MODERNER WJ-2.2C Variable Speed Stirrer (Brushless DC Type) is suitable for dispersing, blending and stirring various liquid materials

Moderner WJ-2.2C Variable Speed StirrerSPEC

Moderner WJ-2.2C Variable Speed StirrerDetails

Moderner WJ-2.2C Variable Speed StirrerPacking list

- SKU

- NB000717

- Power

- 220V 50Hz/60Hz

- Power

- 2200W

- Speed range

- 300~4000rpm

- Impeller configuration

- Φ120mm

- Lifting stroke

- 350mm

- Dimensions

- 500*580*1140mm

- Machine Weight

- 100kg

product description

WJ-2.2C variable speed mixer (brushless DC type) is suitable for dispersing, blending and mixing various liquid materials in laboratories and pilot production. This machine is driven by a brushless DC motor, has stepless speed regulation, and has functions such as stirring speed display. Due to the use of a brushless DC motor, this machine has larger and more stable driving torque than AC motors of the same specification, and avoids the trouble of replacing brushes with traditional DC motors.

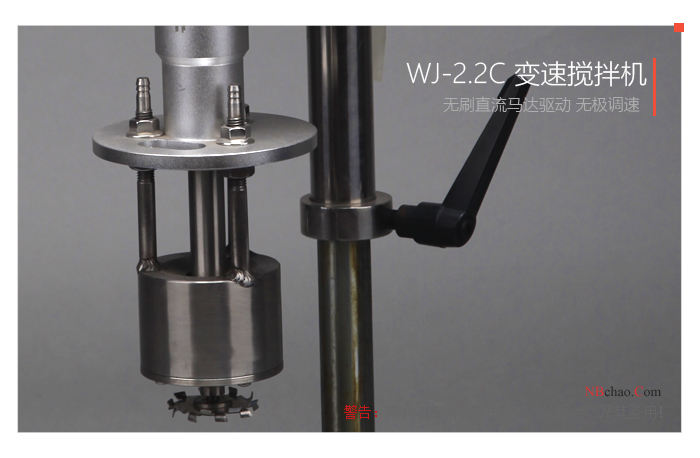

Actual pictures

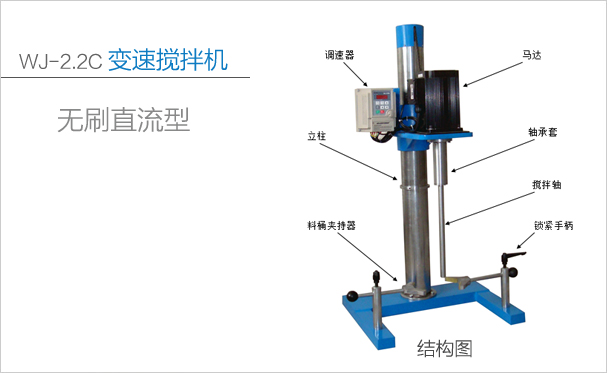

Product Structure

Product structure brief description

1. The electrical control of this machine adopts a small brushless DC motor controller, which is directly installed on the motor bracket.

2. The lifting device consists of a column, a motor bracket, a counterweight, etc. Loosen the locking handle on the motor bracket, and the motor bracket can move up and down.

3. The stirring device consists of a stirring shaft, a bearing sleeve, a dispersing blade, etc., and is directly connected to the motor.

4. The barrel clamping device consists of a barrel holder, a locking handle, etc.

Use and maintenance

1) First remove the fixing screws (right side of the column) used for transporting the host.

2) Connect the power supply to the motor controller.

3) When working, first press the "Return" button, then slowly turn the speed adjustment knob to the required speed

4) When shutting down, you should first use the speed control knob to reduce the speed, and then press "STOP" to shut down the machine to avoid the material liquid from splattering due to too fast speed increase next time the machine is turned on.

5) Fix the barrel with a clamping device. The material in the bucket should not be filled too full to avoid splashing during mixing. The barrel is prepared by the user or ordered separately.

6) Lock the locking handle on the motor bracket before starting the machine.

7) When not in use for a long time, anti-rust oil should be applied to the column.

8) This machine is used in the production process of chemical raw materials. Users should establish appropriate safety and protective measures and determine rules and regulations in accordance with relevant safety regulations before use. Safety issues related to contact with chemical raw materials should be established by the user and are beyond the scope of this manual.

WJ-2.2C

WJ-2.2C