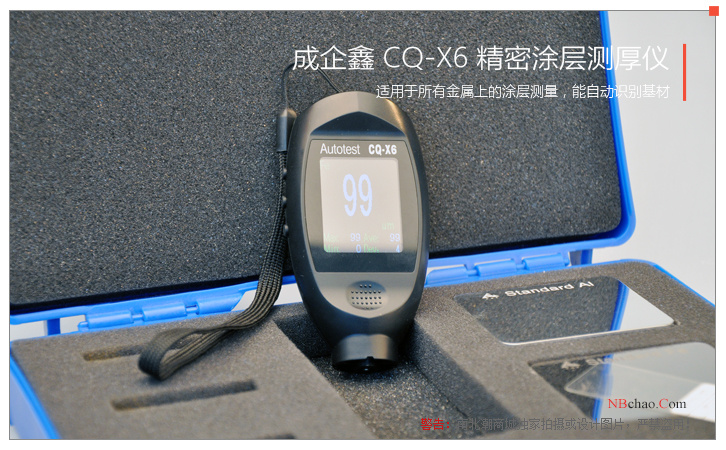

CQX CQ-X6 Precision coating Thickness Gauge for automatic substrate identification of coatings on all metals

SE-

IPRE CT400 magnetic Induction eddy Current Coating Thickness Gauge Measurement range 0~1500μm$ 254.00SE

IPRE CT400 magnetic Induction eddy Current Coating Thickness Gauge Measurement range 0~1500μm$ 254.00SE -

AMITTARI AC-110A built-in thickness probe with resolution of 0.1 μm$ 341.00SE

AMITTARI AC-110A built-in thickness probe with resolution of 0.1 μm$ 341.00SE -

Statistical Coating Thickness Gauge AMITTARI AC-110B Integrated Sensors can store 99 sets of thickness measurement data$ 506.00SE

Statistical Coating Thickness Gauge AMITTARI AC-110B Integrated Sensors can store 99 sets of thickness measurement data$ 506.00SE -

LANDTEK CM8825Fn platings Thickness Measurement Instrument Dual function coating Thickness Measurement Instrument$ 386.00SE

LANDTEK CM8825Fn platings Thickness Measurement Instrument Dual function coating Thickness Measurement Instrument$ 386.00SE -

LANDTEK CM8828 Film Thickness Gauge for automotive coatings$ 386.00SE

LANDTEK CM8828 Film Thickness Gauge for automotive coatings$ 386.00SE

CQX CQ-X6 Precision coating Thickness GaugeSPEC

CQX CQ-X6 Precision coating Thickness GaugeDetails

CQX CQ-X6 Precision coating Thickness GaugePacking list

- SKU

- NB000694

- Measurement principle

- Magnetic Induction + eddy Current

- Measurement range

- 0~1250μm

- margin of error

- ±3%

- probe

- F and NF integrated probes

- statistical function

- MAX Maximum, MIN Minimum, Average, Standard deviation

- icon function

- without

- Power

- 2 * AAA 1.5V battery

- Calibrated Certificate

- without

- Language

- Chinese

- Display screen

- 1.8 inch TFT LCD

- supporting software

- without

- Machine Weight

- 41g

- Machine size

- 96*50*25mm

- Storage temperature

- -10~60℃

- Operating temperature

- 0~40℃

Product Description

The CQ-X6 precision coating Thickness Gauge is a small-sized handheld precision coating Thickness Gauge produced by Chengqixin. It has a built-in F/N probe and can automatically identify different substrates for thickness measurement.The shell of the CQ-X6 precision coating Thickness Gauge is a black hard plastic shell with good wear resistance and a large LCD. The measured thickness range is 0~1250 microns. It is powered by a battery and is suitable for off-site thickness measurement work.

Chengqixin CQ-X6 precision coating Thickness Gauge is a composite Thickness Gauge suitable for coating measurements on all metals. The precision Thickness Gauge depends on the base material when measuring. Each time the reading is displayed, the letters Fe (magnetic conductive metals, such as iron and steel) or NFe (non-magnetic conductive metals, such as aluminum and alloys) are also displayed. The precision Thickness Gauge has a 1.8-inch TFT screen that can simultaneously display the maximum value, minimum value, average value and error value of the measurement process.

