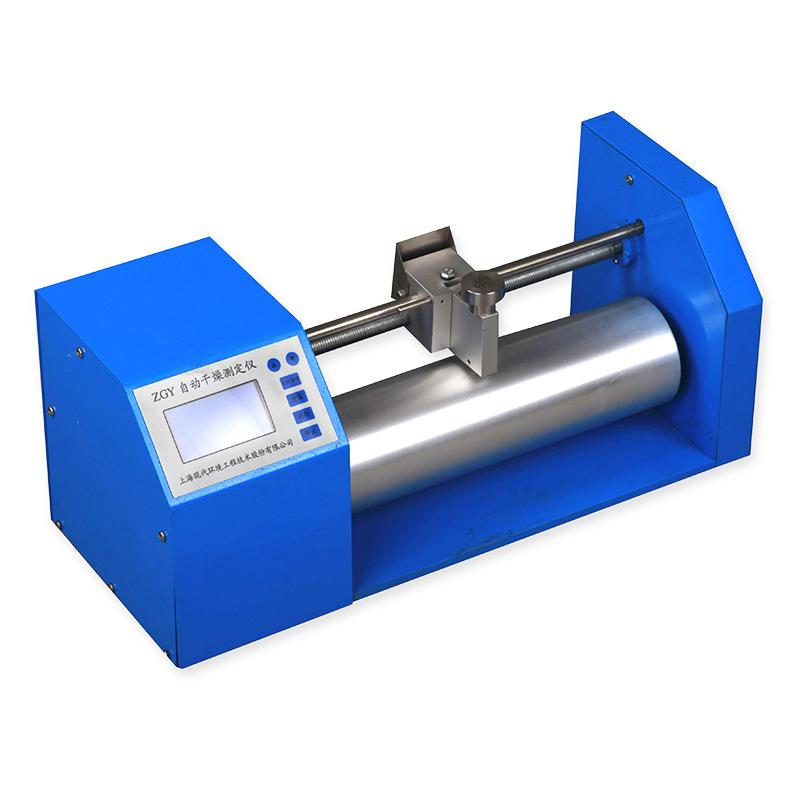

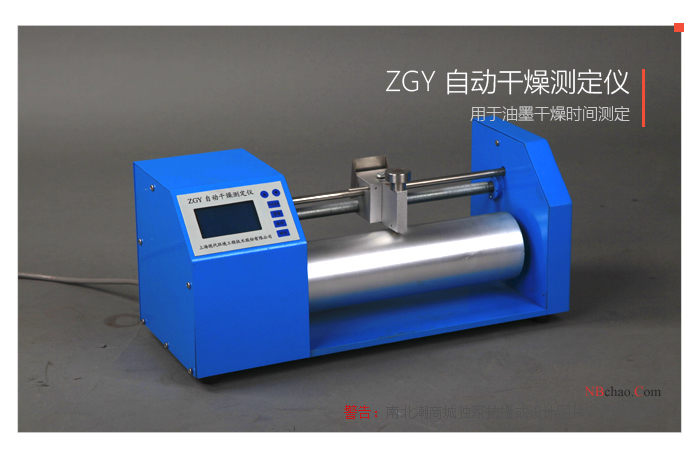

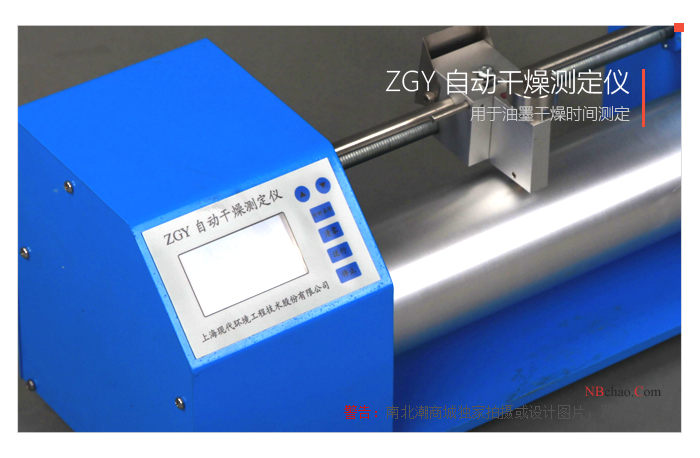

MODERNER ZGY automatic drying Tester for determining inks drying time QB562-83 standard

SEModerner ZGY Automatic drying TesterSPEC

Moderner ZGY Automatic drying TesterDetails

Moderner ZGY Automatic drying TesterPacking list

- SKU

- NB000721

- Power Supply

- 220v 50Hz

- Pressure wheel Mass

- 100g

- Pressurized wheel traverse speed

- 2mm/r

- Test Timer (16 gears)

