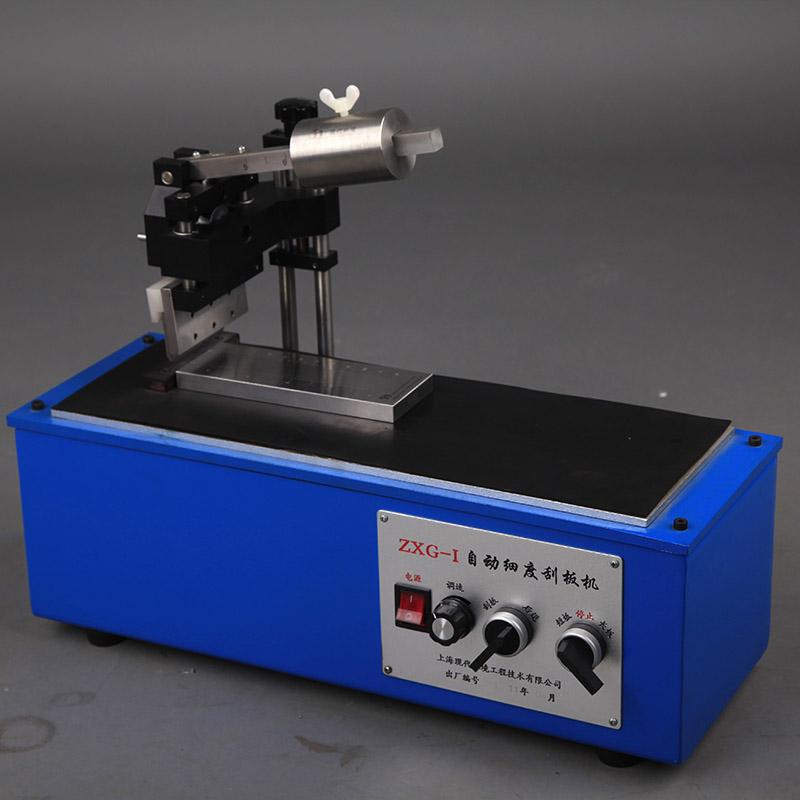

MODERNER ZXG-I automatic scraper, suitable for measuring the degree of material dispersion during the production and inspection of chemical raw materials

Moderner ZXG-I Automatic scraperSPEC

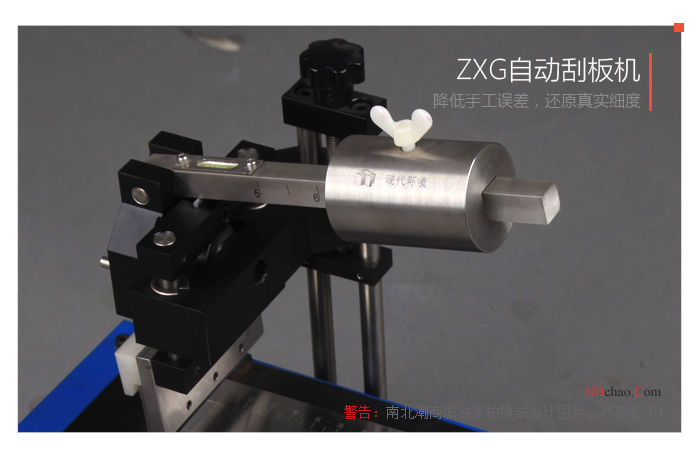

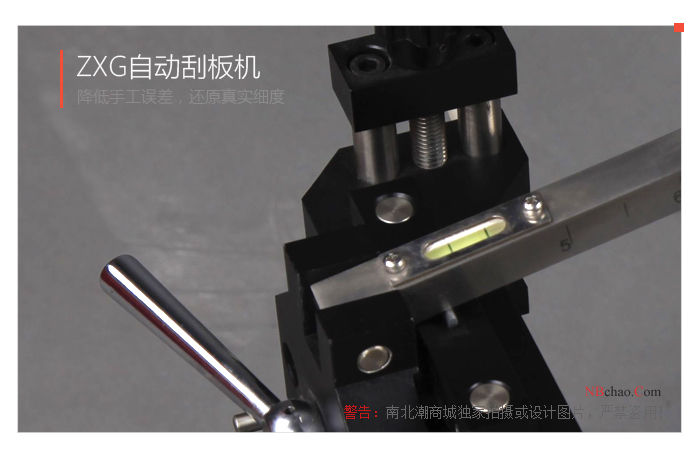

Moderner ZXG-I Automatic scraperDetails

Moderner ZXG-I Automatic scraperPacking list

- SKU

- NB000723

- Scratch speed

- 0~7m/min

- Maximum working stroke

- 200 mm

- Maximum drawdown blade load

- 8kg

- Motor Power

- 60 watts

- Power Supply

- 220V/50Hz

- Scraper size

- 500*250*365mm

Overview

In the production process of chemical raw materials such as coatings, pigments and inks, using a scraper Fineness Meter to measure the degree of material dispersion is a common method to evaluate dispersion and is one of the standardized methods for quality control. However, in order to obtain consistent dispersion determination results, not only well-trained and experienced operators are required, but also the operational fluctuations among operators must be within the allowable tolerance range. The ZXG-I automatic fineness scraper is a new tool provided to improve the evaluation method of the scraper Fineness Meter. The automatic fineness scraper completes the scraper operation by using mechanized scraper movement, thus avoiding the need for personnel The scraper operation fluctuates between intervals to improve the consistency of the judgment results.

