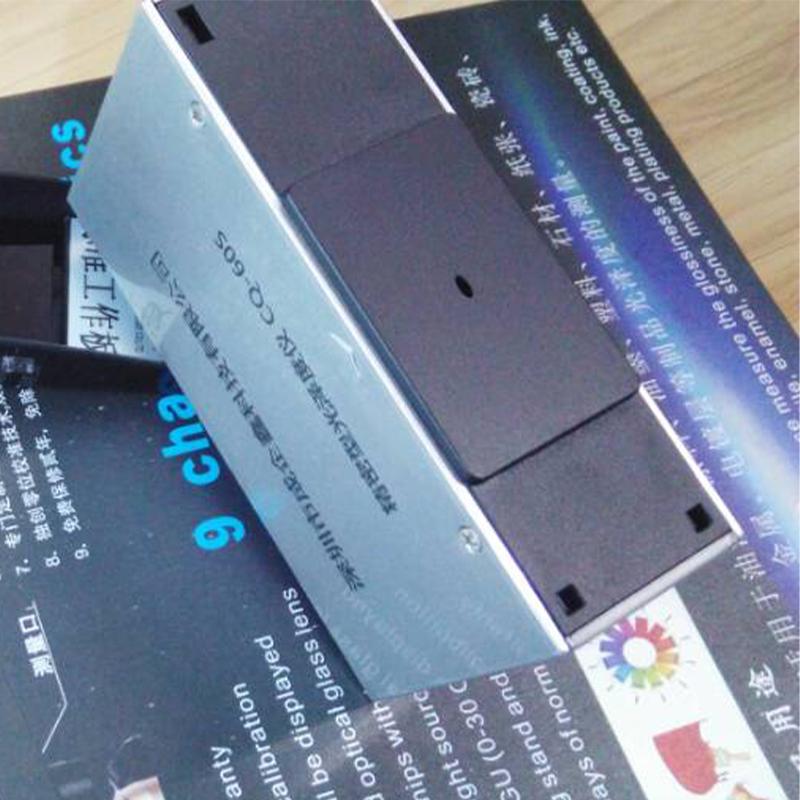

CQX CQ-60S Small hole Glossmeter 60 °

SE-

Curved small hole Glossmeter JFL-B60S (curved small hole 1.5 * 3mm ordinary type)$ 444.00SE

Curved small hole Glossmeter JFL-B60S (curved small hole 1.5 * 3mm ordinary type)$ 444.00SE -

KSJ MG6-SA Microporous Gloss Meter, range 0~999GU polished mirror measurement

KSJ MG6-SA Microporous Gloss Meter, range 0~999GU polished mirror measurement -

QILI MN60-CH Small hole curved Glossmeter$ 627.00SE

QILI MN60-CH Small hole curved Glossmeter$ 627.00SE -

IWAVE WG60G small hole Glossmeter 60 ° small hole Glossometer repeability accuracy is 0.2$ 541.00SE

IWAVE WG60G small hole Glossmeter 60 ° small hole Glossometer repeability accuracy is 0.2$ 541.00SE -

Netherlands TQC GL0010 Gloss Meter 60 ° Single Angle Glossiness Meter$ 3616.00SE

Netherlands TQC GL0010 Gloss Meter 60 ° Single Angle Glossiness Meter$ 3616.00SE

CQX CQ-60S Small hole GlossMeterSPEC

CQX CQ-60S Small hole GlossMeterDetails

CQX CQ-60S Small hole GlossMeterPacking list

- SKU

- NB000696

- Measurement angle

- 60°

- Measurement range

- 0~199.9GU

- Error of indication

- <1.2GU

- Graduation

- 0.1GU

- Standards

- JJG first-class glossmeter standard, ISO-2813

- Operating language

- Chinese

- Dimensions

- 114*35*65mm

- Measurement port size

- 3*1.5mm

- Stability

- ±0.4GU

- Operating Voltage

- 3V

- Measurement port shape

- ellipse

Introduction

The CQ-60S small hole type gloss meter has an oval measuring window of 1.5x3mm and a small measuring aperture. It is a high-precision, compact and portable gloss meter. The small hole gloss meter is not only suitable for flat surface gloss measurement, but also widely used for gloss value measurement on coating surfaces with curved surfaces or special irregular shapes. The gloss meter is manufactured in compliance with ISO-2813 standards. It is suitable for measuring the surface glossiness of complex-shaped surfaces such as mechanical parts, jewelry, handicrafts, plastic pipes, hardware decoration, test samples, etc.

Instructions

Press the switch, place the small hole gloss meter on the black glass standard plate, and rotate the adjustment button to make the displayed value the same as the nominal value of the standard plate.

Measurement skills

1. When moving from a place with a lower temperature to a place with a higher temperature (such as outdoor to indoor in winter), please wait for a while before taking the measurement. (Because the optical lens changes from a place with low temperature to a place with high temperature

The surface of the lens will become foggy)

2. Please do not measure in an environment where the object under test is exposed to direct sunlight to avoid affecting the measurement value.

3. When using a small hole gloss meter to measure a curved surface object, in order to ensure that the small hole is completely covered, the measuring hole of the gloss meter can be slowly covered with the measured object along the tangent line of the measured curved surface.

Until the light spot on the measured object is no longer visible (the white light spot illuminated by the measuring hole on the measured object).

Precautions

1. Body:

1) The gloss meter is an optical precision instrument and should avoid severe impact.

2) Try to place it in a dry and clean environment.

3) When the gloss meter is not suitable, please place the detection window downward to avoid contamination in the measurement chamber.

4) After the measurement, be sure to turn off the power, put the small hole gloss meter into the instrument box and put it in a clean place for the next measurement.

2. Accessories:

1) Keep the standard plate of the small hole gloss meter clean to avoid measurement errors caused by inaccurate readings during instrument calibration.

2) When the standard plate is stained, please wipe it with lens tissue or lens cleaning cloth. The black standard plate can be wiped with lens paper dipped in absolute ethanol.

3. Calibration:

1) When calibrating the small hole gloss meter, the single angle is placed in the inner frame of the standard plate box.

- 1Film Gloss

- 2Glossmeter Classification and Measurement principle

- 3Introduction to coating performance testing

- 4Determination of Film Gloss (glossiness)

- 5Rhopoint Gloss Meter Testing in Special Scenarios FAQ

- 6How to improve the measurement accuracy of gloss meter?

- 7What is the difference between the gloss meter GU and GS units?

- 8Chengqixin glossiness instrument related selection guidance

- 9Mirror glossiness - ASTM D523

- 10Introduction of coating surface roughness inspection method

- 1GB/T 13217.2-2024《Test method for gloss of ink》

- 2GB/T 11420-1989《Measurement of specular gloss of vitreous and porcelain enamels》

- 3GB/T 13448-2019《Test methods for prepainted steel sheet and strip》

- 4HG/T 2006-2006《Thermosetting powder coatings》

- 5GB/T 33876-2017《Method for measuring gloss uniformity of image on colour copied pages》

- 6GB/T 23997-2009《Solvent-thinned polyurethane wood coatings for indoor decorating and refurbishing》

- 7HG/T 5183-2017《Water-based ultraviolet curing coatings for woodenware》

- 8HG/T 5180-2017《Water-based Coatings for Automotive Plastic Parts》

- 9ASTM D3794-2022《Standard Guide for Testing Coil Coatings》

- 10JJG 696-2015《Specular Gloss Meters and Gloss Plates》

CQ-60S

CQ-60S