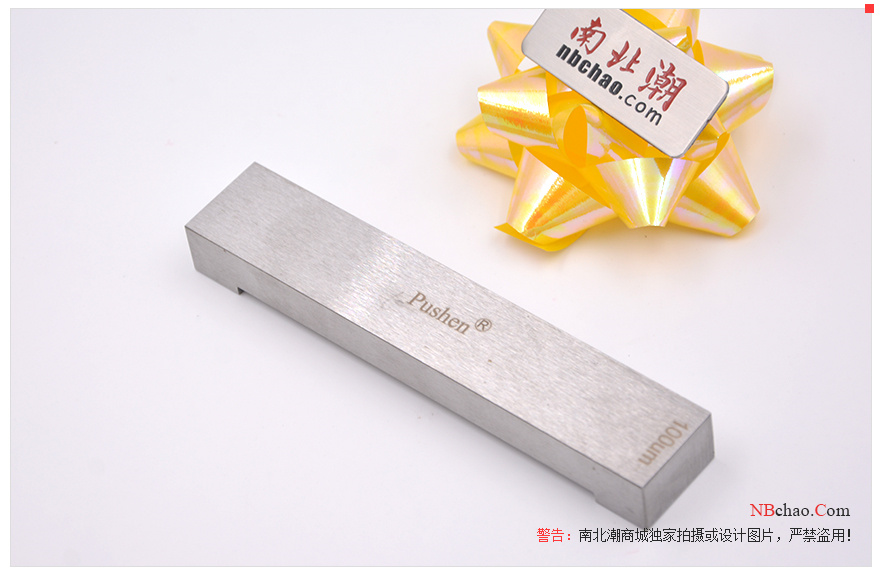

PUSHEN /Pushen SZQ-600 Single Sided Film Applicator Moulding 600um

SEPushen SZQ-600um Single Side Film ApplicatorSPEC

Pushen SZQ-600um Single Side Film ApplicatorDetails

Pushen SZQ-600um Single Side Film ApplicatorPacking list

- SKU

- NB000695

- type

- one-sided

- WFT

- 600µm

- Application width

- 100mm

- material

- stainless steel

- size

- 128mm

Introduction of paint applicator knowledge

It is well known that the reliability of coating laboratory testing is directly related to the quality of the samples provided, especially in paints, varnishes, paints, inks, glues and cosmetics. Whether you want to explain the appearance characteristics of the product or such as color, gloss, dryness and hiding power, etc., and no matter what kind of coating you test on, the most basic condition is that the sample needs to be uniform, comparable and accurate in thickness control .