- 5~20h

- The number of rings of the round drum in the whole process

- 120r

- Per revolution time Accuracy

- ±0.025s

- Overall Dimensions

- 500*200*220mm

- Instrument Weight

- 17kg

Introduction

ZGY Automatic Drying Tester (Ink Drying Tester) is mainly used to measure the drying time of ink. It is designed and manufactured in strict accordance with the requirements of the Ministry of Light Industry Standard QB562-83 "Ink Dryness Test Method". The definition of ink drying time in the standard: "Under certain pressure conditions on the ink scraping sample added with quantitative dry oil, the time required to prevent the sulfuric acid paper on the scraping sample from sticking to the color is the drying time of the ink, expressed in hours. , the test is carried out under the conditions of comparison between the standard sample and the sample."

ZGY type automatic drying Tester adopts single-chip microcomputer control technology, and the relevant test parameters are displayed on the LCD. For comparison, the standard scraping sample, the test scraping sample and the covered sulfuric acid paper are fixed on the cylinder of the automatic drying Tester with an adhesive tape. The constant ratio moves slowly along the axis of the circular drum. The drying time of the ink can be converted by counting the number of sticky bars on the sulfuric acid paper.

Safety Precautions

ZGY Automatic Drying Tester is used in the testing process of chemical raw materials, users should establish appropriate safety and sanitation protection measures and determine rules and regulations according to relevant safety regulations before use. Safety issues related to contact with chemical raw materials should be established by the user and are not within the scope of this manual.

Product photo

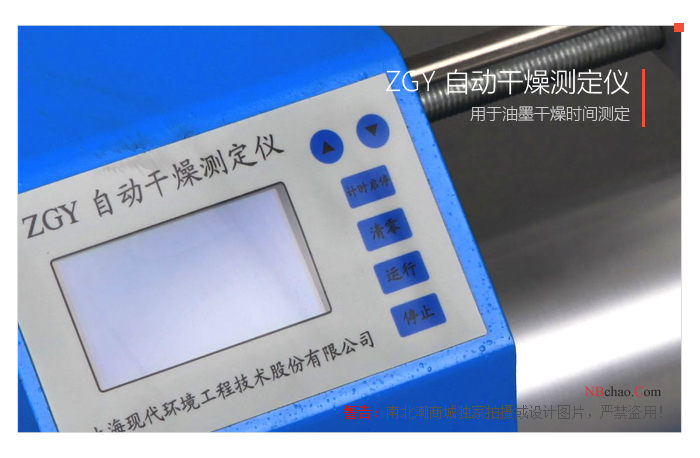

Key Description

| press key | illustrate | Remark |

"↑", "↓" keys | Increase and decrease the test timing by 1 hour, and cycle switching between 5 and 20 hours. | Valid when timing is cleared |

| "Timing reset" key | Clears the displayed data for compensation timing, laps and test timing. | Effective when the round drum stops |

| "Timer start and stop" button | Start, pause compensation timing. | The test timing is not cleared after reaching the set value, or it is invalid after the pressure wheel touches the limit switch |

| "Run" key | Start the rotation of the round drum, and automatically stop the compensation timing at the same time. | |

| "Stop" key | Stop the rotation of the round drum, and automatically start the compensation timing at the same time. |

Summary of Experimental Test Operations

1) The test temperature is 25°C±1°C, and the Relative Humidity is 60% to 70%.

2) Turn on the power switch on the back of the drying Tester, and the buzzer will make a beep.

3) The LCD displays the start-up interface in turn, and finally stays on the main interface. The main interface is as follows

test timing20 hours

Compensation timing00:00:00

Number of revolutions000.0

test timing00:00:00

4) Adjust the "Test Timing" (20 hours by default) according to the estimated ink drying time. The comparison table between the test timing and the time per revolution of the circular cylinder (that is, the interval between adjacent color sticking strips on the sulfuric acid paper) is as follows:

| Test timing (hours) | 05 | 06 | 07 | 08 | 09 | 10 | 11 | 12 |

| Time per revolution (minutes) | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 |

| Test timing (hours) | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 |

| Time per revolution (minutes) | 6.5 | 7 | 7.5 | 8 | 8.5 | 9 | 9.5 | 10 |

5) Weigh the sample and standard white dry oil on the analytical balance according to the following proportions, mix thoroughly, and weigh the standard sample and standard white dry oil in the same way and mix thoroughly. Ink to dry oil ratio:

Resin ink: sample (or standard sample) ink: standard white dry oil = 95:5

Oil type ink: sample (or standard sample) ink: standard white dry oil = 90:10

6) Scrape the well-mixed ink standard sample and the sample side by side to form a scraping sample about 30 cm long; press the "timing start and stop" button to start the test timing and compensation timing; then wrap the scraping sample covered with sulfuric acid paper in the automatic drying Tester On the round drum, fix it with adhesive tape.