Modern Environment ZXG-I automatic scraper is used in the production and testing process of chemical raw materials. Users should establish appropriate safety and protective measures and determine rules and regulations in accordance with relevant safety regulations before use. Safety issues related to contact with chemical raw materials should be established by the user and are beyond the scope of this manual.

The main technical parameters

| Scraper speed | 0~7m/min |

| Maximum working stroke | 200mm |

| Maximum scraper pressure | 8kg |

| Motor Power | 60 watts |

| using electric | 220V/50Hz |

| Dimensions | 500x250x365mm |

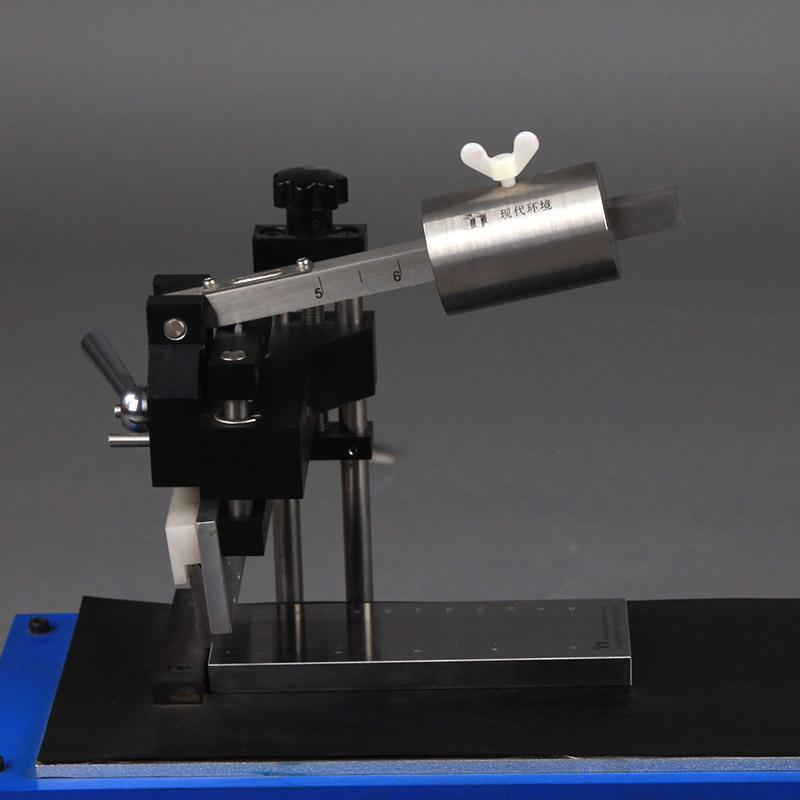

Structure diagram

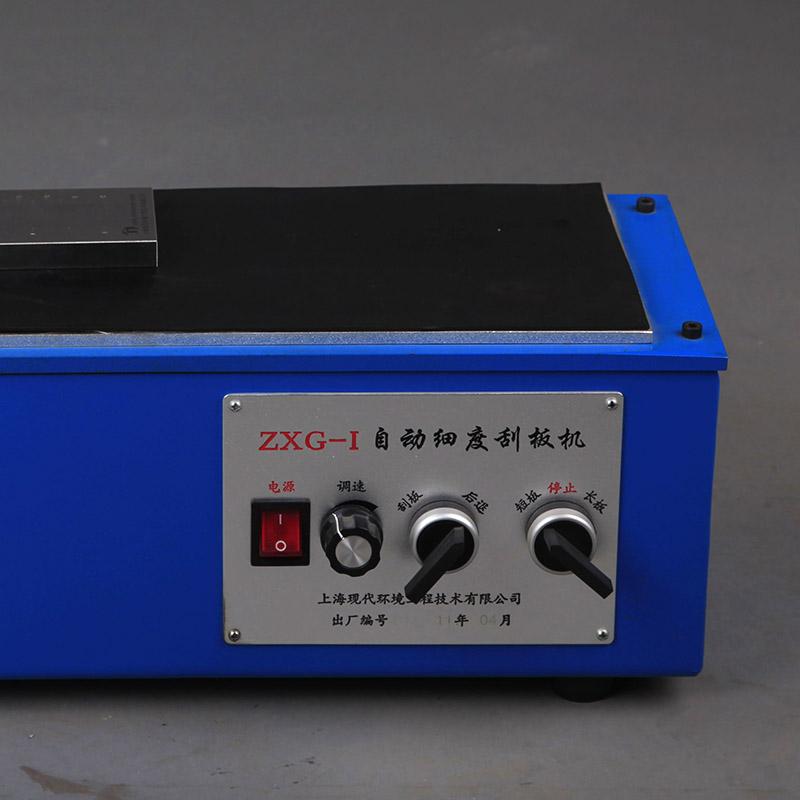

Instructions

1) The automatic fineness scraper machine is used in conjunction with the scraper Fineness Meter. The operation of the scraper Fineness Meter itself will not be described in detail here. The Grindometer is not provided with this machine, please order it separately as needed. Turn on the power and turn on the power switch on the "operation panel" to use the machine.

2) The scraper stroke end of the automatic fineness scraper machine is fixed, and the scraper stroke starting position is adjustable within the maximum stroke range. The automatic fineness scraper machine presets the second gear starting position according to the scraper specifications produced by Shanghai Modern Environment Company. The "short plate" file is suitable for the national standard specification paint fineness board and the ASTM standard specification fineness board, and the "long board" file is suitable for the national standard specification ink fineness board. When the "scraper mounting frame" is in the terminal position, select the "reverse" gear, and the scraper frame will retreat and stop at the set position according to the selection of "short board" and "long board". If a non-standard scraper is used and the set position is deemed inappropriate, you can select the "long plate" position before retreating, and then manually determine the stop position of the scraper holder through the "stop" position of the knob switch during the retreat process.

3) Before operating the scraper, place the "0" scale end of the fineness plate against the "terminal stop" and place the scraper on the magnetic "scraper mounting bracket". The "scraper mounting bracket" is suitable for scrapers produced by Shanghai Modern Environment Company and scrapers of ASTM standard specifications. The "pressure slider" is used to adjust the scraper pressure. The scraper pressure is determined by the viscosity of the sample: too much pressure will affect the service life of the scraper and scraper; too little pressure will cause the scraped sample to be unclear, which is detrimental to the evaluation. After installing the scraper, scraper and pressurized slider, turn the "knife lifting handle" backward to lift the scraper, turn the "lift adjustment knob" to raise the "scraper installation frame" so that the scraper will not touch the scraper when moving forward. (When turning, you can use your other hand to gently lift the "pressure