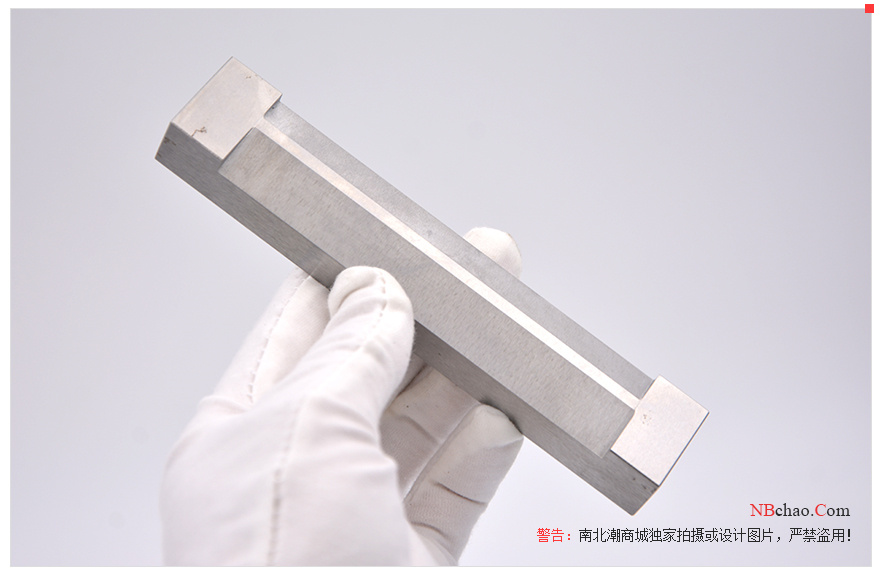

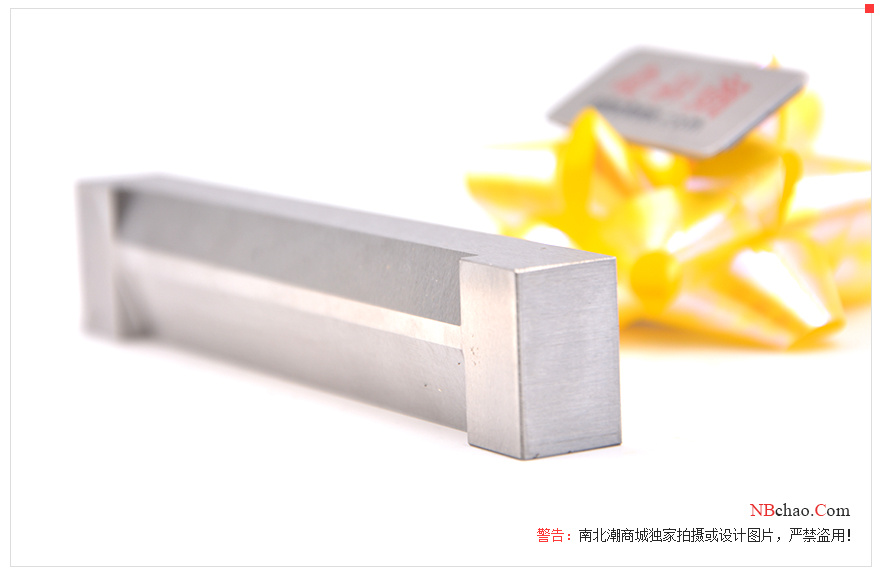

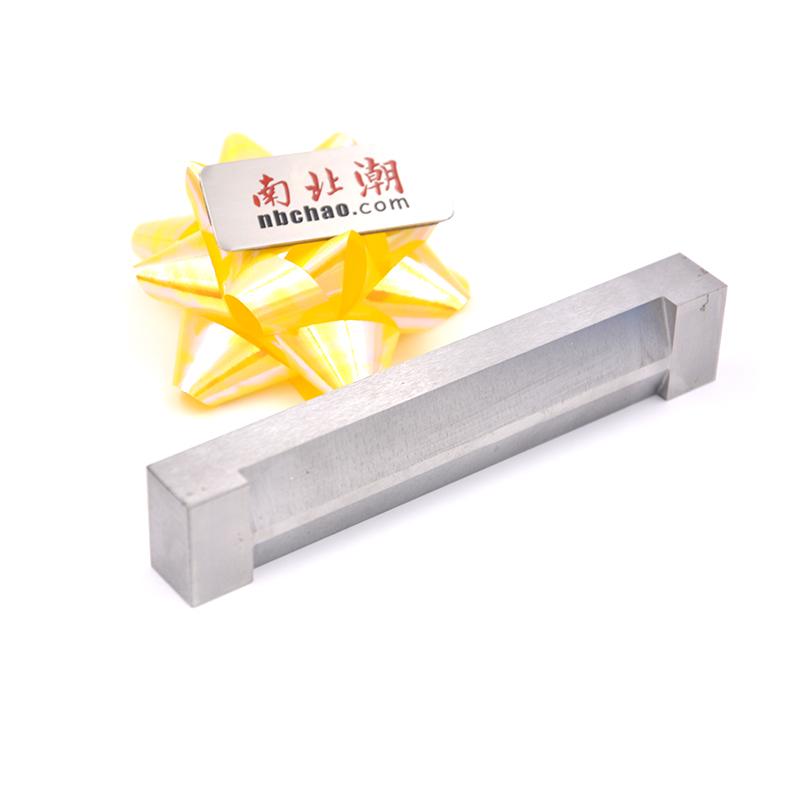

Pushen's SZQ-600 single-sided Wet Film Applicator is made of hard stainless steel and is suitable for scraping a film of specified thickness and width on a flat and solid substrate. Each Wet Film Applicator has 1 to 4 high-precision fixed film thicknesses. While providing high-precision film thickness, there are also various film widths for customers to choose.

Introduction of Coating Wet Film Applicator

●The material is high-grade stainless steel, which ensures that the applicator is not corroded by acidic or alkaline substances in paint or cleaning agent.

●Mainly used to coat a certain thickness of wet film to measure the color and hiding power of the sample or to prepare a sample, etc.

Introduction of paint leveling

The so-called leveling property of the coating refers to the smooth and smooth state of the coating film after the coating is applied.

If the surface has good leveling properties, there will be no irregularities such as orange peel, brush marks, ripples, and shrinkage cavities. Usually people directly observe with the naked eye to compare the sample with the standard sample in parallel to judge the quality of the leveling property of the coating film. This method varies from person to person and is highly subjective.

Paint Wet Film Applicator is widely used in products such as ink, paint, varnish, coating, glue and cosmetics

Function introduction of coating Wet Film Applicator:

Single-sided or four-sided wet film preppers are constructed of hardened stainless steel to apply film layers of specified thickness and width to flat, solid substrates.

Each Film Applicator has 1 or 4 high-precision fixed film thicknesses to ensure accuracy, and a variety of film widths can be customized.

Coating Wet Film Applicator model selection:

Ordering Information | SZQ single-sided Wet Film Applicator | |

film thickness | Coating film width (mm) | Total length (mm) |

25um | 100 | 128 |

37.5um | 100 | 128 |

50um | 100 | 128 |

75um | 100 | 128 |

100um | 100 | 128 |

125um | 100 | 128 |

150um | 100 | 128 |

200um | 100 | 128 |

250um | 100 | 128 |

300um | 100 | 128 |

400um | 100 | 128 |

500um | 100 | 128 |

600um | 100 | 128 |

700um | 100 | 128 |

800um | 100 | 128 |

900um | 100 | 128 |

1000um | 100 | 128 |

2000um | 100 | 128 |

- 1YS/T 680-2016《Powder for coating aluminium alloy extruded profiles for architecture》

- 2GB/T 1727-2021《General methods for preparation of coating films》

- 3HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 4HG/T 3951-2007《Water based colorants for architectural coatings》

- 5GB/T 9755-2014《Synthetic resin emulsion coatings for exterior wall》

- 6GB 1727-1992《Paint film general preparatory method》

SZQ-600um

SZQ-600um