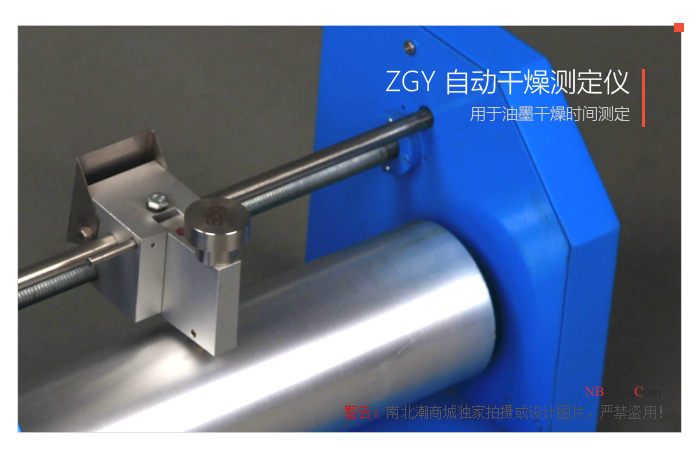

7) Move the pressure wheel to the right of the screw, and press it on the scraping sample covered with sulfuric acid paper; press the "run" button to start the rotation of the circular cylinder (the compensation timing will automatically stop), and the pressure wheel will start scratching.

8) During operation, you can press the "Stop" button to stop the rotation of the drum (the compensation timing will automatically restart), so as to observe the scratches; then press the "Run" button to resume the rotation of the drum (the compensation timing will automatically stop).

9) When the "test timing" reaches the "test timing" value, or the pressure wheel touches the limit switch on the left, the automatic drying Tester will automatically stop running, beep three times and freeze the display on the display. It is also possible to press the "stop" button first after observing that the ink marks are no longer drawn by the pressurizing wheel, and then immediately press the "timing start and stop" button to stop the round cylinder from running, and freeze the "compensation timing" display.

10) Take off the sulfuric acid paper to check the ink mark interval, multiply by the time per revolution and add the compensation timing, which is the ink drying time. Find the difference between the drying time of the sample and the standard sample, and check whether it is suitable.

11) It is necessary to press the "timing reset" key to clear the display before the next test can be performed.

Precautions for use and maintenance

1. The automatic drying Tester should be placed on a stable and flat laboratory operating table away from strong magnetic fields, strong electric fields, and strong electromagnetic pulse interference.

2. After the test is completed, it is necessary to readjust the "test timing", or before starting a new test, it is necessary to use the "timing reset" key to clear the display data of the previous test, otherwise the relevant keys are invalid.

3. For faster-drying inks, a shorter "test timing" can be selected, so that the time per revolution of the circular cylinder is shorter, which can increase the resolution of the drying time measurement.

4. After the operation, do a good job of cleaning the drying Tester in time; after using it for a certain period of time, add lubricating oil to the moving part of the drying Tester in due course.

5. After turning off the power switch on the back of the automatic drying Tester, please wait for 10 seconds before turning it on again, otherwise it will easily cause display confusion. If the display error occurs occasionally during use, please turn off the power and wait for 10 seconds before restarting.

- 1ASTM D5895《Standard Test Methods for Evaluating Drying or Curing During Film Formation of Organic Coatings Using Mechanical Recorders》

- 2ISO 9117-4《Paints and varnishes - Drying tests - Part 4: Test using a mechanical recorder》

- 3DIN EN ISO 9117《Paints and varnishes - Drying tests - Part 4: Test using a mechanical recorder (ISO 9117-4:2012)》

- 4HG/T 5173-2017《Waterborne primer for application on rusty substrates》

- 5JG/T 210-2018《Primer for interior and exterior wall》

- 6JC/T 975-2005《Waterproofing coatings for concrete bridge and road surface》

- 7JC/T 2090-2011《Polymer modified cement slurry for waterproof》

- 8ASTM 《Standard Specification for Aluminum Particle-Filled Basecoat/Organic or Inorganic Topcoat, Corrosion Protective Coatings for Fasteners》

- 9JT/T 821.1-2011《Anti-corrosive coatings for concrete bridge surface.Part 1: Solvent based coatings》

- 10DL/T 2308-2021《Technical specification for conductive anticorrosion coating for grounding in power engineering》

ZGY

ZGY