slider" so that the knob does not feel too tight when turning). Turn the knob to the "scraper" position, the scraper frame will advance and stop at the end of the stroke. Turn the "knife lifting handle" forward to lower the scraper, adjust the "lift adjustment knob" so that the scraper contacts the scraper and the horizontal bubble on the pressure rod is roughly centered, and tighten the supporting screw. Then turn the "knife lifting handle" back again to make the scraper leave the scraper to complete the adjustment before use.

4) Before adding samples to the scraper, you can move the scraper holder to the end (turn the knob to the "scraper" position), so that it is more convenient to add samples. According to the specifications of the scraper used, select the "short board" or "long board" gear. After adding the sample, turn the knob to the "reverse" position and reset the scraper holder to the starting position. Turn the "knife lifting handle" forward to press the scraper on the scraper, and turn the knob to the "scraper" position to complete the scraper movement.

5) After the scraper holder stops, turn the "knife lifting handle" backwards to lift the scraper, and you can visually judge the dispersion fineness (you can also move the scraper holder back and then make a visual judgment). After the judgment is completed, clean it before proceeding to the next operation.

6) The scraper speed can be adjusted with the "speed adjustment" knob. The "scraper/reverse" knob switch is used to advance and reset the scraper frame: select the "scraper" position, and the scraper frame will move toward the end of the stroke no matter where it stops. Select the "Reverse" gear, and the movement of the scraper rest depends on the position of the "Short Plate/Stop/Long Plate" knob switch: Select the "Short Plate" or "Long Plate" gear, the scraper frame will stop at the set position; when the scraper frame Before retreating to the set position, turn the knob to the "stop" position, and the scraper will stop at the current position.

Precautions

1. The automatic fineness scraper should be used under laboratory temperature and humidity conditions.

2. The motor of the automatic fineness scraper machine has an electronic braking circuit. If necessary, do not make instantaneous scraper-reverse conversion movements to protect the service life of the electrical components.

3. After use, please remove the "pressurized slider" or place an object such as cork under the "scraper mounting frame" to reduce the lateral force on the scraper frame lifting slide rod.

4. After using the automatic fineness scraper, clean it in time. After using it for a certain period of time, please lubricate the motion guide rail in time (from the rear opening or remove the upper cover).

5. When the machine is started for the first time when the temperature is low, the lubricating oil in the reducer will become thicker, which will affect the running speed of the motor. You can select the "long plate" gear and do a few more reciprocating movements to stir up the lubricating oil and make it thinner, until the motor speed is normal before starting to work again.

ZXG-I

ZXG-I