resistance TesterDuring normal operation, it is strictly forbidden to press the counter reset switch casually, otherwise it will cause inaccurate counting.

3. Press the reset switch before each start, and the counter is displayed as "0"

4. After each test, the reservoir, glass plate, brush and instrument workpiece should be cleaned, and the panel and instrument body should be wiped dry with a dry cloth to prevent corrosion.

5、JTX-II Architectural Coatings Scrubbing Resistance TesterAfter half a year of use, the oil level of the reducer should be checked, and the oil dipstick should be taken out first to see whether the oil level is on the standard line of the oil dipstick, and if it is lower than the standard line, it is necessary to add No. 20 gear oil. The oil level shall not be higher than the standard line, too high will affect the normal operation of the reducer.

6. The production of the test plate should meet the requirements of national standards.

7、Modern Environment JTX-II Architectural Coatings Scrubbing Resistant InstrumentPlaced on the tabletop, you need to keep it level, adjust the foot screws, and then test.

- 1JJF 001-2015《Calibration Specification for Paint Film Scrub Resistance Testers》

- 2GB/T 34676-2017《Interior wall coatings for children's room decorating》

- 3ASTM D3450-15《Standard Test Method for Washability Properties of Interior Architectural Coatings》

- 4GB/T 9266-1988《Determination of scrubbing resistance of architectural coatings coatings (neq JISK 1663:1981)》

- 5GB/T 9266-2009《Determination of washing resistance of architectural coatings coatings》

JTX-II

JTX-II