Actual pictures

How to operate

1. Press down the probe to automatically turn on the power and start measurement. After 30 seconds of inactivity, the power will automatically turn off.

2. Place the probe of the CQ-X6 precision coating Thickness Gauge squarely on the surface of the coated substrate to be measured. Hold the Thickness Gauge steadily. When the measurement is completed, the precision Thickness Gauge will beep.

3. Pick up the Thickness Gauge and display the reading. (Note: The symbol "------" is displayed when the range is exceeded)

CQ-X6 precision coating Thickness Gauge function operation

1.UVLED: Tap the "+" button once to turn on the UVLED, and tap the "+" button once again to turn off the UVLED.

2.LED: Press the "-" button once to turn on the LED, and press the "-" button once again to turn off the LED.

3. Color change: Press the "+" button for 2 seconds to change the display and font color.

4. Flip the display: Press the "-" button for 2 seconds to flip the display 180 degrees.

5. Unit switching: Press the "M" button 3 times continuously, the buzzer will sound, and the conversion between "um" and "mil" is completed.

6. Calibration:

a) Uncoated calibration: Press the "M" button 2 times continuously, the screen will display "00" and the buzzer will sound "beep, beep, beep...". At this time, place the Thickness Gauge probe flat on the On the surface of the uncoated substrate to be measured, hold it firmly. The Thickness Gauge will beep and the screen will display "0". Pick up the Thickness Gauge and complete the uncoated zero reset.

b) Standard piece calibration: After measuring the standard piece, lightly press the "M" button once, the buzzer will beep, beep, and the current measurement data will flash twice. Then, press the "+" or "-" button to change the reading. Adjust it to be consistent with the standard film. Finally, lightly press the "M" button once and the buzzer will "beep" once to confirm the modified data.

c) Restore factory parameters: Press the "+" or "-" button at the same time, release the button when the buzzer prompts "beep, beep, beep." to complete the factory restore operation.

7. Clear the maximum, minimum, average and error values: Press the "M" button 4 times continuously, the buzzer will sound "beep", and the measured maximum, minimum, average and error values ââcan be cleared.

8.Battery low Voltage alarm:

When "There is an X mark in the battery" appears on the screen, the measured value may be inaccurate. Please replace the battery.

- 1Introduction of nondestructive thickness testing principle and instrument

- 2Correct use of Film Thickness Gauge

张瑞;张月富

- 3Application Value of Coating Thickness Gauge in Steel Structure Coating Construction

- 4What is the significance of coating Thickness Gauge calibration? How to calibrate? When to calibrate?

- 5How to choose a Thickness Gauge?

- 6National testing standards commonly used in car painting

- 7Film Film thickness determination

- 8How to measure the thickness of galvanized coating

- 9Measuring methods of coating Thickness Gauge

- 10Choice of Coatings

- 1QJ 990.3A-2011《Inspection methods of coating.Part 3:Measurement of coating thickness》

- 2NF EN ISO 2808-2007《Paints and varnishes - Determination of film thickness.》

- 3JJG 818-2018《Magnetic and Eddy Current M easuring I nstrument for Coating Thickness》

- 4GB/T 1727-2021《General methods for preparation of coating films》

- 5HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 6HG/T 5367.1-2018《Coatings for rail transit vehicles - Part 1: Waterborne coatings》

- 7ASTM B244-2021《Standard Test Method for Measurement of Thickness of Anodic Coatings on Aluminum and of Other Nonconductive Coatings on Nonmagnetic Basis Metals with Eddy-Current Instruments》

- 8ASTM B499-2021《Standard Test Method for Measurement of Coating Thicknesses by the Magnetic Method: Nonmagnetic Coatings on Magnetic Basis Metals》

- 9 B530-2014《》

- 10ISO 2360-2017《Non-conductive coatings on non-magnetic electrically conductive base metals — Measurement of coating thickness — Amplitude-sensitive eddy-current method》

CQ-X6

CQ-X6